Checkline TI-45N User Manual

Page 7

TI-45N Operating Instruction Guide

7

4.4

Turning The Power ON

After connecting the probe as described in section 4.4, turn on the power by

pressing the

POW

key. The current acoustic velocity setting will be momentarily

displayed prior to entering the Measurement Mode (Mode H). The display should

then read 0.000 inch (or 0.00 mm).

If the Good Coupling Indicator is flashing on and off, the red transmit connector

of the probe is not connected properly.

4.5

Turning The Power OFF

The Power will turn off automatically after three (3) minutes of non-use. To

manually turn off the power, press & hold the

POW

key for 3 sec., then release.

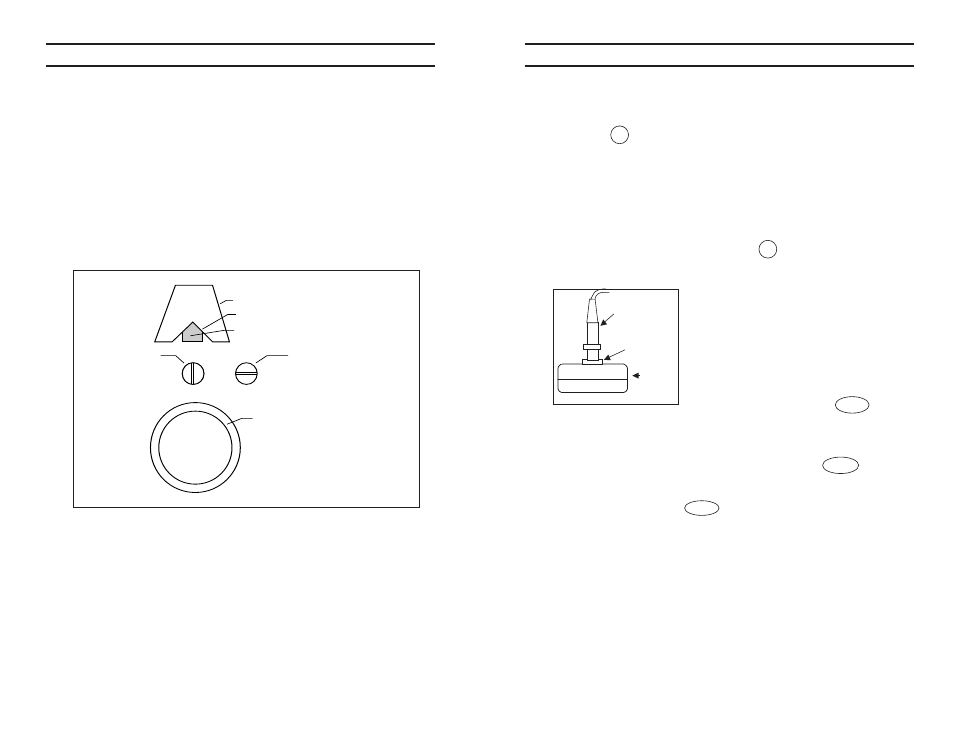

4.6 Zero Adjustment

This operation adjusts the zero point of the probe.

Zero adjustment data is stored in the instrument. It

is recommended that the zero adjustment data be

refreshed once a day, preferably before starting the

day’s work.

1. Apply couplant on the test plate surface and

place the probe on it.

2. Make sure the probe is in good contact with the

test plate surface and press the

ZERO

switch.

3. The zero adjustment procedure takes place and the display reads 0.197" or

5.00 mm when the process has been successfully completed.

NOTE: When the sonic velocity is set to a value other than 5390 m/s, the

display reads 0.197" or 5.00 momentarily when the

ZERO

switch is

pressed. Zero adjustment is nonetheless proceeding correctly.

If the material to be tested is significantly larger or smaller than 0.197"

or 5.00mm, and the ZERO switch is pressed, the display will read ----

and the zero adjustment process becomes invalid. In this case, the zero

adjustment should be made on a sample of known thickness of the test

material itself.

4.7 Using Couplant Fluid

Apply couplant fluid to the measuring surface before measurement. The couplant

eliminates air between the probe and test surface, promoting the transmission of

the ultrasonic pulse.

NOTE: Never use organic solvents, including thinners and alcohols.

The surface must be cleaned of couplant after measurement.

Probe

Te st plate

Thickness

gauge

TI-45N Operating Instruction Guide

18

7.3

Measurement Of Pipes Or Cylindrical Objects

When using a TI-45N Gauge to measure the wall thickness of pipes it is

highly recommended that the optional spring-loaded shell attachment be used.

It is supplied with a v-notch at the bottom of the shell attachment which greatly

helps maintain a stable right-angle probe position during measurement on

cylindrical surfaces.

Pipes with outer diameters less than 1 inch (25 mm) cannot be measured.

The orientation of the probe is important when measuring wall thickness of

pipes. The centerline of the probe face (separating the two sections) should

be arranged so that it is parallel to the length of the pipe as illustrated below.

Removable Shell Attachment (optional)

V-Notch

Probe

Pipe Wall

Open End

of Pipe

INCORRECT

Positioning of

Centerline of

Probe

CORRECT

Positioning of

Centerline of

Probe