7102-instl_081120.2, Sheet2, Drawing view1 – California Faucets Widespread Lavatory Faucet User Manual

Page 2: Drawing view2, Drawing view4, Drawing view5, Drawing view13

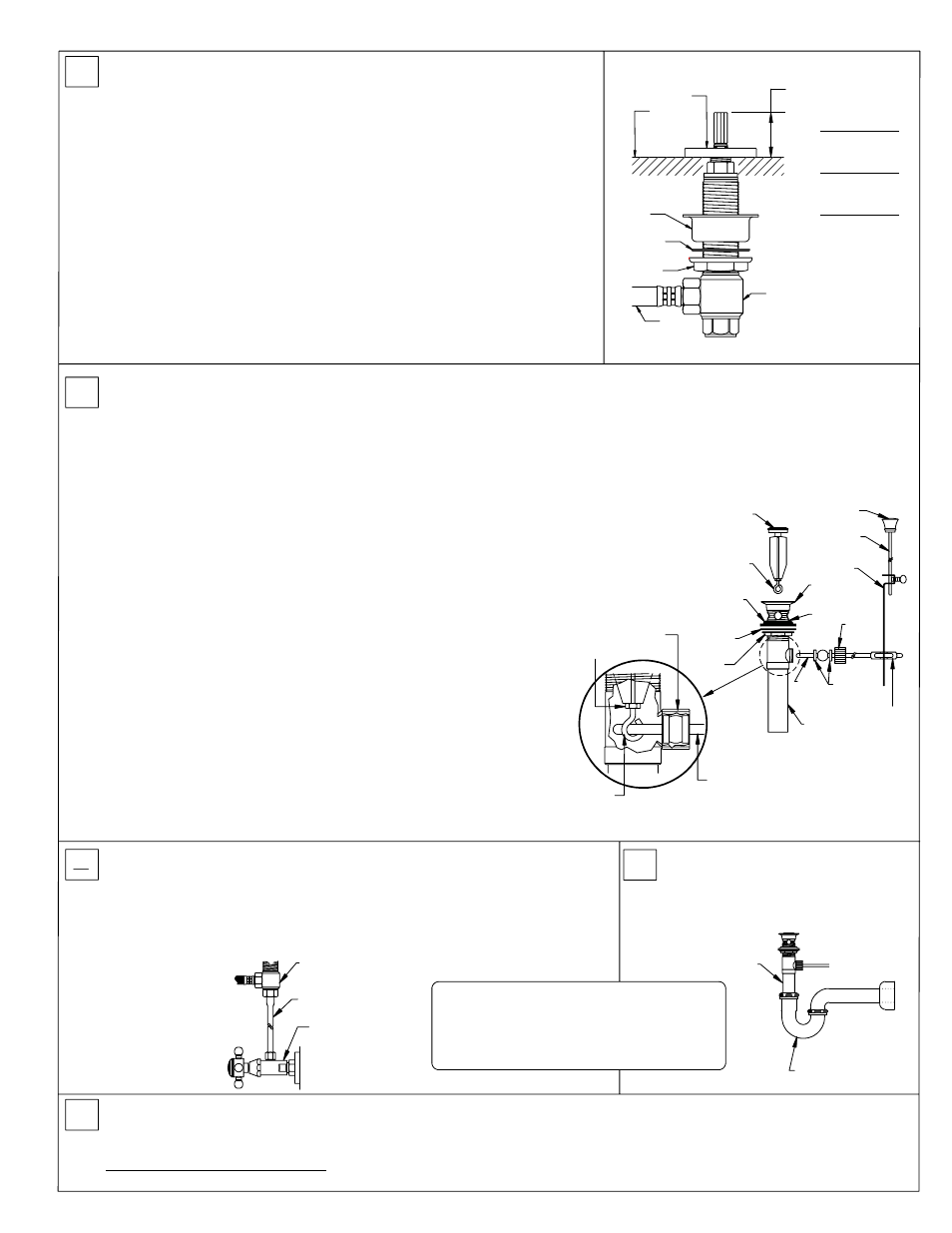

"A"

