1 bead productivity and cell density – BUCHI Encapsulator B-390 User Manual

Page 43

6 Operation

43

B-390

Operation Manual, Version C

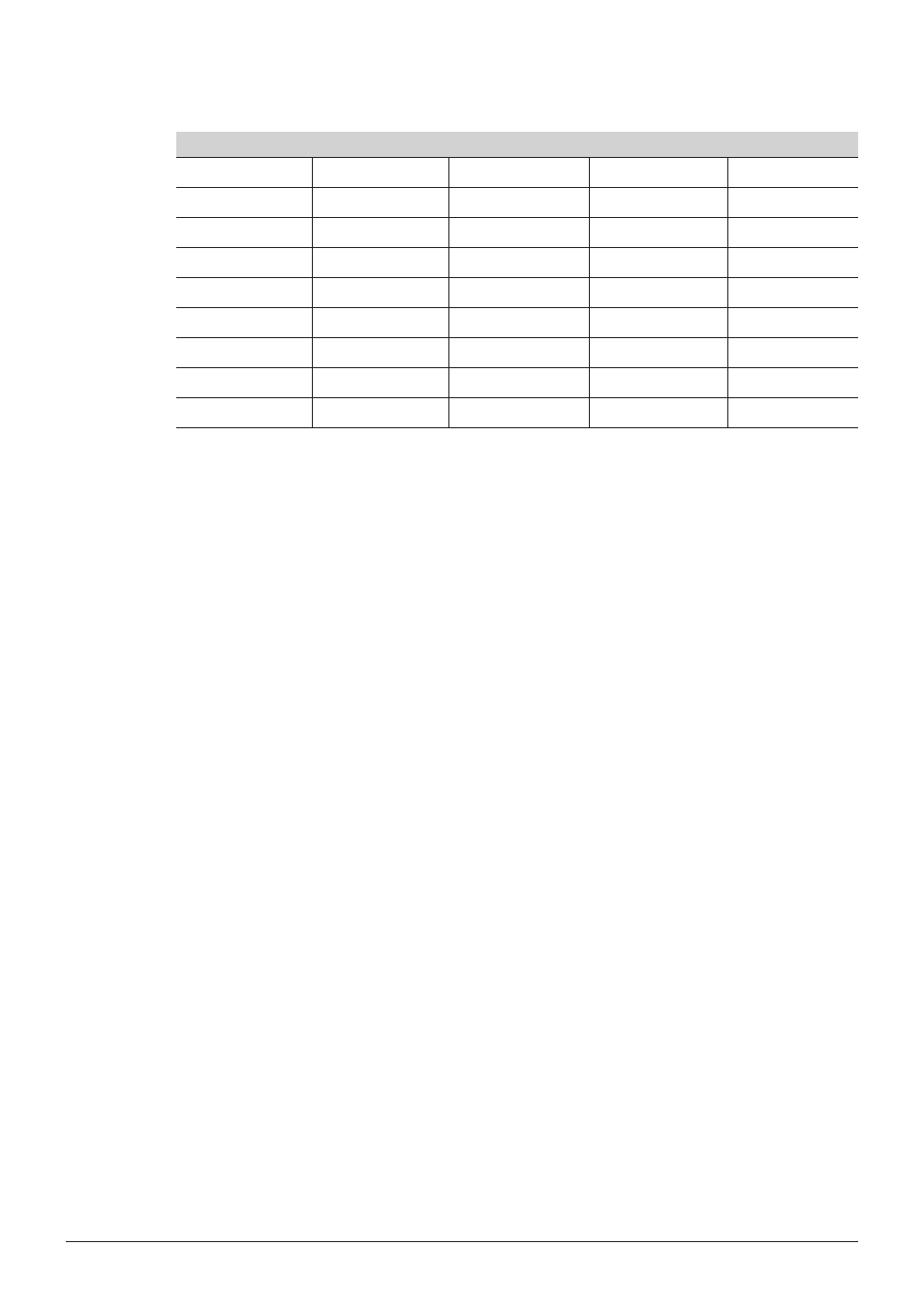

Table 6-4: Optimal working conditions for the Encapsulator determined with alginate solution

Nozzle diameter [

µm] Flow rate * [mL/min] Frequency interval **

Amplitude

Air pressure [bar]

1.0 mm

30 to 40

40 to 220 Hz

2 to 6

0.3 to 0.6

750

µm

19 to 25

40 to 300 Hz

2 to 5

0.3 to 0.5

450

µm

9 to 14

150 to 450 Hz

2 to 5

0.3 to 0.5

300

µm

5.5 to 7

400 to 800 Hz

1 to 3

0.3 to 0.5

200

µm

3.5 to 4.5

600 to 1200 Hz

1 to 3

0.4 to 0.6

150

µm

2.3 to 2.8

800 to 1800 Hz

1 to 3

0.4 to 0.6

120

µm

1.5 to 1.8

1000 to 2500 Hz

1 to 4

0.5 to 0.7

80

µm

1.1 to 1.3

1300 to 3000 Hz

1 to 4

0.5 to 0.7

* Tested with 2 % low viscosity grade alginate solution for 750 µm and 1.0 mm nozzle, with 1.5 %

alginate solution for the 150 to 500 µm nozzle and with 1.2 % alginate solution for the 80 and 120 µm

nozzles.

**Upper values with application of high voltage.

NOTE

For solutions with a viscosity different from the tested one, it can be said that:

• the higher the viscosity the higher the minimal jet velocity

• the higher the viscosity the higher the working flow rate

• the higher the viscosity the lower the optimal frequency

• the higher the viscosity the larger the beads

6 .7 .1

Bead productivity and cell density

Figures 6-6 and 6-7 indicate the amount of beads formed from 1 mL of liquid. About 30,000 beads

with a diameter of 0.4 mm will be formed, but only 2,000 with a diameter of 1 mm.

Figures 6-8 and 6-9 indicate the number of cells which are encapsulated in one bead for a given

cell density and bead diameter. These figures may help you select the appropriate cell density in the

immobilization mixture. For example, if the immobilization mixture contains 1×10

6

cells per mL, then

about 33 cells are, on average, in each 0.4 mm bead, but, about 520 cells will be in each 1 mm bead.