Checkline TI-25LT User Manual

Page 7

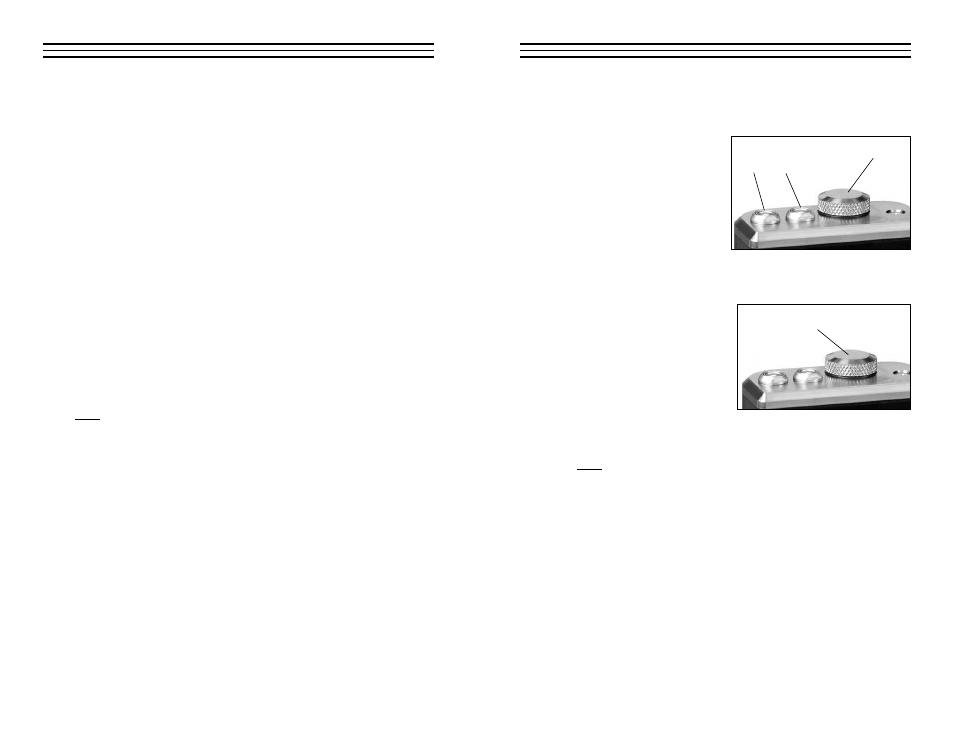

3.7 Probe Connector Receptacle

Located on the top edge of the TI-25LT housing are the receptacles for the

probe and the probe zero plate.

The connectors for the probe

are non-polarized so the con-

nector at the end of the probe

cable can be inserted into

this receptacle in either

orientation. Make sure the

connector is “well seated” in

the receptacle.

3.8 Battery Compartment (Changing The Battery)

The battery compartment is

located under the probe zero

test plate. To open the battery

compartment, unscrew the

probe zero plate by rotating it

counterclockwise. The TI-25LT

operates on two (2) AA

Batteries (1.5 V). If desired,

rechargeable batteries may be

used.

The TI-25LT is shipped with the batteries installed. Insert batteries in the

polarity indicated on the rear label.

Note: When the display elements begin to flash off and on repeatedly, the

batteries are low and should be replaced.

Battery Cover

Probe Receptacles

Probe Zero

Plate

– 7 –

– 10 –

5 .0

QU I CK START I N ST RU CT I ON S — ST EEL T H I CK N ESS

1. Turn on the power by pressing the ON/OFF key.

2. Plug the probe cable into the receptacle at the top of the gauge.

3. Place a drop of coupling fluid on the built-in Probe Zero Plate.

4. Grasp the probe and place it on top of the Probe Zero Plate.

Apply moderate pressure to the top surface of the probe with

your index finger or thumb to stabilize the probe and to keep

the wearface seated flat against the measurement surface.

5. The display will show some thickness value and the Stability Indicator

will have most of its bars illuminated.

6. While keeping the probe on the Probe Zero Plate, press the PROBE ZERO

key. The display will show a value that can be recorded for future use.

7. Remove the probe from the Probe Zero Plate. The gauge is now ready to

perform thickness readings on steel samples.

8. Place a small amount of coupling fluid on the steel surface to be

measured and proceed as explained in step #4 above.

9. The gauge will display the thickness of the steel wall along with the

Stability Indicator showing the relative stability of the reading. If fewer

than five (5) bars are illuminated, the thickness reading displayed is most

likely inaccurate.

Notes

a. When the probe is removed from the sample after a measurement, the

last reading will be retained on the display.

b. Occasionally, a small film of couplant will be drawn out between the

probe and the surface as the probe is removed. When this happens, the

TI-25LT may perform a measurement that is larger or smaller than it

should be. This phenomenon is obvious when one thickness value is

observed while the probe is in contact with the material, and another

value after the probe is removed.

c. The gauge will automatically power off after 5 minutes of non-use.