8 troubleshooting, 1 malfunctions and their remedy, Malfunctions and their remedy – BUCHI Vacuum Controller V-855 User Manual

Page 46: 8troubleshooting, 8 .1 malfunctions and their remedy

8 Troubleshooting

46

V-850/855 Operation Manual, Version E

8

Troubleshooting

This chapter helps to resume operation after a minor problem has occurred with the instrument. It lists

possible occurrences, their probable cause and suggests how to remedy the problem.

The troubleshooting table below lists possible malfunctions and errors of the instrument. The operator

is enabled to correct some of those problems or errors by him/herself. For this, appropriate corrective

measures are listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical

engineer who has access to the official service manuals. In this case, please refer to your local BUCHI

customer service agent.

8 .1

Malfunctions and their remedy

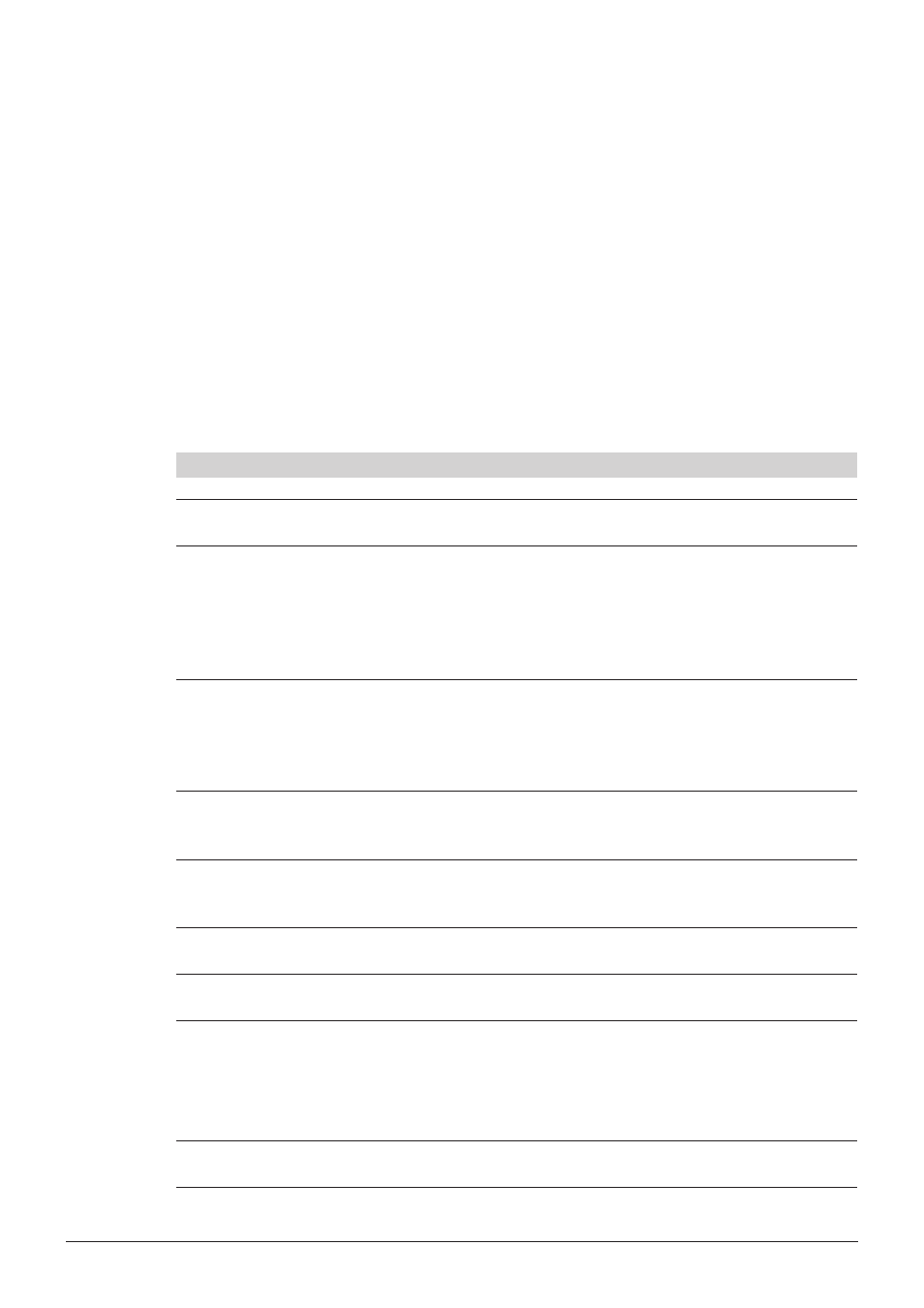

Malfunction and their remedy

Malfunction

Possible cause

Corrective measure

No display

Instrument has no current

Switch instrument on, check mains

connectins

Frequent switching of valve or pump

System is leaky

Hysteresis is too small

Control all sealing points (tubes and

their connections)

Choose a larger hysteresis (if

the end-vacuum is higher than

700 mbar, set the instrument to

automatic hysteresis

Valve does not switch

Valve does not close

Valve coil is dirty

Valve cable is not plugged in

Valve is not adjusted, contact the

BUCHI customer service for assis-

tance

No vacuum

Tubing or cabling incorrect

Correct the tubing or cabling by

referring to the corresponding

chapters

Vacuum is not reached

Back evaporation at the Rotavapor

Water pressure to water jet pump is

too low

Empty the receiving flask and

completely open the water tap

Dry the pump diaphragm

Auto distillation has “abated”

Manually decrease the pressure until the distillation starts again, then return

to the automatic function, if desired

EasyVac distillation “abated”

Manually decrease the pressure until the distillation starts. The distillation

stops automatically

Distillation ended although not dried

out completely

- Back evaporation from the receiving flask is too strong (especially for

solvent mixtures), drain receiving flask and restart the distillation

- Malfunction in distillation process is not exactly defined (e.g., sudden

cooling, heat flow is too low, etc. Decrease the pressure manually until the

distillation starts again, then return to the automatic function, if desired

Too much remaining liquid after auto

distillation

Manually decrease the product pressure to distill the remaining liquid