Warning – Cub Cadet 190-291-100 User Manual

Page 15

15

4.

Reposition the caster wheels and roller so that

they are appoximately 1/2 inch above the ground.

5.

For subsequent minor adjustments from this

position, use the tractor lift system to raise the deck,

then turn the adjustment knob as necessary to

attain the desired height setting (one full turn

equals approximately 1/4"). Reposition the caster

wheels and rollers if necessary.

NOTE: To use the caster wheels/rollers for setting the

cutting height on tractors equipped with the deck

downstop, make certain to lower the downstop using

the height adjustment knob. Then follow the previous

instructions for setting the cutting height using the

caster wheels and rollers.

Figure 26

RAISE

LOWER

HEIGHT

ADJUSTMENT

KNOB

SECTION IV. MAINTENANCE

A. CLEANING AND BLADE CARE

WARNING

Before performing any maintenance, place the

PTO switch in the “OFF” position, engage the

parking brake lever, turn the ignition key to the

“OFF” position and remove the key from the

switch. When servicing the mower deck, be care-

ful not to cut yourself on the sharpened blades.

Clean the underside of the mower deck at the end of

the mowing season or when buildup of cut material on

the underside is noticed.

Once a month remove the thumb screws, bell washers,

and belt covers (Refer to Figure 29) to remove any accu-

mulated grass clippings from around the spindle pulleys

and V-belt. More often when mowing tall, dry grass.

The cutting blades must be kept sharp at all times. Sharp-

en the cutting edges of the blades evenly so that the

blades remain balanced and the same angle of sharp-

ness is maintained. If the cutting edge of a blade has

been sharpened to within 5/8 inch of the wind wing radius

(See Figure 27), it is recommended that new blades be

installed. New blades are available at your authorized

dealer.

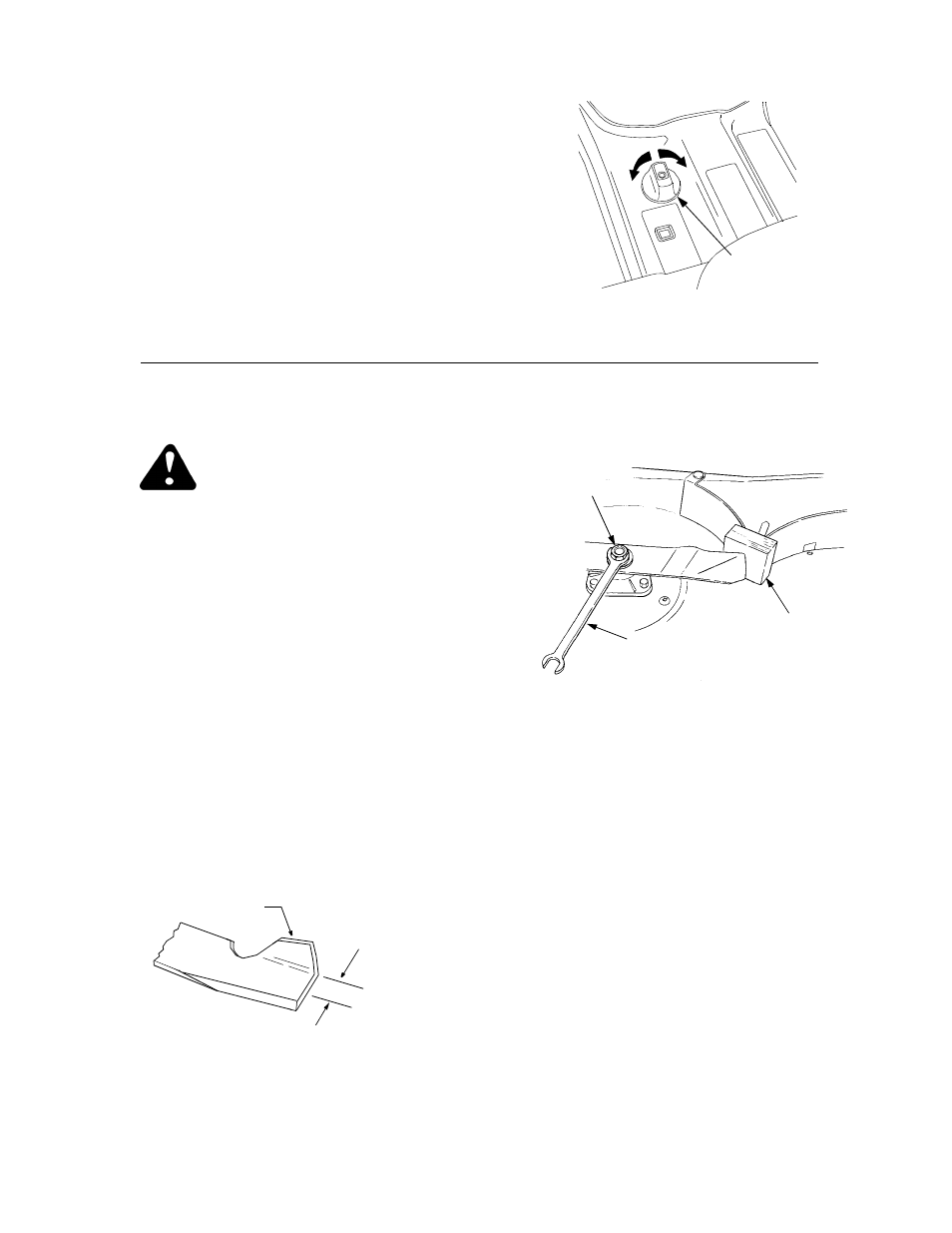

Figure 27

When removing the blades, use a 1-1/8 inch wrench to

hold the head of the spindle bolt while loosening the

hex nut securing the blade. A block of wood may be

placed between the deck housing and the cutting edge

of the blade to assist in removal of the hex nut (Refer

to Figure 28).

Figure 28

When reinstalling the blades, be sure they are installed

so that the wind wings are pointing upward toward the

top of the deck. Tighten the nuts to 90 to 110 ft-lbs.

(122 to 149 N·m).

After replacing the blades, apply grease to the

exposed threads at the bottom of the spindle bolts to

prevent rust buildup.

B. LUBRICATION

After every 10 hours of operation and/or before putting

the deck into winter storage, lubricate the spindle

assemblies and the spindle belt idler arm with 251H EP

grease or an equivalent No. 2 multipurpose lithium

grease. The lube fitting for the outer spindles can be

accessed by removing the button plugs in the belt

covers. Use grease liberally. Excess grease will be

expelled from the inverted upper seals of the spindle

assemblies. Listen for the muffled crackling noise of

grease being expelled through the seal to indicate the

spindle assembly is fully greased (Refer to Figure 29).

Apply grease to all other lube fittings after every 50

hours of operation. Refer to LUBRICATION GUIDE.

WIND

WING

5/8" FROM

RADIUS

HEX NUT

1-1/8" WRENCH

WOOD BLOCK

IN POSITION