Troubleshooting – Beckett ADC 24Vdc User Manual

Page 13

13

24 Vdc ADC Burner Manual

Troubleshooting

Oil burners that are designed for use on road maintenance

equipment are built to take temperature extremes,

vibration, and rough handling. When performing the

following troubleshooting steps, we assume that the oil

burner motor and ignition transformer operate continuously

and the oil solenoid valve, which controls oil fl ow, is cycled

by the equipment controls. We also assume that there is

power to the burner and fuel in the tank.

In addition to typical mechanics tools, it is recommended

to have the following equipment on hand.

○

Meter capable of measuring volts, ohms and amps,

○

ignition transformer tester,

○

smoke pump tester,

○

combustion analyzer, and

○

0 to 200 psi pressure gauge.

See Table 4 on following page for troubleshooting steps.

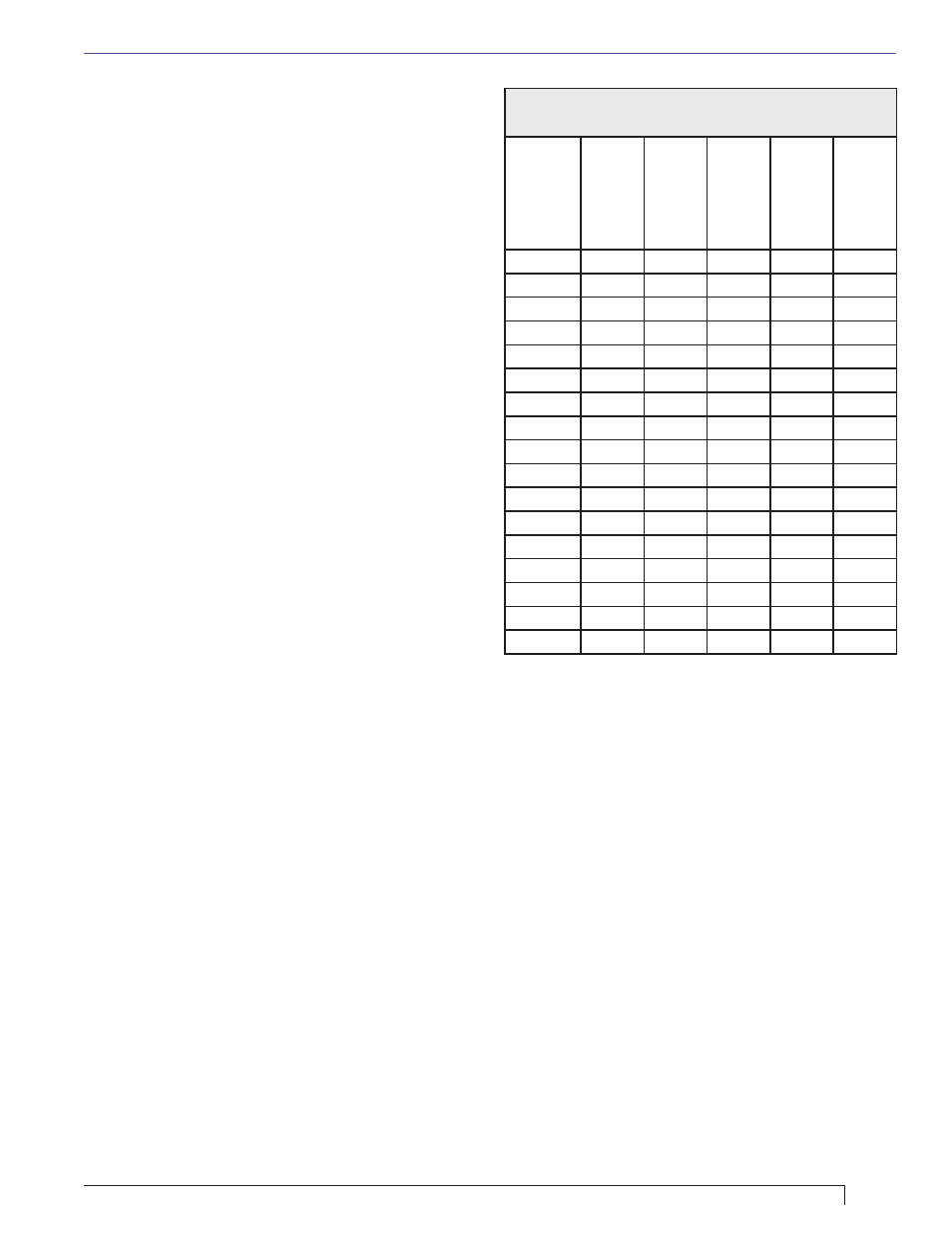

Table 3. Nozzle Flow Rate by Size

Nozzle fl ow rate U. S. gallons per hour of No. 2 fuel oil

when pump pressure (psig) is:

Nozzle

Size

(rated

at 100

psig)

125

psi

140

psi

150

psi

175

psi

200

psi

0.40

0.45

0.47

0.49

0.53

0.56

0.50

0.56

0.59

0.61

0.66

0.71

0.60

0.67

0.71

0.74

0.79

0.85

0.65

0.73

0.77

0.80

0.86

0.92

0.75

0.84

0.89

0.92

0.99

1.06

0.85

0.95

1.01

1.04

1.13

1.20

0.90

1.01

1.07

1.10

1.19

1.27

1.00

1.12

1.18

1.23

1.32

1.41

1.10

1.23

1.30

1.35

1.46

1.56

1.20

1.34

1.42

1.47

1.59

1.70

1.25

1.39

1.48

1.53

1.65

1.77

1.35

1.51

1.60

1.65

1.79

1.91

1.50

1.68

1.77

1.84

1.98

2.12

1.65

1.84

1.95

2.02

2.18

2.33

1.75

1.96

2.07

2.14

2.32

2.48

2.00

2.24

2.37

2.45

2.65

2.83

2.25

2.52

-

-

-

-

Section: Troubleshooting

□

Clean the cad cell, if applicable.

□

Make sure Low Firing Rate Baffl e is in place, if

required, for the burner application. Omitting the baffl e

can result in unacceptable burner combustion.

□

Inspect all gasket including the igniter base plate

gasket. Replace any that are damaged or missing.

□

Clean the blower wheel, air inlet, air guide, retention

head and static plate of any dirt, asphalt or other

material.

□

Check motor current. The amp draw should not

exceed the nameplate rating. Check all wiring for

loose connections or damaged insulation.

□

Check the pump pressure and cutoff function.

□

Check primary control safety lockout timing, if

applicable. Refer to the information supplied by the

control manufacturer for procedures.

□

Check ignition system for proper operation.

□

Inspect the exhaust system for soot accumulation or

other restriction.

□

Clean the equipment thoroughly according to the

manufacturer’s recommendations.

□

Check the burner performance using test

instruments.

□

It is good practice to make a record of the service

performed and the combustion test results.