Cub Cadet MTD P71 Series User Manual

Page 84

P71 Series Vertical Shaft Engines

78

5.

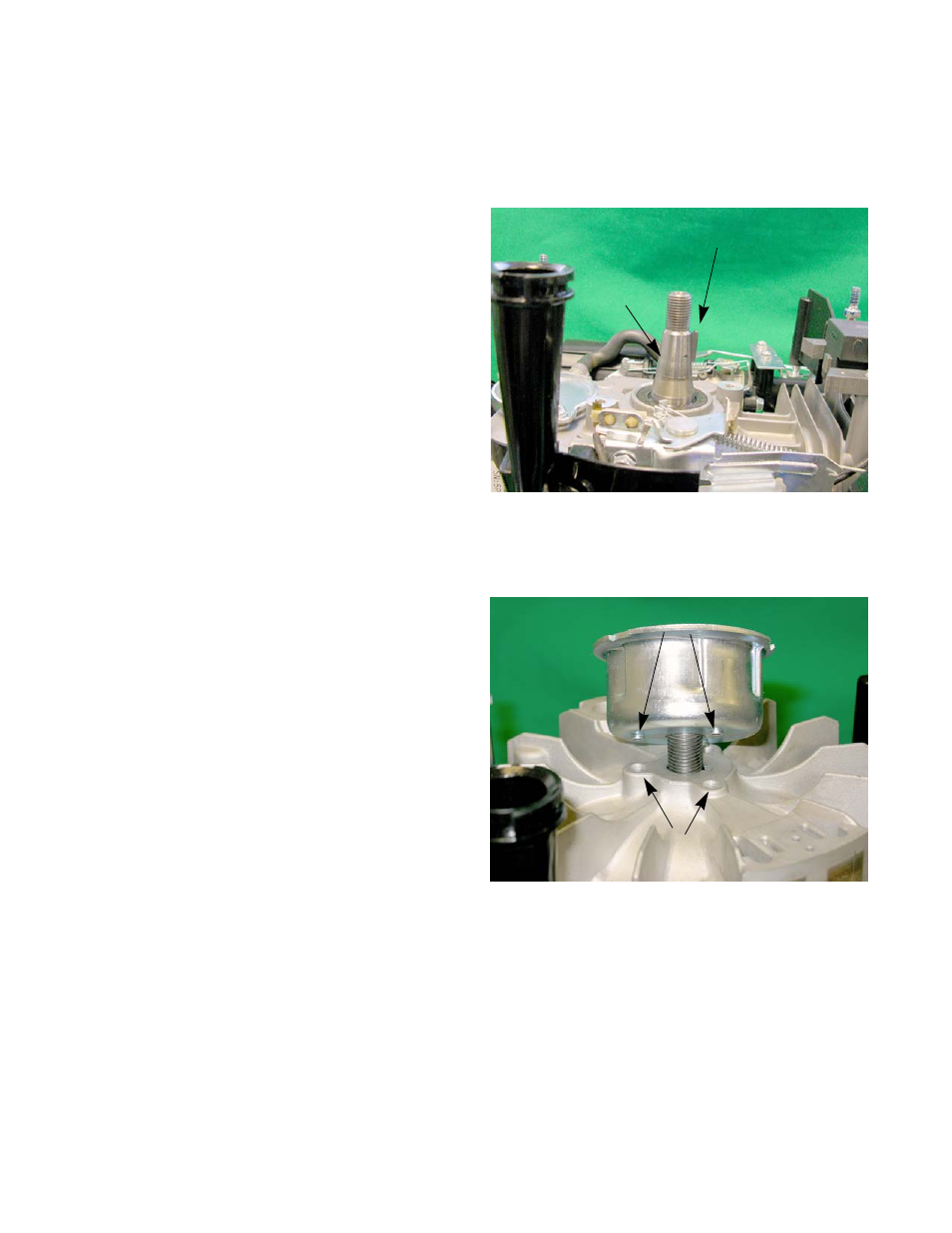

Inspect the key, keyway, and tapered mating sur-

faces of the flywheel and crankshaft. See Figure

7.16.

NOTE: If the key is damaged it must be replaced. If

there is damage to the crankshaft key way,

the engine must be short blocked because

crankshafts are not available as a service

part.

IMPORTANT: The taper in flywheel and the on the

crankshaft must be clean and dry.

The flywheel is held in place by the

friction fit between the flywheel and

the crankshaft, not the key. The key

is only to guide the flywheel to the

proper position until it is torqued

down.

6.

On installation, confirm that the key is properly

seated (the flat of the key parallel with the threaded

section of the crankshaft) in the key-way, and that

the tapers are fully seated. Key or keyway failure

may result from improper seating.

7.

Install a starter cup by placing the starter cup on the

flywheel. Allow the protrusions on the bottom of the

starter cup to rest inside the dimples in the flywheel.

See Figure 7.17.

8.

Install the flywheel nut to a torque of 33 - 41 ft lbs

(45 - 55 Nm).

9.

If removed, install the ignition module by following

the procedures described in the Ignition Module

section of this chapter.

10.

Adjust the air gap by following the steps described

in the ignition module section of this chapter.

11.

Reassemble the engine.

12.

Test run the engine in a safe area before returning it

to service.

Figure 7.16

Key flat parallel to the threads

Taper

Figure 7.17

Starter cup protrusions

Flywheel dimple