2 installing the encapsulator b-390, Installing the encapsulator b-390 – BUCHI Encapsulator B-390 User Manual

Page 20

5 Putting into operation

20

B-390

Operation Manual, Version C

5 .2

Installing the Encapsulator B-390

Place the instrument on the lab bench with convenient access to an AC electrical outlet and to

compressed air. Place the instrument in a way that disconnection of the electric supply plug is

possible at all times.

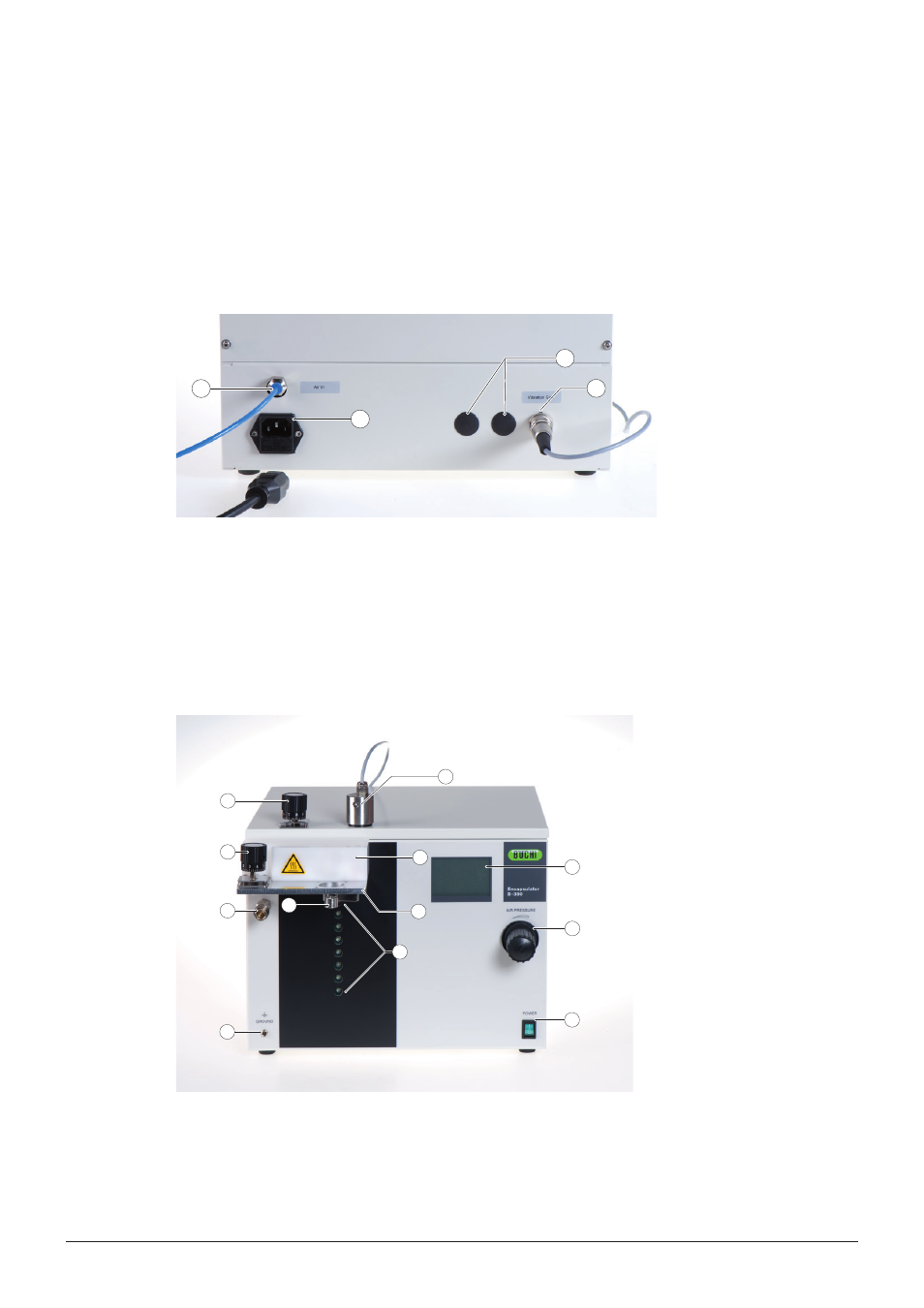

Connect the external air/gas supply (=air inlet) and the vibration unit as shown in figure 5-1.

4

1

2

3

a Air inlet (blue tube 2.6×4.0 mm)

Electric supply socket with inte-

grated fuse

Socket for vibration unit

Optional socket

Figure 5-1: Rear view of the control unit

All controlling systems for bead production are incorporated in the control unit. Vibration frequency,

light intensity, electrostatic dispersion and heating, are controlled on the touch screen. Air pressure

is regulated with the pressure regulating valve. The pressure is electronically indicated on the touch

screen. The pumping rate of the polymer mixture is controlled with the liquid flow regulating valve.

The integrated stroboscope lamp allows real time jet breakup control. The main switch is on the front

panel. The bead producing unit is attached to the carrier plate with two screws (M3×25).

9

6

1

10

7

11

5

3

2

4

12

8

a Vibration unit

Touch screen

Pressure regulating valve

Mains switch

Plug for grounding wire

Air outlet

Liquid flow regulating valve

Liquid flow regulating valve

Heating block

Carrier plate

k Electrode

Stroboscope lamp

Figure 5-2: Front view of the control unit