Checkline BLL User Manual

Page 5

Electromatic Equipment Co., Inc.

-12-

15.0 MOST COMMON REASONS FOR MISS READINGS

•

Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements. The storage of cold material in a warm storage area usually

creates condensed water which may lead to major measuring errors.

•

Not adjusted material under test

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

•

Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

•

Wet or mouldy material

•

Frozen measuring material

•

Water film at the measuring head

After measuring wet material a water film can arise on the sensor head. This

could lead to a too high result in the following measurement. After measuring

wet material clean both black plastic parts accurately with a dry cloth.

ATTENTION: Risk of injury by measuring head!

Keep away from children under 16 years!

Electromatic Equipment Co., Inc.

-5-

5.0

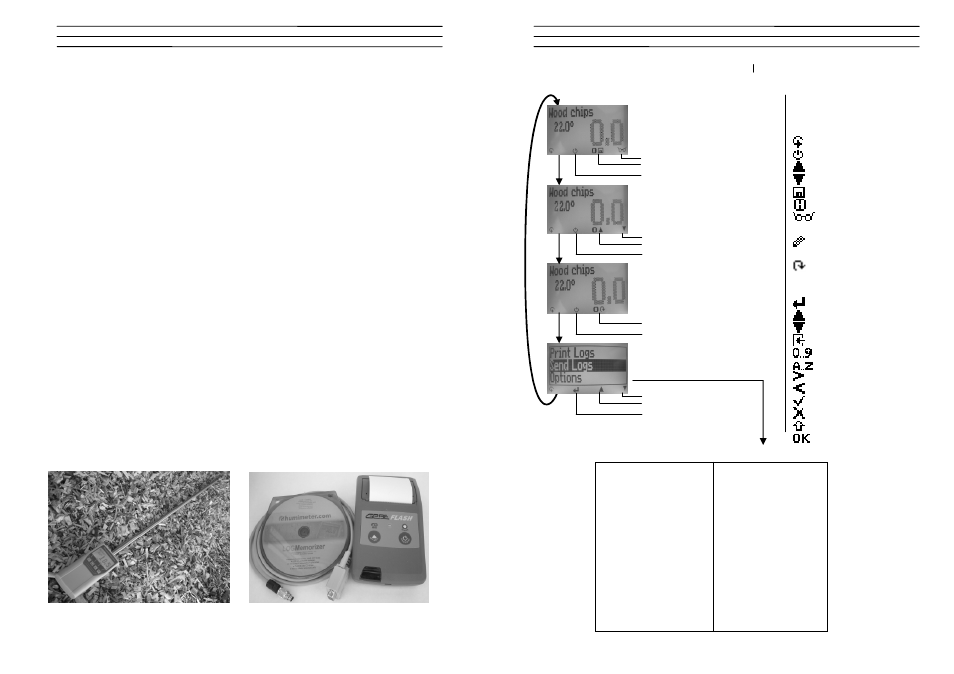

MENU LEVEL OVERVIEW

Next calibration curve

Previous calibration curve

Power off (3 sec.)

Watch the saved data (logs)

Save new value

Power off (3 sec.)

Type selection menu

Store menu

Main menu

Switch upper

Switch lower

Open this menu / Enter

Keypad symbols

Measuring window:

Rolling Menu

Power ON / OFF

Switch upper

Switch lower

Save

Hold

Watch the

saved data

Suppliers data

can be added

Rotate display

Menu:

Enter

Switch upper

Switch lower

Exit

Enter numbers

Enter letters

Next or right

Left

Yes

No

Shift

OK

Edit Logs

Manual Logs

Clear Logs

Print Logs

Last Log

All Logs

Clear Logs

Send Logs

Manual Logs

Clear Logs

Options

Status

Options

Date / Time

Log Time

Language

Unlock

°C / °F

o Userlevel

BL On Time

Auto Off Time

Materialcalib.

Password

Reset

Overview main menu

Additional function

menu

Rotate display

Power off (3 sec.)