Tst / tsth, Setup and operation, Specifications – Checkline TST User Manual

Page 4

Series TS Torque Measurement Test Stands

4

SETUP AND OPERATION

1. Mount the test stand to a firm, flat, and level working surface for maximum

safety and accuracy using four 5/16 screws (not included). Use the included

mounting hole drill template to accurately drill the holes. Testing can take

place without securing the test stand in such a manner, however, it is

strongly recommended that the stand be secured, especially for high torque

tests.

2. Install an appropriate sensor and/or indicator onto the slider bracket (an

indicator bracket that mounts onto the test stand column is available sepa-

rately).

3. Install any required attachments, grips, adapters, and other items necessary

for your test sample. Ensure that these items are set up in a secure and safe

manner.

4. Begin the test by turning the hand wheel in either direction. To maintain

smooth operation of the hand wheel, avoid overloads.

The angle dial is adjustable relative to the torque plate. Position the ring by

hand to the desired angle.

The slider’s position is adjustable along the column in order to engage and dis-

engage the test sample. Move the slider lever clockwise to lower the slider’s

position closer to the torque plate. The slider may be locked into position by

tightening the friction brake knob located on the opposite side of the slider.

The travel stops’ positions can also be adjusted. Loosen the knobs, adjust to

the desired positions, and retighten.

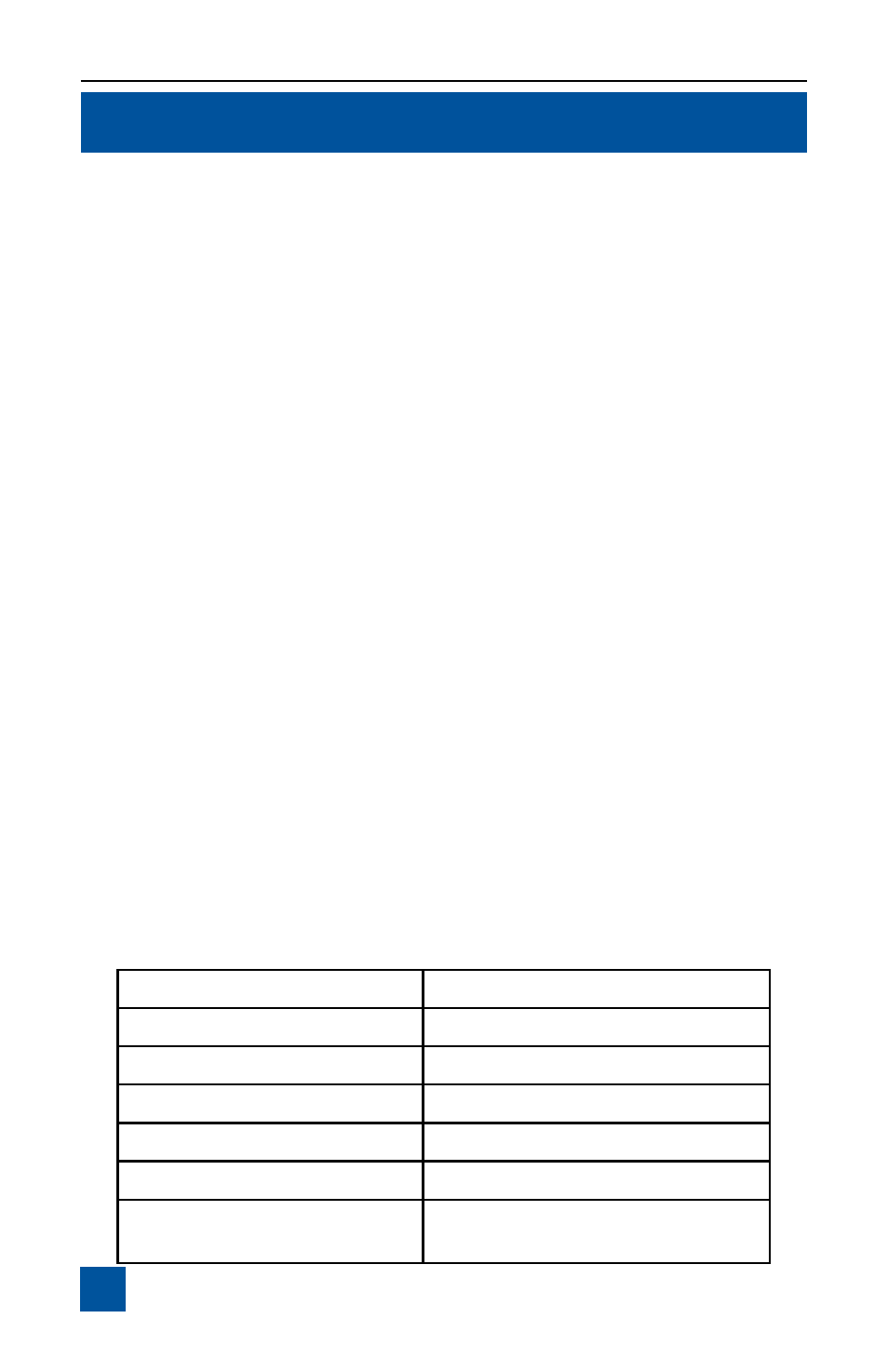

TST / TSTH

Load capacity

100 lbin [11.3 Nm]

Maximum angular travel

No limit

Angular rate

12º/wheel rev

Angle dial resolution

2º

Maximum slider travel

15.5” [394 mm]

Slider travel rate

1.05” [26.6 mm]/lever rev

Weight (test stand only)

TST: 33 lb [15 kg],

TSTH: 27 lb [12.3 kg]

SPECIFICATIONS