Checkline BM User Manual

Checkline Measuring instruments

– 1 –

TABLE OF CONTENTS

1 . 0

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2.0 Create the calibration curve . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

2.1 Define the fill quantity . . . . . . . . . . . . . . . . . . . . . .

3

2.2

Prepare the samples . . . . . . . . . . . . . . . . . . . . . . . .

3

2.3

Determination of reference moisture content . . . . .

4

2.4

Determination of the acual moisture content . . . . . .

4

2.5

Unlock the BM2 . . . . . . . . . . . . . . . . . . . . . . . . . .

5

2 . 6

Change the calibration curve name . . . . . . . . . . . . .

5

2.7 Take over the values . . . . . . . . . . . . . . . . . . . . . . . .

6

2.8 Temperature compensation . . . . . . . . . . . . . . . . . . .

7

2.9

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . .

8

2.10 Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

– 8 –

With the following calculation the right TK1 can be calculated:

For example: Measure with your BM2 at 23°C a moisture content of 30%

and by the sample in the fridge (at app. 8°C) just 20%.

NOTE: Before measuring allow your BM2 to become conditioned to

the sample temperature.

2.9 Measuring

range

In the menu item “Valid” is the validity of the calibration curve given. A

valid measurement is shown in the measuring window black, a invalid is

sown gray. This feature can be best explained by an example.

The goal is a valid range from 5% up to 25% moisture content because

for certain materials readings above 25% lose accuracy

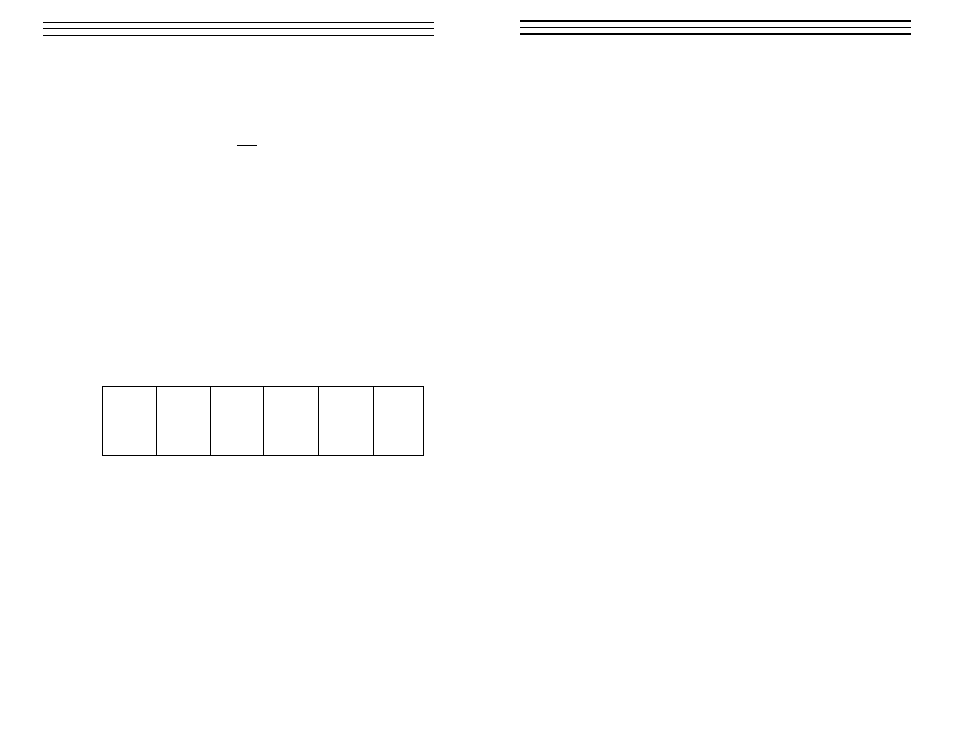

Enter the following values in the shown order:

idx idx idx

idx idx

idx

(1)

(2)

(3)

(4)

(5)

(6)

Idx(1)

Idx(2)

Idx(3)

Idx(4)

Idx(5)

Idx(6)

50%

25.1%

25%

5%

4.9%

0%

0

0

1

1

0

0

The measruing range should e defined in the area of the measured

samples.

2.10 Completion

If all values of the created calibration curve are stored in the BM2

device, you can measure the material with the new calibration curve.

TK1=

30

=1.5

20