Checkline TI-45N User Manual

Page 6

TI-45N Operating Instruction Guide

6

4.0

G

ETTING

S

TARTED

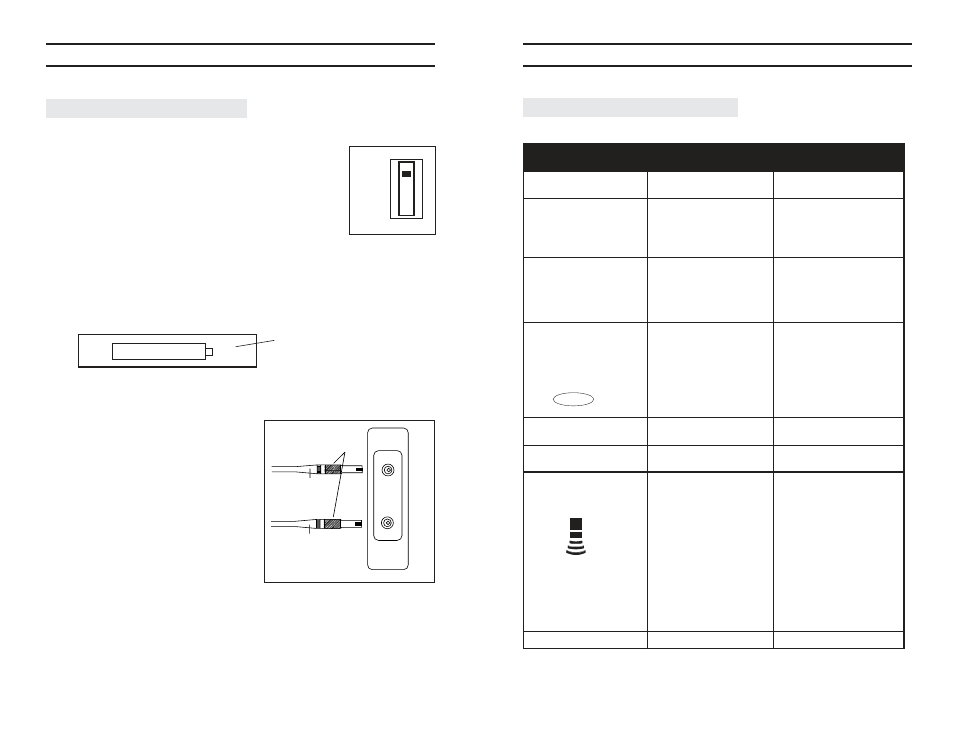

4.1 Setting Units Of Measure

Remove the Battery Cover on the back side of the gauge

by pressing it down with your thumb and sliding it in the

direction indicated by the arrow. The Units Selector Switch

is located in the Battery Compartment. Slide the switch to

either the Inch (up) or mm (down) position as desired.

Inch is the factory default unit of measure.

4.2 Installing The Battery

Remove the Battery Cover on the back side of the gauge by pressing it down

with your thumb and sliding it in the direction indicated by the arrow. Place

one (1) AA-size battery (1.5 Volt) into the battery compartment in the

orientation shown on the sketch. Replace the Battery Cover.

4.3

Connecting The Probe

Grasp the knurled aluminum shell of

the green colored connector on the

probe cable. Insert connector into the

upper receptacle marked “R” (Receive).

Insert the red connector into the

receptacle marked T” (Transmit).

Refer to illustration at right.

AA Battery

mm

Inch

+

–

Correct Battery Orientation

Battery

Compartment

Green

Green

Red

Red

Knurled Aluminum Shells

TI-45N Operating Instruction Guide

19

8.0 T

ROUBLE

-S

HOOTING

G

UIDE

Description of Problem

Possible Cause

Action To Be Taken

Gauge will not power

Battery voltage may be

Replace with new AA

up

too low

battery

Gauge will not power

• New battery may be

• Check battery voltage

up even though battery

too weak

(should be

≈

1.5 Volt)

has been replaced

• Back-up battery (lithium)

• Return gauge for a new

could be too weak

lithium battery

Good Coupling

• Probe or cable could be

• Clean probe & surface

Indicator flashes on/off

defective

and retry measurement

• Foreign substance may

• Return to manufacturer

be trapped between

for inspection/repair

probe and sample

Good Coupling

• Insufficient couplant fluid

• Add more couplant

Indicator not shown

• Paint or coating is too

• Grind off paint and/or

thick or voids and/or

corrosion

corrosion lies under paint

“......” is displayed

Probe could be degraded

Return to manufacturer

when ZERO key is

or defective

for inspection or repair

pressed

Displayed thickness

Acrylic probe face is

Carefully sand face of

value is unstable

deteriorated

probe using #500 paper

Can’t obtain measure-

Pipe diameter (OD) may

Consult factory

ment on small dia. pipe

be less than 1”

(25 mm)

Coupling indicator does

• Insufficient amount of

• Apply additional couplant

not appear while measure-

couplant

ment is being taken

• Test material surface is

• Grind/polish measuring

too rough

surface to 50-100-s

smoothness

• Test material bottom

• Change measurement

surface is too rough

point

• Too much ultrasonic

• Change measurement

attenuation due to

point

material composition

• Test material thickness is

• Change measurement

outside the proper

point

measuring range

Fluxuating readings

Defective probe

Return to manufacturer