Mode 2: elapsed time mode – Checkline DT-5TG User Manual

Page 6

6

Mode 2: Elapsed Time Mode

This mode monitors the time of a continuously variable

process. Say, for example, a baker wants to know the

amount of time needed to bake cookies. By using a

stopwatch, he could measure the amount of time it takes

at a known speed of the conveyor. Or, the baker could

calculate this time by using the distance formula d=vt.

By knowing the calculation time (parameter 4) and rpm of

the sensing gear (parameter 2), the baker can continu-

ously monitor the time as the process varies.

Parameter

Parameter

Parameter

Parameter

Function Setting

Function Setting

Function Setting

Function Setting

Factory

Factory

Factory

Factory

Range

Range

Range

Range

1

Sensing gear

–pulses/ revolution

1

1 – 9999

2

Sensing gear –rpm

200

3

Time units

(=.)

(–.)=sec/sec

(=.)=min/sec

or hr/min

4

Calculation time

02=.00

5

Update time

1

.25, .5, 1, 2, 4, 8, 16

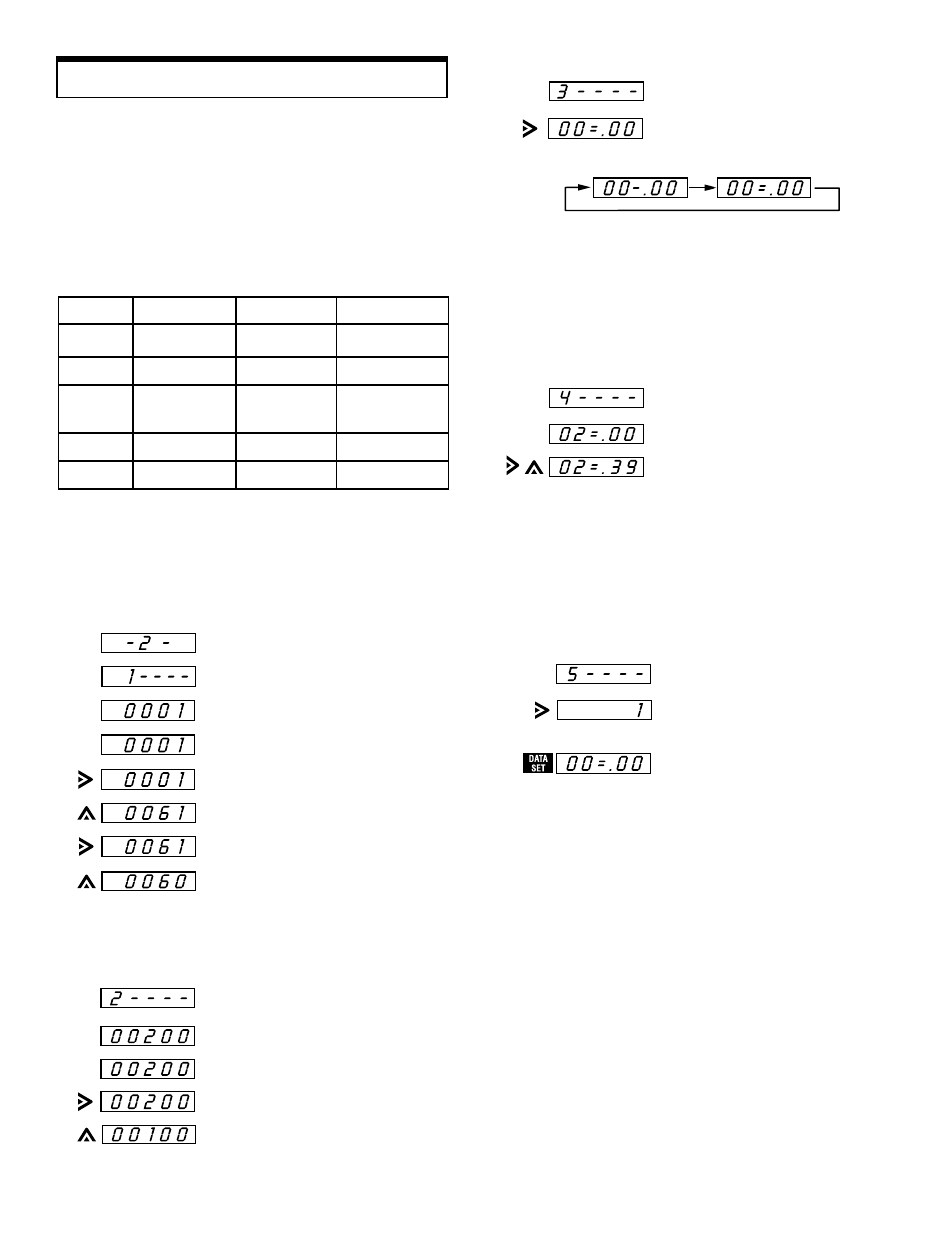

Parameter 1:

Sensing Gear – Pulses per Revolution

This example shows how to change the parameter from 1

to 60 pulses per revolution.

1. Set the unit to mode 2.

2. Press mode key.

3. Press shift key 4 times.

4. Press increment key 6 times.

5. Press shift key.

6. Press increment key 9 times.

Parameter 2: Sensing Gear — RPM

Here's how to change the parameter from 200 to 100 rpm:

1. Press mode key.

2. Press shift key 3 times.

3. Press increment key 9 times.

Parameter 5: Update Time

1. Press mode key.

2. Press shift key to select update

times.

The parameter settings are now

complete. Press data set key to start

elapsed time counter.

Parameter 3: Time Units

1. Press mode key.

2. Press shift key to select units.

Unit symbols:

=. hour/minute or minute/second

–. second/second

Parameter 4: Calculation Time

1. Press mode key.

2. Press shift and increment keys to

program time calculated.

If the display shows

--=.E9

--=.E9

--=.E9

--=.E9

--=.E9, an entry error has been

made. Reprogram the unit using the shift and increment

keys.