Socket head – Metalfab Hindon-Invicta L Series User Manual

Page 5

3

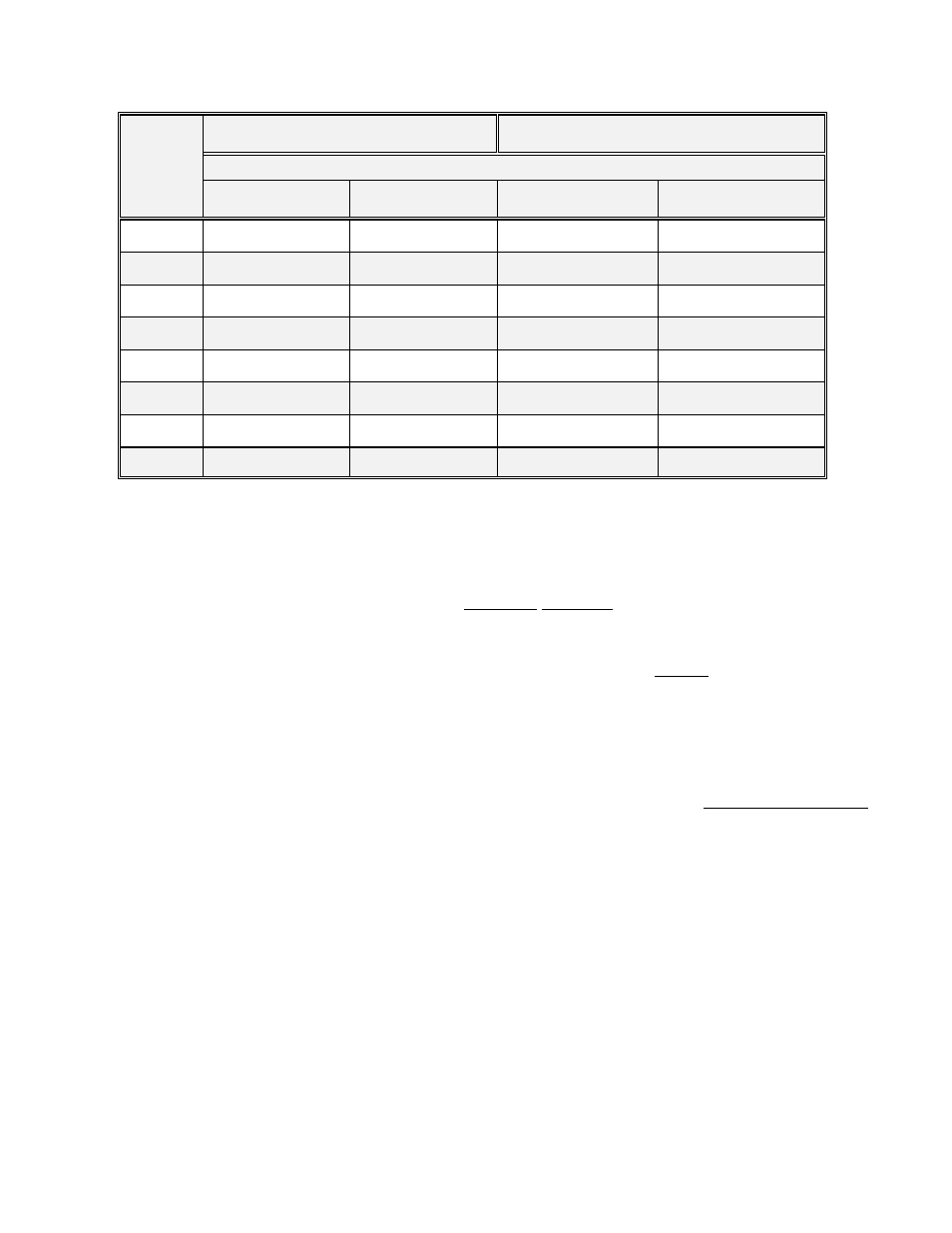

SIZE

INTERNAL FASTENERS

(EXCLUDING O/B WEIGHTS)

O/B WEIGHT FASTENERS

* TORQUE (LBS-FT)

SOCKET HEAD

CAP SCREWS

HEX HEAD

BOLTS

SOCKET HEAD CAP

SCREWS

HEX HEAD

BOLTS

M5

6

-

5

-

M6

11

8

8

8

M8

25

20

20

20

M10

50

41

41

41

M12

94

71

71

71

M16

228

178

130

178

M20

-

348

-

348

M24

-

602

361

602

* Values are for factory supplied fasteners.

3.1.1

Vibrator Mounting

It is recommended that the fasteners (bolts, nuts and hardened flat washers) be a minimum

of grade 5 and a maximum of grade 8. It is extremely important to follow the guidelines below for

safe and proper vibrator mounting:

1)

Vibrator must be mounted upon a flat or machined, rigid base. NOTE: If the base is not flat

or is able to flex under load, the vibrator can come loose.

2)

Ensure that no paint or other foreign matter exists on any of the mating surfaces being bolted;

either at the washer seatings or on the vibrator foot or vibrator mounting beams.

3)

For all vibrator models, the mounting bolts must be provided with hardened flat washers

under the bolt heads and under the nuts. Ensure that entire outside diameter of washer seats

within the spot facing of the mounting hole.

4)

The nuts must be pre-tightened until all the mating surfaces are brought into contact. The

nuts must then be tightened using a torque wrench in accordance with torque values as

detailed in Table 2. (Use a criss-cross pattern for torquing sequence).

5)

After approximately 30 minutes of initial vibrator operation, the unit should be switched off

and all mounting bolts checked and re-tightened with a torque wrench to the values stated

in Table 2. After one to two hours of operation, this tightening procedure should again be

repeated. If any loosening of the mounting bolts has occurred during this initial period,

check flatness of mounting plate and vibrator base to ensure a proper "seating" of the two

surfaces.