Brookfield Thermosel User Manual

Page 10

Brookfield Engineering Laboratories, Inc.

Page 10

Manual No. M/94-204-I0612

I.5 General

The operator should become familiar with the alignment procedure so that the system can be safely

aligned and operated at elevated temperatures.

The system is designed to operate in the temperature range from 40°C (104°F) to a maximum of

300°C (572°F). Control of test sample temperature is possible in this range with accuracy as follows:

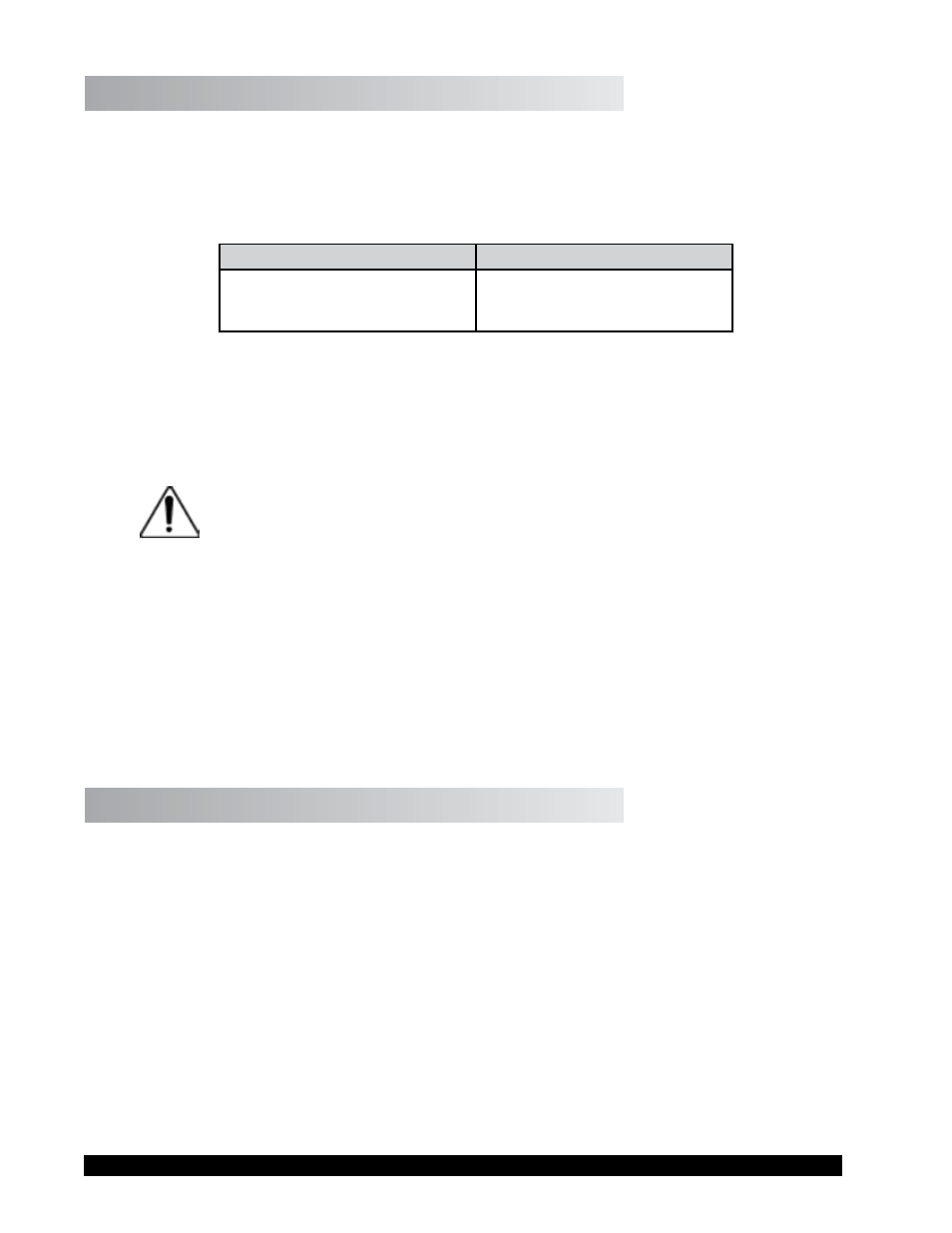

Temperature Range

Temperature Accuracy

40°C to +150°C

+150°C to +300°C

±1.0°C

±2.0°C

NOTE: The lower limit of control is approximately 40°C (104°F). The upper limit of precise

control is 300°C (572°F). This is determined not by the controller-heat element

capabilities, but by design of the spindle, sample chamber, thermo-container, and

the proximity of the viscometer to the thermo-container.

USE OF ThE SySTEm AbOvE 300°C COUlD rESUlT IN DAmAgE TO

ThE ThErmO-CONTAINEr AND TO ThE vISCOmETEr.

The controller will bring the thermo-container to elevated set point temperature in approxi mately

30 minutes. However, lowering the temperature from the elevated set point can be quite time

consuming. Approximately four hours is required for the thermo-container to cool from 260°C

(500°F) to 37°C (100°F). Using the optional cooling plug (HT-26Y) this temperature reduction can

be accomplished in about 20 minutes. Familiarization with the temperature controller instructions

should be made at this time.

Refer to Appendix A for viscosity range data, spindle factors (for use with Dial Reading Viscometers),

and test volume sample size. This information is to be used when obtaining viscosity measurements.

I.6 Viscosity Measurements

Samples That Are Liquid At Ambient Temperature

With the instrumentation assembled and familiarization completed, the following steps are

recommended for taking viscosity measurements of samples which are liquid at ambient temperature:

1. Remove the insulating cap; unthread the coupling nut and remove the spindle.

2. Raise the viscometer to the highest level on the stand.

3. Remove the sample chamber (HT-2 or HT-2D) using the extracting tool (HT-59 or HT-116

respectively) and place it in the sample chamber holder (HT-54).

4. Using a syringe, graduated cylinder, or other suitable measuring device, pour into the sample

chamber the volume of liquid sample specified on the range table in Appendix A.