Mounting bolt installation, 1 mounting bolt installation – B&C Technologies SP Series Commercial User Manual

Page 23

For a successful installation, a smooth level surface, so that the entire base of the machine is sup-

ported and rests on the mounting surface, is absolutely requried.

Note: Do not support the machine on only four points.

Note: Freestanding washer-extractors do not require anchoring bolts unless specified by state

or local codes. However it is always recommended that the machines be anchored.

Special care must be taken when machines are installed on an upper floor. Make sure that the floors

are designed to carry the static and dynamic loads of the machines. Further vibrations should be

taken into consideration so that the machine does not create vibrations in the building. Static and

dynamic loads on the floor or foundation are shown in the figure 4.1 on page 19. This table can

be used as reference when designing floors and foundations. See the figures beginning on page

20 for mounting bolt layout measurement and pattern.

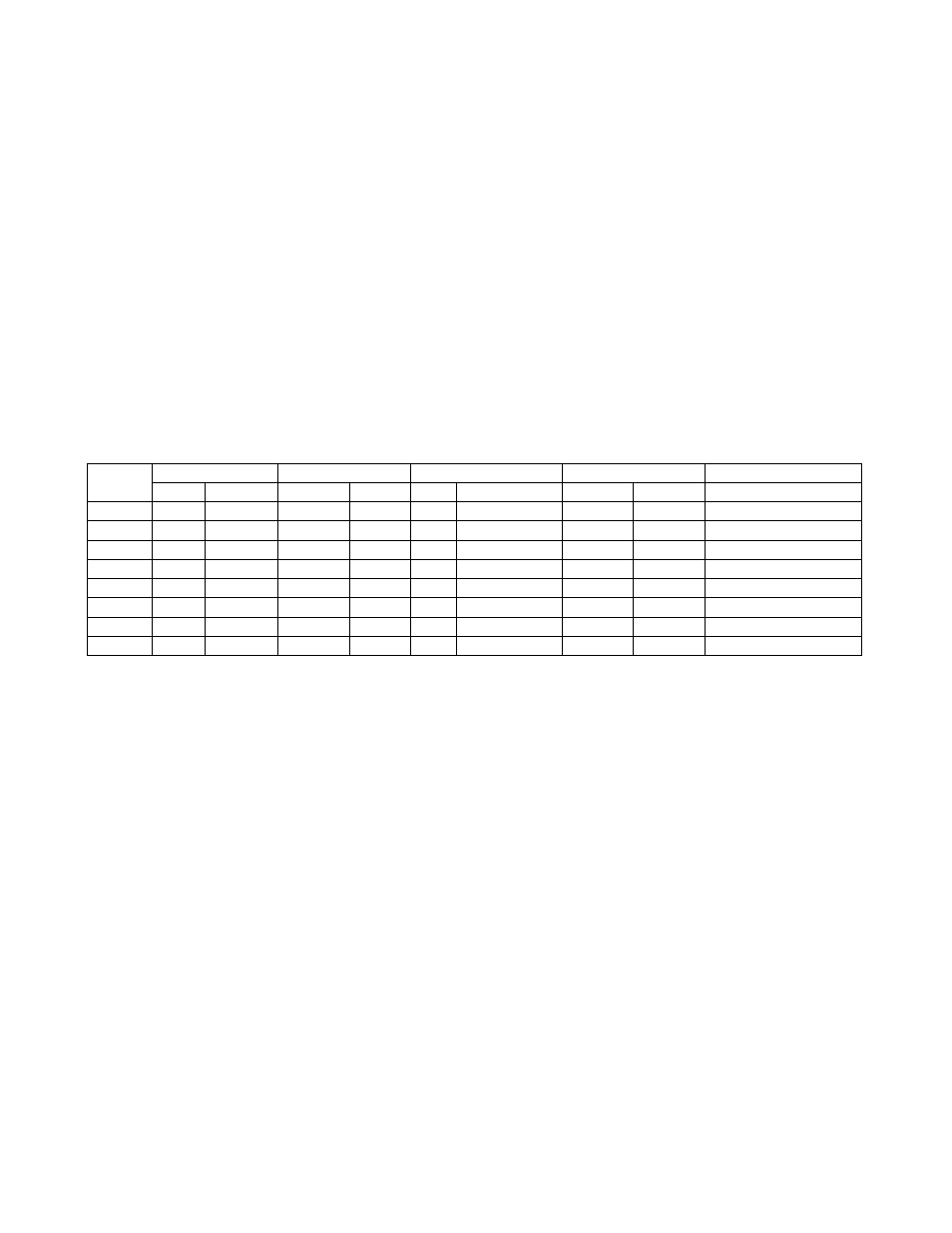

Table 4.1: Floor Load Data

Static floor load

Static pressure

Dynamic floor load

Dynamic pressure

Dynamic Frequency

kN

lbs

kN/m2

lbs-ft2

kN

lbs

kN/m2

lbs-ft2

Hz

SP-45

7.28

1635

7.21

150

2.8

631

2.8

58

16

SP-50

7.64

1718

7.17

150

3.1

701

2.9

61

16

SP-65

8.41

1890

6.8

142

4

909

3.3

68

14.8

SP-75

8.9

2001

6.8

142

4.7

1048

3.6

74

14.8

SP-110

13.34

2999

7.95

166

6.9

1542

4.1

85

13.6

SP-135

14.88

3344

7.15

149

8.4

1893

4

85

12.8

SP-165

22.64

5089

8.5

178

9.4

2116

3.5

74

12.1

SP-195

24.53

5514

8.59

179

11.1

2505

3.9

81

11.7

4.4.1

Mounting Bolt Installation

All SP Machines use 1/2-13 bolts. Embed the bolts in 3500 psi reinforced concrete with a minimum

of 4”’ thickness. The threaded end of the bolt should extend 2 inches from the surface of the floor.

Grouting is recommended, but not required.

19