Checkline BM User Manual

Page 2

– 2 –

1.0 INTRODUCTION

A selection of calibration curves are permanently strored in the BM2.

However, if none of the provided calibration curves suit the material to be

measured, the user can create and store a new calibration curve for use in these

special cases.

The following pages provide instructions for creating a user-defined

calibration curve.

– 7 –

To save the values you have to leave the “Moisture” menu item by

pressing the shift button (

) first, and then the symbol with the

opened door (

). .

To be sure that all values are in the correct order and are correct, double

check the whole values in the calibration curve!

2.8 Temperature

compensation

For the temperature compensation, a factor (TK1) is pre-programmed,

which can also be altered manually. However we recommend using

the standard compensation factors which are calculated and tested for

materials with a temperature sensitive calibration curve. If you do not

know the compensation factor of your product we recommend using

the standard settings of the BM2 for temperature compensation.

To get an exact TK1, take three samples with exactly the same moisture

content and pack them in sealed plastic bags. Now heat and cool the

samples to different temperatures. (also the BM2)

Bag1

23 °C

Bag 2 08 °C

Bag 3 40 °C

It is important that the samples after moistening and drying for long

enough can align and cool. Airtight seal!

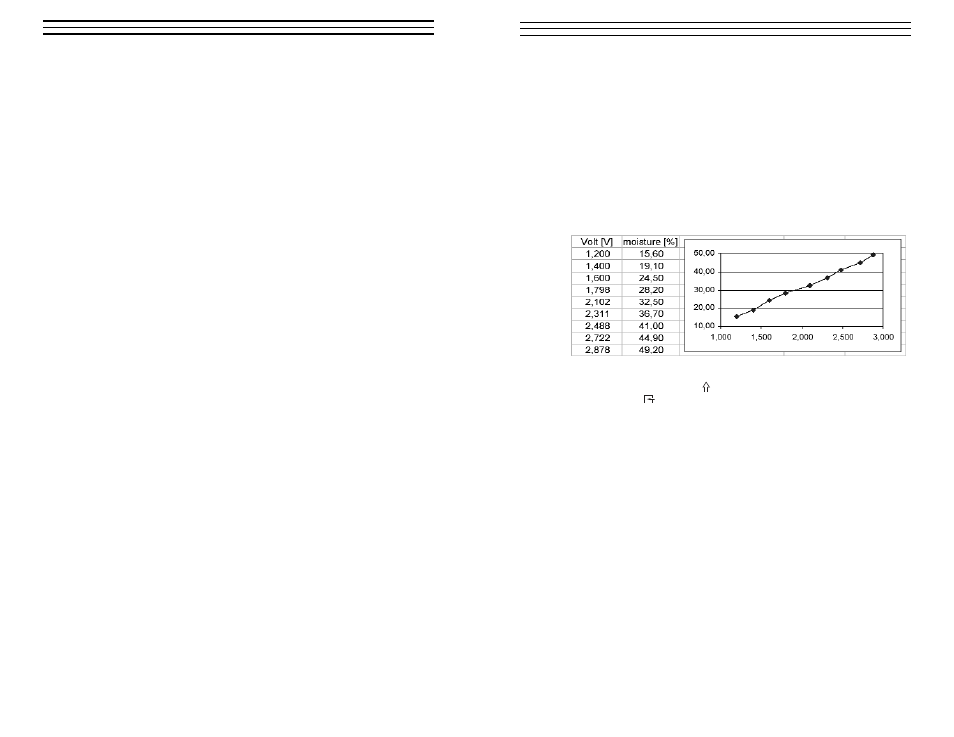

There are a maximum of 16 index points available. However, there

should be a maximum and minimum also registered. As many points as

possible over the entire measuring range should be included.

We recommend that the captured voltage and moisture contents are

inscribed in a graphic. Not linear points can be corrected. The values

should be (as shown in the example below) almost on a straight line.