STIEBEL ELTRON SOL 25 PLUS User Manual

Page 31

WWW.STIEBEL-ELTRON-USA.COM

SOL 25 PLUS |

31

EN

G

L

IS

H

been premixed and require no further treatment. Never mix water

with the heat transfer fluid, otherwise the essential characteristics

and corrosion protection can no longer be guaranteed. The system

must not be topped off with water.

Follow these steps to complete the final charging and venting

(purging of air) of the system:

1. Energize the pump station to activate the electric pump to

circulate the solar medium through the system.

2. Open the manual air vent valves on the SOL 27 Premium inlet

and outlet connectors and open the ball valve for the flow meter.

3. To purge air from the system, the size of the air bubbles can

be reduced (as the system loop pressure increases), by slowly

constricting the return flow to the drain bucket via partially closing

the lower drain & fill valve while the pump is operating. Also

open the bleed screw on the circulator pump.

4. Continue purging the system until no more bubbles are

expelled from the drain hose. Allow system pressure to build

up to approx. 20-44 psi. This process usually takes 20-30 minutes.

Continue looking for leaks.

5. Tighten the safety-leak-cap valve fully and then

back off 1/4-turn.

6. Close the bottom fill & drain valve after completing this

ventilation step, but before shutting off the pump.

7. Keep the circulator pump running and then close the top fill &

drain valve.

8. Open the air vent valve at the highest point, until only solar

medium is expelled.

9. Shut off the circulating pump.

10. Open the valve to the expansion tank to connect it to the solar

loop. The system pressure will drop slightly.

11. Use the charging pump to raise the system pressure (in a cool

state) to its operating pressure of 50 psi (50 to 58 psi).

12. Use a permanent marker to record the pressure, date, and

time on the expansion tank.

13. It is further recommended that the installer measure and

record the glycol/water mixture using a refractometer or

hydrometer. It is critically important that the mixture be correct

before turning the system over to the final customer.

14. Set the red dial on the pressure gauge to the expansion tank’s

precharge pressure. This should be the lowest pressure that the

system ever reaches in the coldest day of operation.

15. Let the solar heating system rest overnight and vent again in

the morning, via the manual air vent valves, before solar radiation

warms the collectors.

16. Turn check valves in the pumping station to their normal

position to allow one-way flow.

17. Make sure the controller and pumping station are energized

and that the proper settings for the controller have been entered.

18. Cover both fill & drain valves with the caps supplied and tool

tighten (not hand removable).

19. If the system does not start automatically, there may still be

air in the system. Repeat the venting process, if required.

and possible burns from escaping steam. If the sun shines during

start-up, cover the collectors or wait until there is some shade.

