Zero gain – Checkline TS2P User Manual

Page 9

– 8 –

4.0 INTERNAL ADJUSTMENT OF THE SENSORS

If the sensor has been delivered with a display unit, the ZERO and GAIN

adjustments should only be carried out with the supplied display unit.

All tension meters are calibrated with standard material, such as polyamide

monofilament (PA), according to the factory procedure; the material path is

vertical. Any difference in process material size and rigidity from the standard

material may cause a deviation of the accuracy.

In 95% of all industrial applications, the factory calibration has been proven to

provide the best results and is used for comparative purposes.

If required you can also operate the sensors with a material path other than vertical.

Should the process material differ significantly from the factory calibration material

in size, rigidity or shape, we recommend special calibration using customer

supplied material. If the material path is other than vertical or if the process

material deviates significantly from the factory calibration material, you need to

carry out static ZERO and GAIN adjustment as described in sections 4.1 and 4.2.

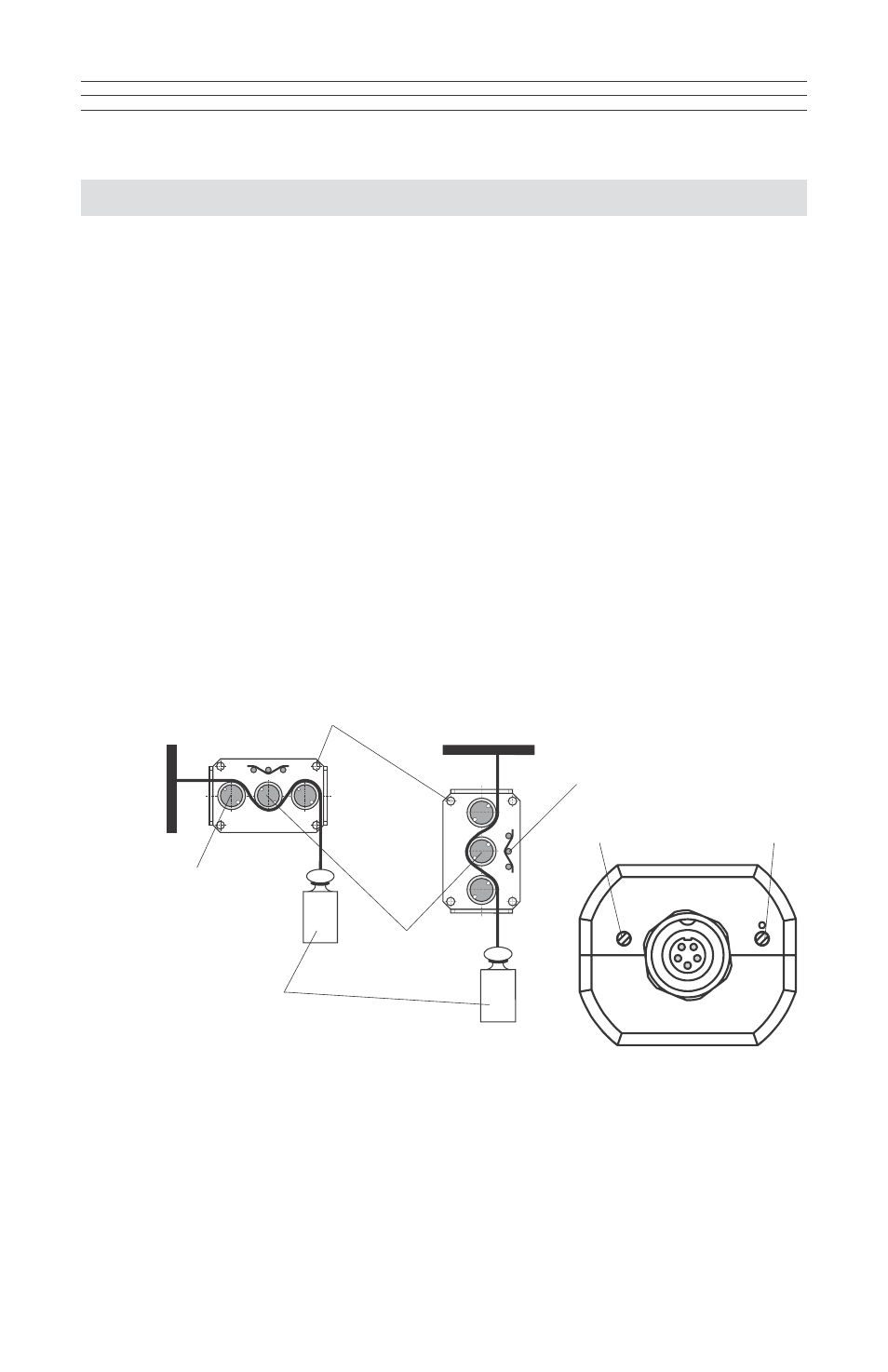

4.1 ZERO Adjustment

Mounting holes

4x

Weight

Material path symbol

Measuring

roller

Guide rollers 2x

ZERO

GAIN

1. Install the sensor in the desired position at the

measuring location using the provided mounting holes.

2. Allow approximately ten minutes for thermal stabilization of the sensor.

3. Thread the process material through the measuring and guide rollers, following

the material path symbol on the front of the sensor.