Transaxle replacement: hydrostatic gt – Cub Cadet SLT1500 Series User Manual

Page 68

Series 1000 and 1500

64

•

Install the screw O-rings.

•

Install the lower cover without sealant, to align

the cover and manifold.

Secure it with the 11 perimeter screws.

•

Remove the lower cover, and apply sealant to

the mating surfaces where the cover meets the

transaxle housing.

•

Install the lower cover, tightening the screws to a

torque of 135 to 185 in-lbs.

•

Position a new O-ring seal in the charge pump

housing, and place the gerotor in the housing. If

one edge of the outside of the gerotor is slightly

rounded, it goes into the housing first. The flat

edge rides against the lower cover.

•

Position the charge pump, rotating as necessary

to align the gerotor pump with its drive shaft and

to align the charge pump housing index marks.

•

Install the two socket head cap screws that

secure the charge pump, and tighten them to a

torque of 87 to 108 in-lbs.

33.19. Allow the bottom cover sealant to cure according

to the sealant manufacturer’s instructions, then

fill the transaxle with fluid.

33.20. Any time the transaxle fluid has been refilled, it

will be necessary to purge the air from the

pumps. Air in the drive system will cause:

•

Noisy operation

•

Lack or loss of power

•

High operating temperatures

33.21. To purge the air from the hydraulic system in the

transaxle:

•

Open the relief valve.

•

Start the engine.

•

Slowly cycle the drive pedal from full speed for-

ward to full speed reverse 5 or 6 times, taking

about 10 seconds to complete a single cycle.

•

Stop the engine and check the fluid level at the

fluid level port near the back of the right side

axle housing. The plug can be removed with a 1/

4” Allen wrench. Top-up as necessary.

•

Close the relief valve.

•

Start the engine.

•

Slowly cycle the drive pedal from full speed for-

ward to full speed reverse 5 or 6 times, taking

about 10 seconds to complete a single cycle.

•

Stop the engine and check the fluid level at the

fluid level port near the back of the right side

axle housing. The plug can be removed with a 1/

4” Allen wrench. Top-up as necessary.

•

Repeat as necessary until the transaxle oper-

ates normally.

33.22. Refer to Hydro-Gear manual BLN-52359 for

complete repair instructions.

34.

TRANSAXLE REPLACEMENT:

HYDROSTATIC GT

34.1. Warrantable failures on Cub Cadet tractors are

to be repaired by replacing the transaxle. Failed,

warrantable transaxles will be called-back

through Cub Cadet’s vendor recovery system.

Failures of Hydro-Gear transaxles are rare.

34.2. Outside of warranty, Hydro-Gear transaxles may

be repaired or replaced at the discretion of the

customer and servicing dealer.

34.3. Before condemning a transaxle, eliminate all

possible external performance issues:

•

Dragging brake

•

Maladjusted linkage

•

Partially open relief valve

•

Slipping traction drive belt/ low engine speed

34.4. Remove the cutting deck to gain access to the

linkages that will need to be disconnected.

34.5. Lift and safely support the rear of the tractor.

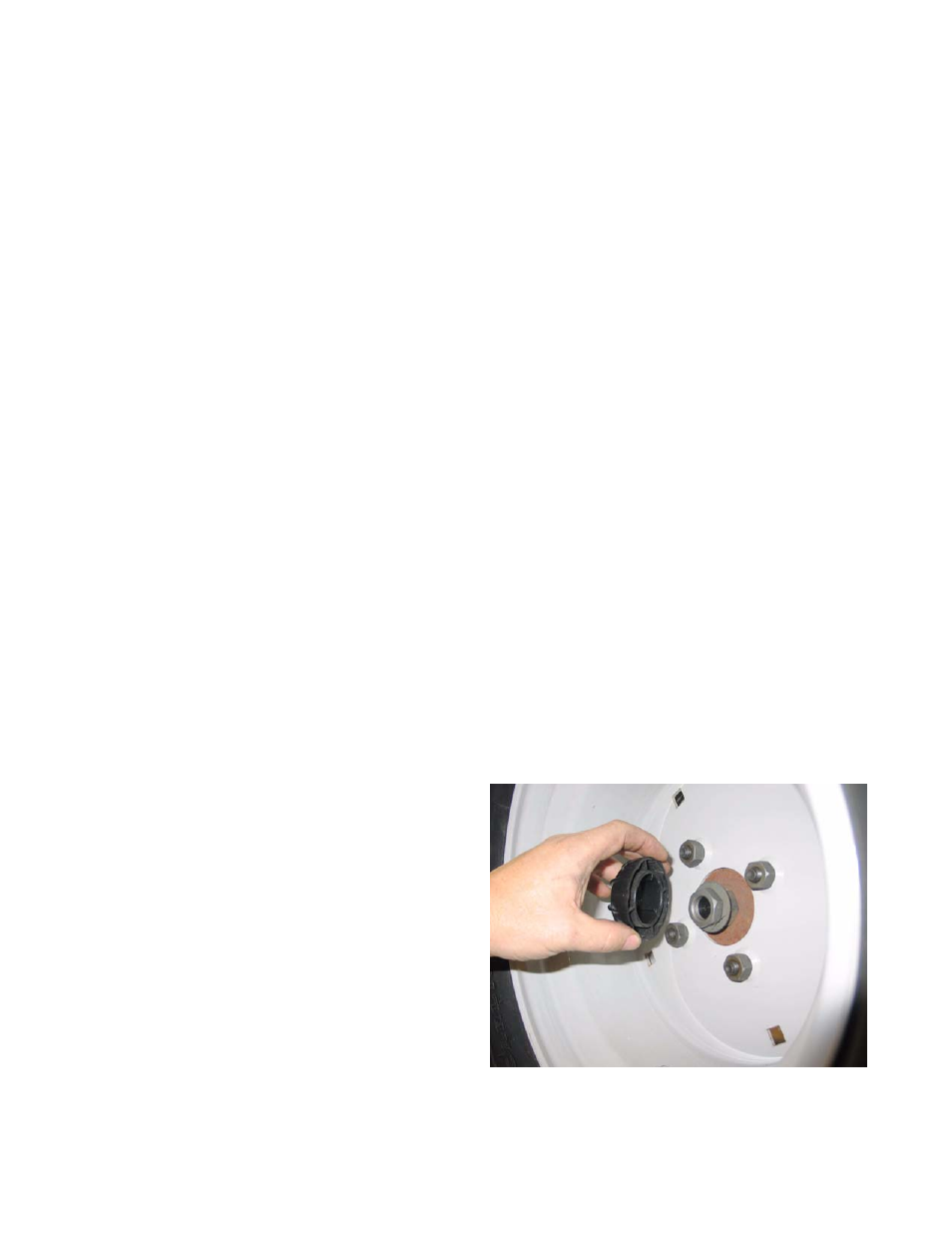

34.6. Remove the rear hub caps, then the rear wheels

using a 3/4” wrench. See Figure 34.6.

Figure 34.6