Sink/

Countertop

Escutcheon

Spacer

Cup

Fiber

Washer

Bottom

Nut

Flex

Line

Valve

Lift Knob

Hole Rod

Strap

Nut

Ball

Rod

Cone

Washers

Fiber

Washers

Drain

Tailpiece

Rubber

Washer

Drain

Collar

Stopper

Drain

Rim

Adjustable

Eye-Screw

Nut

Brass

Nut

Connect faucet to water supply

(See Fig. 6)

:

IMPORTANT: Flush supply lines of all debris prior to connecting to lavatory

valve bodies. Debris remaining in the line will damage valve bodies and

cause leaking. Failure to flush the lines could result in voiding the warranty.

5

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Adjustable

Eye-Screw

Ball

Rod

Lift

Rod

Drain

Tailpiece

"P" Trap

(not supplied)

Angle Stop

(not supplied)

Valve

Body

Supply Riser

(not supplied)

2

Spring

Clip

Lock

Nut

-Connect supply risers from the angle stops.

NOTE:

P-trap, angle stops, and supply risers

are not supplied. We recommend genuine

Cal-Trim parts available at your authorized

California Faucets dealer.

P2

4

3

Install pop-up assembly

(See Fig 4 & 5)

:

7102-INSTL_081120

NOTE: Hot & cold valves are labeled: RED = hot & BLUE = cold.

-Remove top nut and discard.

-Turn bottom nut with fiber washer down the valve until it stops.

-Place spacer cup onto valve oriented correctly as shown.

-Insert valve through hole from below.

-Attach and thread escutcheon onto threads below stem and

adjust valve to scheduled height "A".

-Place handle onto stem allowing minimal gap between escutcheon and

handle. Tighten setscrews with Allen key provided.

-Align handle in desired position and tighten the bottom nut to secure valve.

NOTE: Align square escutcheon on 7202 Series prior to securing valve.

-Attach flex lines between valves and spout tee.

-Flex lines shall be handtightened, then tighten 1/4 to 1/2 turn with wrench.

(wrench not supplied).

-Separate drain collar from pop-up assembly.

-Apply silicon caulking to underside of drain collar.

NOTE:

Do not use

"Plumbers Putty" or any oil based sealants! Use of anything other than

silicon caulking will VOID the finish warranty.

-Insert drain body from underside through sink. Slowly screw on drain

collar, align with ball rod hole facing back wall, then gently pull down into

sink and firmly tighten brass nut from below.

-Remove tailpiece from drain body and apply teflon tape, approx. 3 to

5 wraps around threads and reinstall into bottom of drain body.

-Insert stopper in collar and hold with eye-screw hole facing back.

If necessary, adjust stopper eye-screw height by loosening lock nut and

rotating counter-clockwise. Tighten lock nut

(See Fig. 4).

-Remove spring clip from ball rod.

-Remove nut and cone washers and slide onto end of ball rod.

-Insert ball rod into drain body below so short end of ball rod end fits

in stopper eye-screw hole. Snug ball rod nut (do not over tighten).

Ball rod must move up & down freely

(See Fig. 4).

-Insert lift rod through top of spout and then through hole rod strap

underneath sink. Tighten thumb-screw of hole rod strap

against lift rod and connect to ball rod by gently pinching locking

spring clip and sliding one side of spring clip onto ball rod.

-Insert hole strap onto ball rod, then pinch spring clip together to fit

on ball rod.

Fig. 3

7102 Series

"A" = 1"

7202 Series

"A" = 3/4"

7302 Series

"A" = 1"

Install "P" trap

(See Fig. 7)

:

-Connect your waste "P" trap

to the drain tailpiece.

6

Turn on Water Supply:

Operate hot and cold valves: Inspect all joints and fittings for leaks.

NOTE: Due to sediment in the water it may be necessary on occasion to remove the aerator/flow restrictor and clean the

screen with a soft bristle toothbrush.

IMPORTANT CLEANING NOTICE: Please refer to Finish Care Instructions for complete cleaning information. Wipe frequently

with a soft, damp cloth.

Never use acids, harsh abrasives or detergents.

Install valve bodies

(See Fig. 1 & 3)

: