0 calibration curves – Checkline LM6 User Manual

Page 4

– 3 –

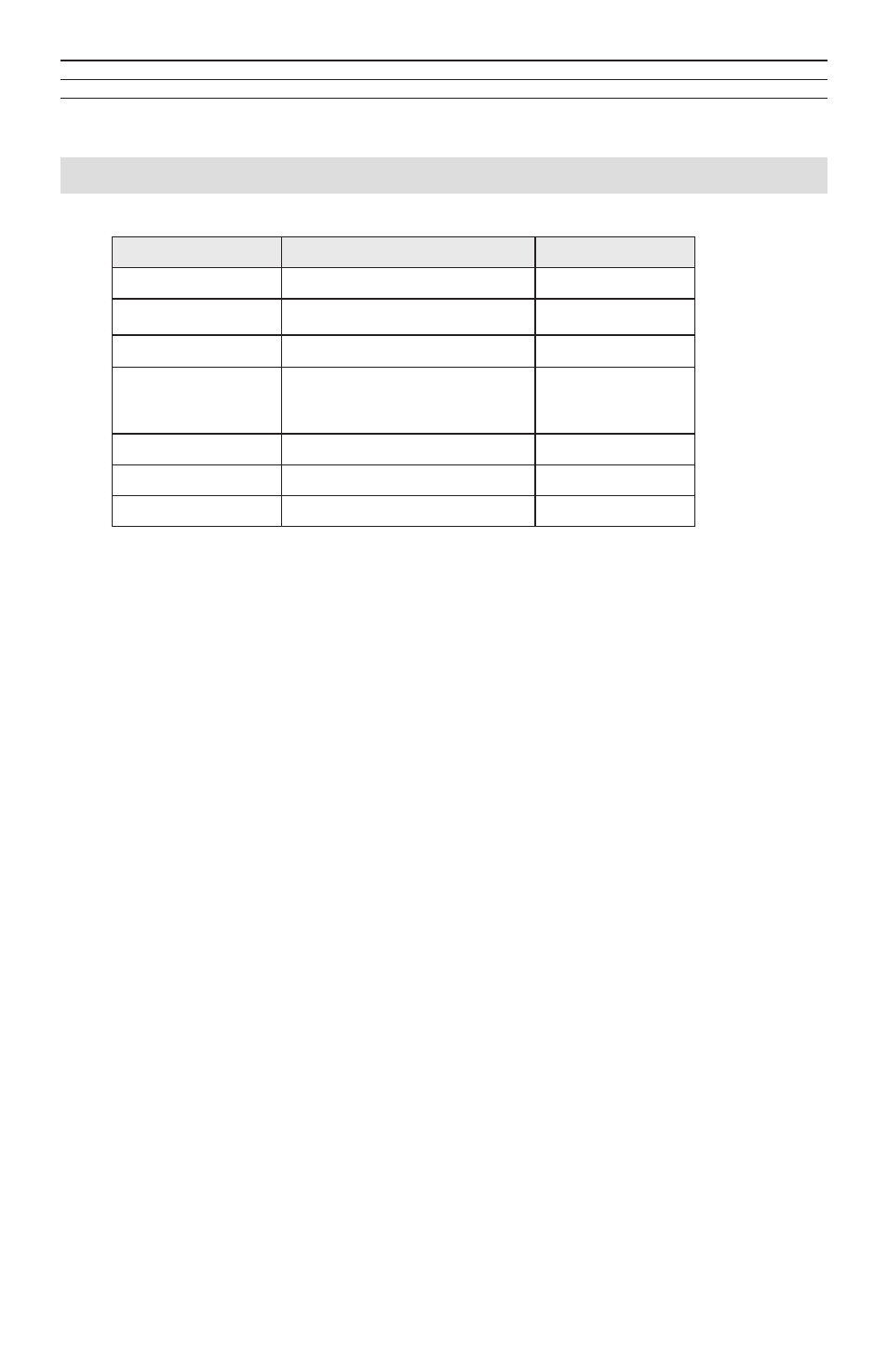

2.0 CALIBRATION CURVES

NAME

CALIBRATION CURVE

DENSITY

Leather LD

Leather of low density

0.55 g/cm³

Leather CR

Leather chrome tanned

0.60 g/cm³

Leather MD

Leather of medium density

0.65 G/CM³

Leather FOC

Leather free of chrome, fire

protection leather

0.70 g/cm³

Leather HD

Leather of high density

0.75 g/cm³

Leather VHD

Leather of very high density

0.80 g/cm³

Reference

Only for checking the instrument

2.1 Selection of calibration curves

Due to different manufacturing methods and different densities of the leather there is no

standardised allocation of calibration curves.

In the above list of calibration curves you can find information regarding manufacturing

methods and density that enables a preselection of the calibration curve.

To ensure the best accuracy of your measurement, we recommend to carry out a

comparison measurement by kiln-drying (norm DIN 53304) once:

1. Take a leather pile of 10-15mm of the format A6 with average moisture content.

2. Measure the water content of this leather pile using all available calibration curves

and write down the measuring results of the different calibration curves.

3. Take the 2 top leather pieces of the pile and carry out a reference measurement

according to DIN 53304.

4. Compare the determined reference water content with the measuring results of the

different calibration curves. Use the calibration curve with the measuring result

nearest to the reference water content.