Metalfab Hindon-Invicta L Series User Manual

Page 6

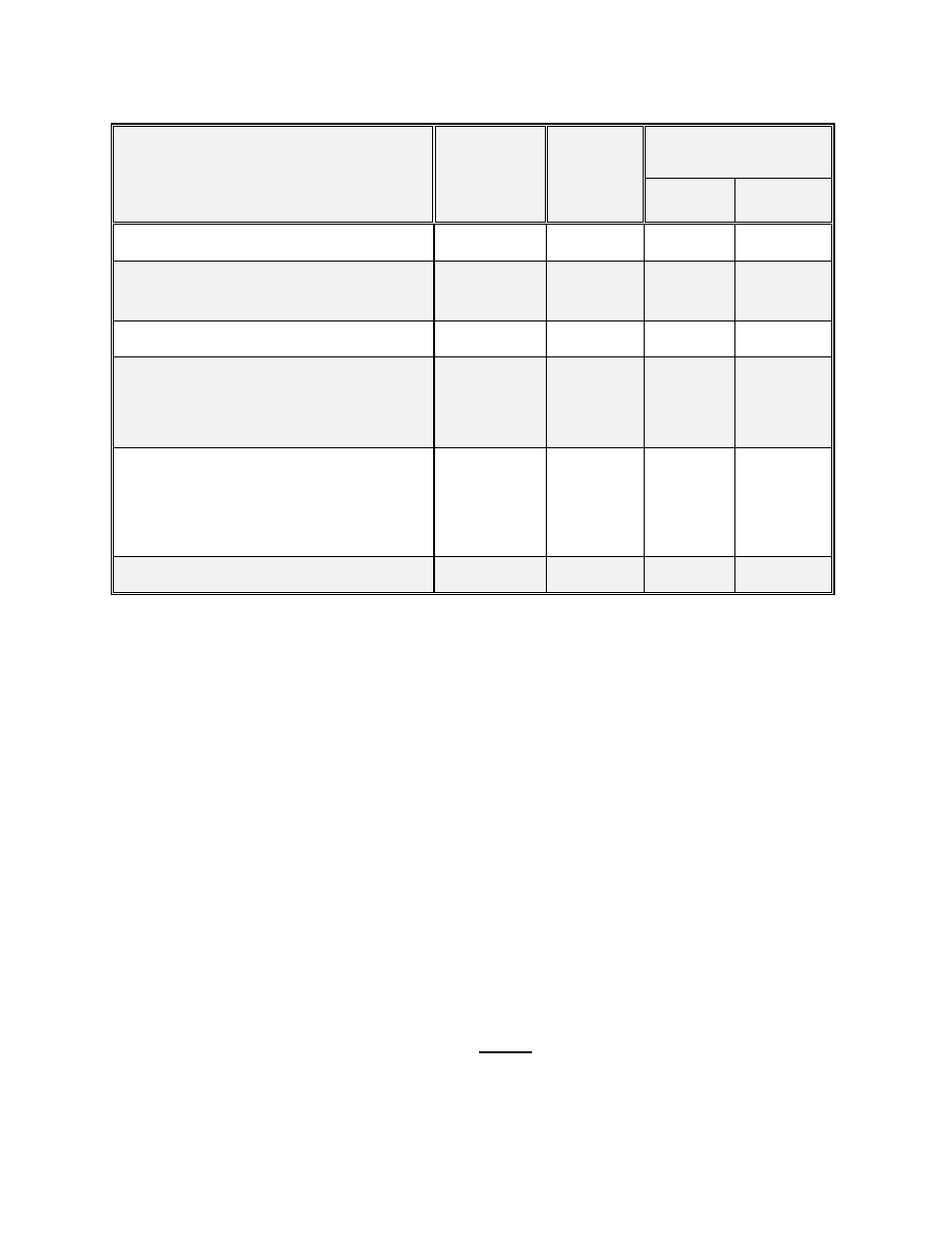

4

* TORQUE (BY NUT)

(LBS-FT)

VIBRATOR MODEL

MOUNTING

HOLE

(Diameter)

BOLT

SIZE

(Diameter)

GRADE 5

GRADE 8

BL 03-1/2, 0.5/4

.33" and .35”

5/16" – 18

18

28

BL 05-2/2, -1/4, -2/4

BL 15-3.5/2, -3/4

.41"

3/8" – 16

31

43

BL 20-5/2, 5/4

.54"

½" - 13

75

106

BL 24/25-8/2, 10/2, 13/2, 7.5/4, 11/4, 14/4,

4/6, 8/6, 11/6

BL 30-16/2, 20/2, 18/4, 25/4, 14/6, 18/6,

23/6, 7.5/8, 10/8

.66”

5/8" - 11

150

209

BL 40-30/2, 40/2, 35/4, 27/6, 35/6, 17/8

BL 45-45/4, 42/6, 50/6, 24/8, 35/8

BL 50-50/2, 55/4, 65/4, 75/4, 60/6, 75/6,

45/8, 57/8

BL 60-95/4,105/4, 90/6, 105/6, 70/8, 90/8

1.02"

1" - 8

583

825

BL 75-130/4, 150/6, 185/6, 150/8

1.29"

1 1/4" - 7

1105

1792

Table 2: Vibrator Mounting Bolt Torque Values (NC Threads)

* Values are for non-lubricated, unplated carbon steel fasteners. Please contact Hindon for further

information if other types of fasteners are to be used.

3.2

Electrical

It is a good policy, prior to vibrator mounting, to measure winding insulation resistance by

meggering; this reading should be greater than 1 megohm. If the winding has become damp, resulting in

an unacceptable megger reading, the stator winding must be thoroughly dried and re-meggered and a

satisfactory reading obtained prior to vibrator installation. In the event of an unacceptable megger reading,

please contact Hindon Corporation directly and advise reading along with vibrator model and serial

number. Most vibrators are dual voltage 230/460 (verify electrical data by reviewing the vibrator

nameplate) and are normally factory configured for 460 Volt operation. For 575 Volt winding “Star”

connection as shown in figure 2 (pg. 5) would apply. Configuring for 230 Volt operation is easily

accomplished by adjustment of the link plates (buss bars) on the terminal block. For specific terminal box

connections, please refer to Figures 2 and 3 on the following page. For details on wiring of thermistors

that are supplied in Invicta models BL 24 – BL 75, please refer to section 3.2.3

3.2.1

Cable Connection

Attach flexible 4-conductor type "SO" cord (allowing for "drip or vibration loop") and

suitable watertight connector to terminal box entry. NOTE: For added safety, electrical power cord must

be installed with sufficient slack to allow vibration, and so that condensation will "drip" from bottom of

loop.