Brookfield Cooler, TC-351 User Manual

Page 5

6

APPLICATION NOTES

At fluid's low temperature extreme:

1.

Presence of ice or slush adversely affects temperature stability.

2.

Viscosity above 10 centistokes adversely affects temperature uniformity.

3.

High fluid viscosity and high speed pumping generates heat in the fluid.

2.5

Operation

1.

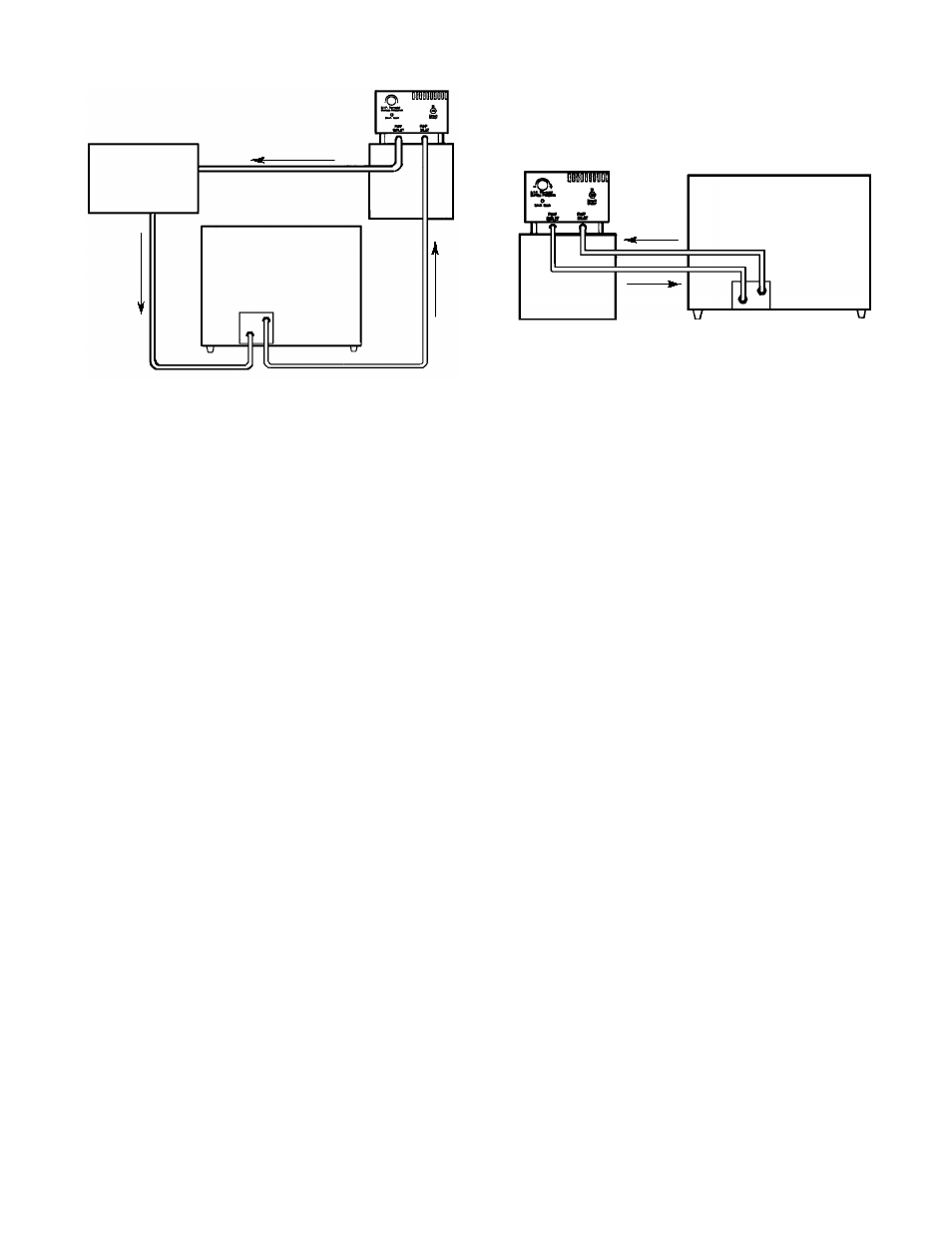

Depending on your application, connect the unit as shown in Figure A or B. When connecting

tubing to the fittings at the back of the unit, use the lower fitting as the inlet for the circulated fluid.

2.

First, fill the circulator with fluid and power on circulator.

3.

Set the circulator's temperature. After the circulator's temperature stabilizes, turn the cooler on.

APPLICATION NOTES

1.

Your application may require fluid to be pumped through one or more external systems as in Fig. A.

The limitations are: the pump capacity; the unit's cooling capacity; and it must be a closed system.

2.

The circulator must have adequate heating capacity in order to overcome the cooling effect of the

cooler. If the heating is insufficient, the fluid will continue to be cooled below the set temperature

and lack of control will result.

3.

Fluid may need to be added to the circulator reservoir to compensate for fluid pumped into tubing,

the cooler and the external device.

Section 3. Maintenance

3.1

Required Maintenance

The refrigeration condenser fins are located just behind the side grill holes. Dust that accumulates

reduces the amount of cooling power available. The dust should be blown out periodically with

compressed air. All other items are permanently lubricated and need no attention.

Device to be

operated at

controlled

temperature

Input

Input

Fig. A - Interconnection of the flow-through cooler,

circulator and device at a controlled temperature

Fig. B - Interconnection of the flow-through cooler and

circulator when tempering samples in the circulator

Output

Output

Circulator

Circulator

Flow-Through Cooler

Flow-Through Cooler