Brookfield Cooler, TC-351 User Manual

Page 6

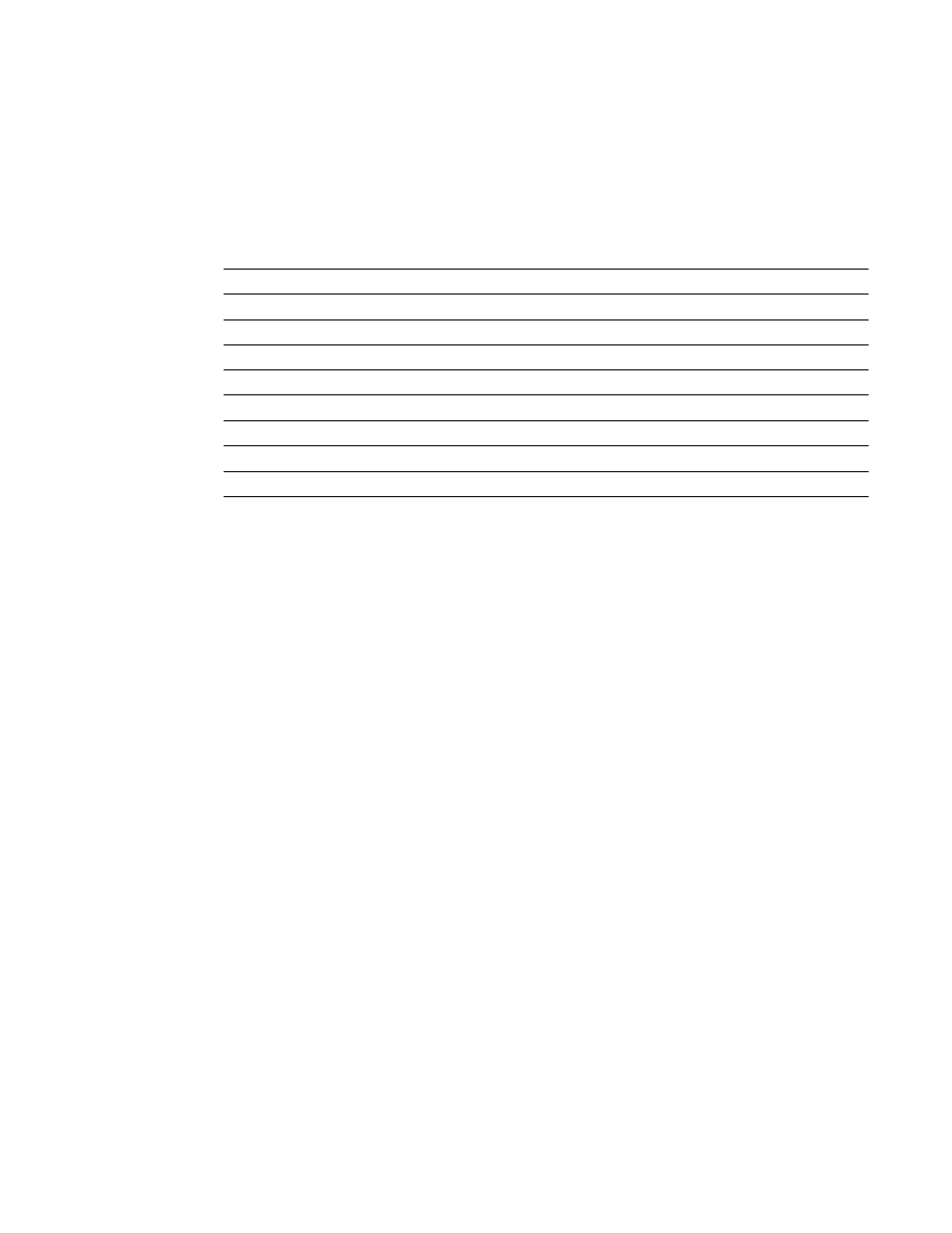

Section 4. Troubleshooting

4.1

Problem / Solution Chart

The following chart outlines a few problems that may arise. The solutions are listed in order of priority.

Problem

Solution

Does not run

12, 4

No cooling

6, 7, 1, 2, 4, 10, 8

Insufficient cooling power

3, 5, 7, 6, 10, 2, 4, 11, 8

Runs 5 minutes, compressor shakes or stalls, restarts 5 minutes later

5, 2, 1, 8, 4

Compressor will not start. Clicks about every 30 seconds

1, 2, 4, 8

Gradual loss of cooling

3, 10, 11

Condenser fan not running or making loud noises

4

Fluid gets too cold

9

Stops cooling when fluid is cold

6, 7, 5, 10, 11

Solutions

1.

Compressor may be cycling on overload. Shut off power for at least 10 min. Then restart.

2.

Improper line voltage, frequency, or both. Insufficient power supply during starting. Check

voltage at power source during start cycle. Voltage must be within 10% of rated voltage. Avoid

extension cords which can cause voltage drops.

3.

See Section 3.1, Required Maintenance. Check for air flow exiting the back of unit. Air vents

should not be closer than four inches from wall. Unit should not be placed in cabinet. Place

where exiting warm air will not return to the intake, or near warm air from other sources. High room

temperature reduces cooler's capability.

4.

Unplug unit, remove cover. Check that condenser fan blade moves freely. If not, check fan

bracket or blade for misalignment.

5.

Fluid too hot for the cooler to continuously cool. Check specifications for heat removal. At less

than 0°C, heat loss to the room may be excessive. Containers and tubing should be insulated

where condensation or frost occur. High power pumps can introduce excessive heating.

6.

Fluid viscosity too high or freezing at desired temperature. Unit may freeze internally and block

the flow. Freezing point of fluid should be 10° to 20°c lower than desired temperature. See

Section 2.3, Choice of Fluids

7.

Insufficient fluid flow rate to provide cooling. Quick connectors or tubing less than 3/8 in, diameter

may restrict flow. Flow should be 3 to 15 lpm.

8.

Compressor may be overcharged with refrigerant. If compressor does not start and all other

possibilities checked, compressor may be defective.

9.

Coolers are intended to connect to other systems that pump, heat and control temperature.

coolers do not have thermostats and will only reduce temperature to as low as they can go.

10 Possible refrigerant leak. A licensed refrigeration service person should recover refrigerant, find &

repair leak, evacuate and recharge.

11. After many years, compressor valves may produce high pitch buzzing sound.

12. Check power. Unit's power switch should be illuminated.

7