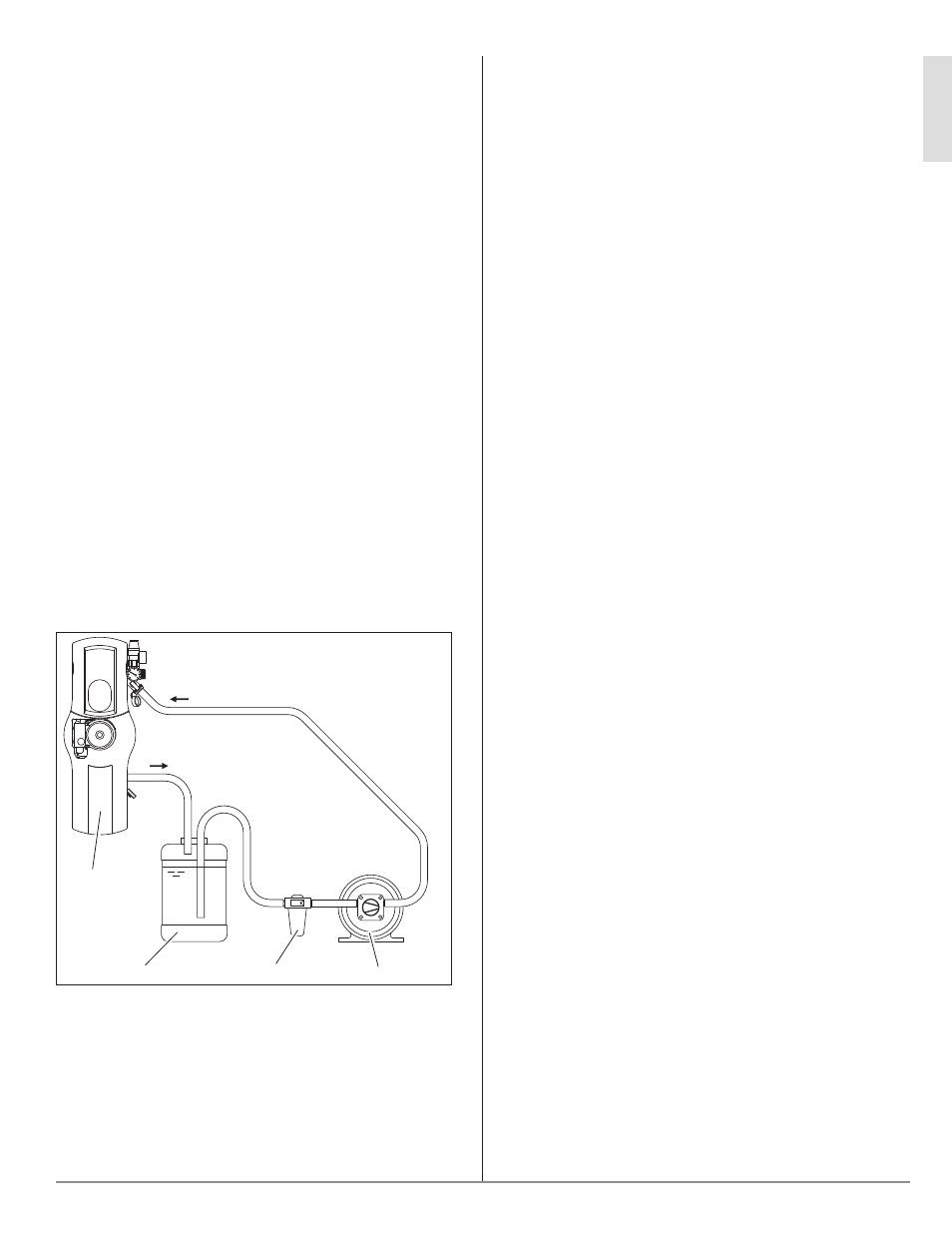

The following procedure makes use of a charging pump, screen

filter, and large pail or trough to circulate fluid through the system.

The sump can have a coarse-mesh screen to prevent large particles

from entering the pump. The outlet of the pump can be fitted with

5-micron sediment filter. The intake sump should be set near the

bottom of the pail.

1. Connect the charging pump’s outlet to the to fill & drain valve

in the pumping station.

2. Connect a hose to the boiler drain at the bottom of the loop

(bottom fill & drain valve), at the outlet side of the storage tank’s

heat exchanger.

3. Use a clean, dry pail or catch basin. During this process, hold

the drain hose firmly to the container or clamp them. Make sure

you have sufficient Dowfrost medium (propylene glycol mixture) to

fill the entire system’s volume, plus extra for purging.

4. Keep all other vents and valves closed during the flushing

operation.

5. Close the flow meter adjusting screw at the pump assembly

(horizontal position).

6. Start charging the system and observe the loop fluid draining

back into the pail. Make sure that the fluid level in the container

always remains higher than the intake hose.

7. The flushing process should continue until the fluid draining

back appears clean and free of contaminants. The screens/filters

may require cleaning during this process.

8. When the system is fully flushed, proceed to the final charging

phase, described below.

1

Solar-Kompaktinstallation

2

Wärmeträgerflüssigkeit

3

Füllpumpe

4

Filter

26_05_01_0515

2

1

3

4

1 Solar compact installation

2 Heat transfer medium

3 Filter

4 Fill pump

8.4 Final Charging and Venting The System

The solar heating system must be filled exclusively with the

premixed propylene glycol heat transfer medium. The bottles have