Parts replacement – Nexen MBU-875 930200 User Manual

Page 13

13

FORM NO. L-20134-J-1211

MODULAR DRIVE UNIT (MDU)

Models 625 and 875

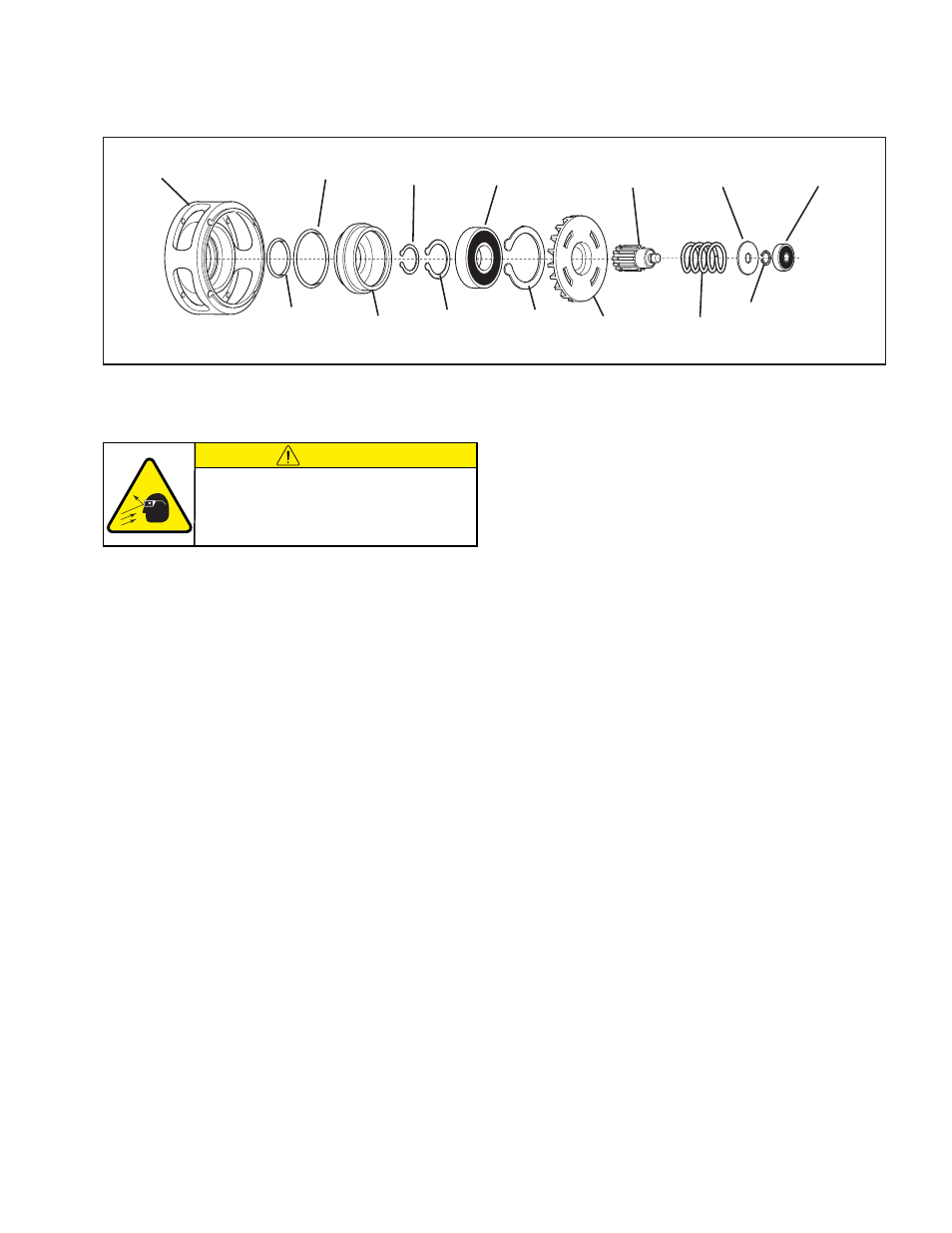

1. Remove the old Ball Bearing (Item 27) (See Figure 12).

2. Remove the Retaining Ring (Item 36) from the Hub (Item 6)

(See Figure 12).

3. Slide the Hub (Item 6), Compression Spring (Item 14),

Spring Retainer Washer (Item 16) and Retaining Ring (Item

34) out of the Friction Disc (Item 7) (See Figure 12).

4. Press the Piston (Item 4), Friction Disc (Item 7), and Ball

Bearing (Item 26) out of the Housing (Item 1) (See Figure

12).

5. Remove the old O-ring Seals (Items 41 and 43) from the

Piston (Item 4) and Housing (Item 1) (See Figure 12).

6. Remove the Retaining Ring (Item 37) from the Friction Disc

(Item 7); then, using a bearing puller, remove the Piston (Item

4) and old Ball Bearing (Item 26) from the Friction Disc (Item

7) (See Figure 12).

7. Remove the Retaining Ring (Item 40) from the Piston (Item

4) and press the old Ball Bearing (Item 26) out of the Piston

(See Figure 12).

8. Clean the bearing bore of the Piston (Item 4) with fresh

solvent, making sure all old Loctite

®

residue is removed (See

Figure 12).

9. Apply an adequate amount of Loctite

®

680 to evenly coat

the outer race of the new Ball Bearing (Item 26) and press

the new Ball Bearing into the Piston (Item 4) (See Figure

12).

10. Reinstall the Retaining Ring (Item 40) (See Figure 12).

11. Support the inner race of the new Ball Bearing (Item 26);

then, press the Friction Disc (Item 7) into the Piston (Item

4) and new Ball Bearing (Item 26) (See Figure 12).

12. Reinstall the Retaining Ring (Item 37) (See Figure 12).

13. Lubricate the new O-ring Seals (Items 41 and 43) and the

O-Ring contact surfaces of the Piston (Item 4) and Housing

(Item 1) with a thin film of fresh O-Ring lubricant (See Figure

12).

14. Install the new O-Ring Seals (Items 41 and 43); then, slide

the Piston (Item 4) and Friction Disc (Item 7) into the Housing

(Item 1) (See Figure 12).

15. Inspect the Compression Spring (Item 14) for signs of fatigue

and replace it if necessary (See Figure 12).

16. Apply a thin film of Never-Seez

®

to the splines of the Hub

(Item 6); then, slide the Hub, Compression Spring (Item 14),

Spring Retainer Washer (Item 16) and Retaining Ring (Item

34)into the Friction Disc (Item 7) (See Figure 12).

17. Reinstall the Retaining Ring (Item 36) (See Figure 12).

18. Slide a new Ball Bearing (Item 27) onto the Hub (Item 6)

(See Figure 12).

FIGURE 12

14

27

16

34

6

7

40

26

37

36

4

43

41

1

PARTS REPLACEMENT

(continued...)

CAUTION

Special attention should be exercised

when working with retaining rings. Always

wear safety goggles when working with

spring or tension loaded fasteners or

devices.