Nozzle assembly maintenance – Beckett ADC 24Vdc User Manual

Page 5

5

24 Vdc ADC Burner Manual

Section: Nozzle Assembly Maintenance

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates could

result in impaired combustion, under-

fi ring, over-fi ring, sooting, puff-back of

hot gases, smoke and potential fi re or

asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph),

spray angle and pattern specifi ed by the appliance

manufacturer.

Follow the appliance manufacturer’s specifi cations for the

required pump outlet pressure for the nozzle, since this

affects the fl ow rate.

y

Nozzle manufacturers calibrate nozzle fl ow rates at

100 psig.

y

When pump pressures are higher than 100 psig, the

actual nozzle fl ow rate will be greater than the gph

stamped on the nozzle body. (Example: A 1.00 gph

nozzle at 140 psig = 1.18 gph)

Securely tighten the nozzle (90 torque inch pounds). For typical

nozzle fl ow rates at various pressures refer to Table 3.

Use care when removing or

installing an oil nozzle

A damaged nozzle could cause impaired combustion,

sooting, puffback of hot gases, oil leakage and

potential fi re or asphyxiation hazards.

y

Inspect the nozzle adapter to insure that the sealing

surface is not grooved or scratched.

y

To insure that the nozzle functions properly, check the

orifi ce and strainer for dirt, scratches or other damage

before installation.

y

Do NOT attempt to install or remove a nozzle without

securing the adapter to prevent seriously damaging

the alignment.

y

Use care when handling the nozzle line assembly

to prevent changing the electrode tip settings or

damaging the ceramic electrode insulators.

y

Ensure that the electrode settings match the values

shown in Figure 2.

D. Exhausting Hazardous Fumes

See warning on this page. Also be conscious of any fumes

produced by the materials that are being heated. Always

ensure adequate ventilation to exhaust all fumes.

E. Low Firing Rate Baffl e.

The low fi ring rate baffl e (See LFRB in Replacement Parts)

reduces the air fl ow and pressure. The LFRB is sometimes

used for fi ring rates under 1.00 gph as listed in Table 1.

Refer to the equipment manufacturer’s instructions. Do

not omit the LFRB when specifi ed. Omitting the baffl e

when specifi ed or installing the baffl e when not specifi ed

could result in poor burner performance.

Nozzle Assembly

Maintenance

A. Replace the Burner Nozzle.

1. If applicable, remove the plastic plug protecting the

nozzle adapter threads.

2. Place a 3/4” open-end wrench on the nozzle adapter.

Insert the nozzle into the adapter and fi nger tighten.

Finish tightening with a 5/8” open-end wrench.

3. If the nozzle is already installed, remove the nozzle

line assembly to verify that the nozzle size and spray

pattern are correct for the application (per equipment

manufacturer’s information). Verify that the electrode

tip settings comply with Figure 2.

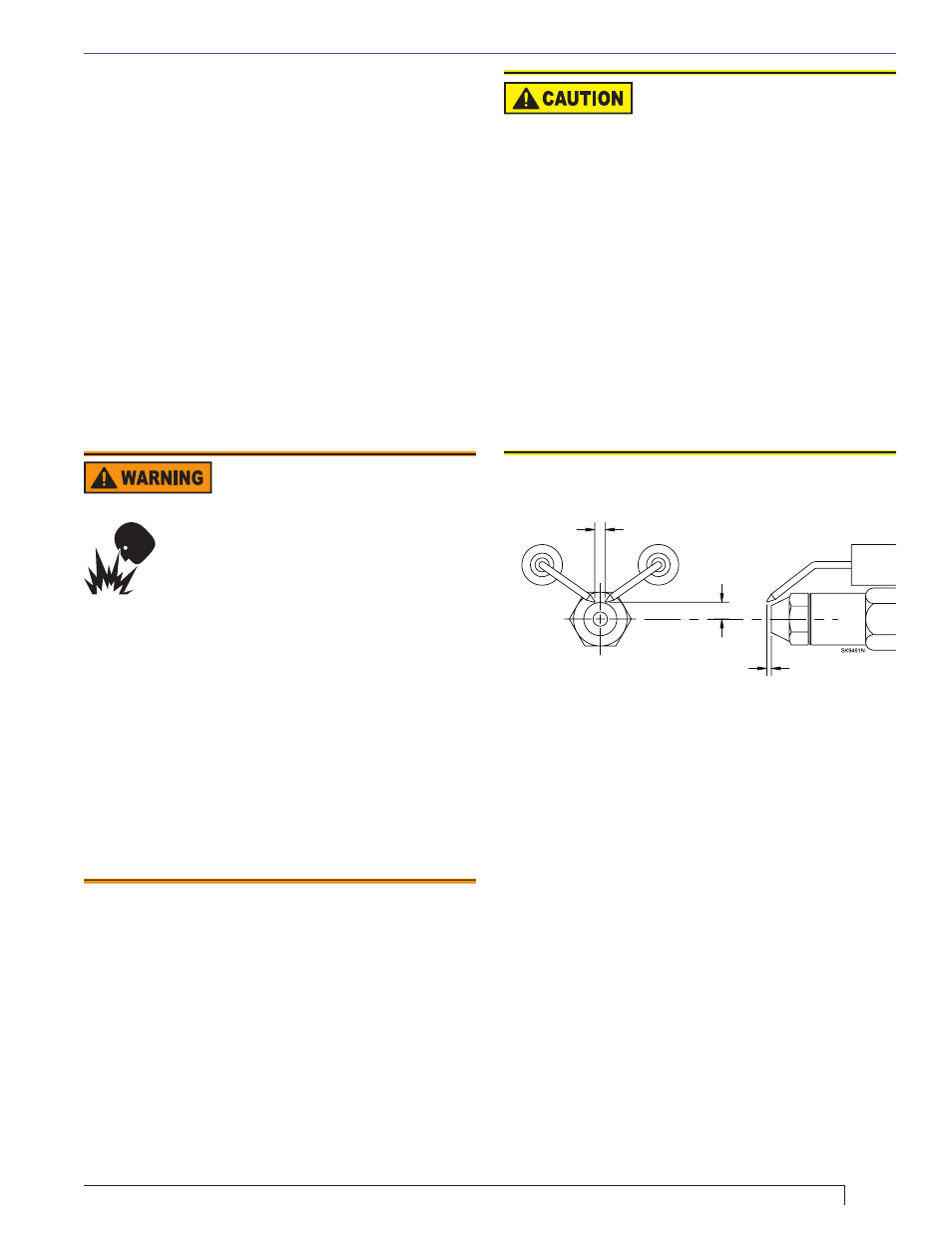

B. Check/Adjust Electrodes

Check the electrode tip settings. Adjust if necessary

to comply with the dimensions shown in Figure 2. To

adjust, loosen the electrode clamp screw and slide/rotate

electrodes as necessary. Securely tighten the clamp

screw when fi nished.

C. Igniter Maintenance

The igniter assembly does not require any adjustments

beyond making sure the springs and the burner electrode

rods make solid contact when the igniter is in the closed

position. The sealing surfaces of the gaskets should be

checked and replaced at the fi rst signs of any damage or

deterioration. Clean any dirt or residue from the porcelain

bushings, springs, and baseplate.

The simplest way to check igniter operation is by supplying

voltage to the input and checking to see whether an arc

is produced. Check by either looking or listening to see if

there is an arc across the electrodes while the burner is

running and the igniter is energized.

Figure 2. Electrode Tip Setting

1/4” ABOVE

CENTER

5/32” GAP

1/8” NOZZLE-TO-TIP

SPACING