Xpres Cut Plus: Ultragraphics Roland GX-24 Manual User Manual

Page 4

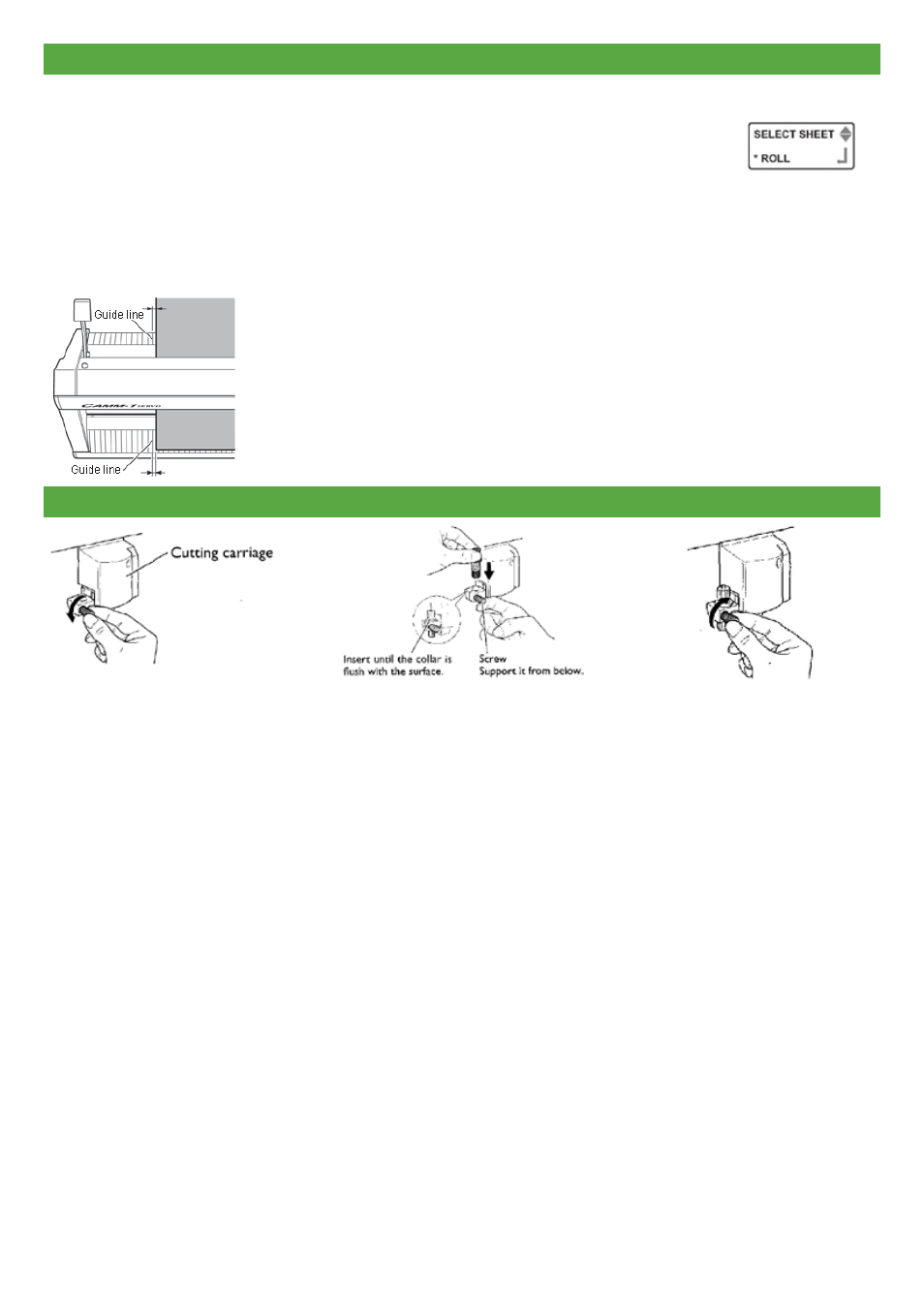

Loading garment film continued

Installing & changing Xpres blades

4

5.

Align the left edge of the material so that it lies parallel to

the guide lines.

note:

• Do not use excessive force when moving the loading

lever. Doing so may damage it.

• If the condition of the material is as described below,

then stretch or flatten it before use.

* the material is curled upward.

* the leading edge of the material is bent or creased.

1.

Loosen the screw of the cutting

carriage

2.

support the screw from below and

insert the blade.

note:

If the blade

is installed without supporting the

screw, blade damage may occur.

3.

tighten the screw.

tip:

to ensure the

blade has been installed correctly,

tug upwards on the blade to make

sure the blade is tight enough.

6.

Raise the loading lever. the material is now secured in

place.

7.

turn on cutter, the display will read.

Press the ‘enteR’ key.

8.

the head will now move over to the left hand side and

give a width reading. note: the width is determined by

the distance between the inside of the pinch rollers, not

the width of the material.

9.

You can now use the cursor keys on the cutter to

position the head/material start point. When you have

the correct start point of the material press and hold the

origin button. the display will flash ‘origin set’.

10.

Adjust your blade force as required (see below) for the

type of material you are using.

Blade Usage:

XP2006

(blue tip)

is used for all vinyl based print and garment film.

XP2005

(red tip)

is used for all flock based print and garment film.

Blade Force:

After loading the material into the cutter you may need to change the force. Press the ‘FoRce’ button, then

press the RIGHt arrow key and use the UP and DoWn arrow keys to increase or decrease the force as desired. once the

required force is set, press enteR.

cutting Depths

For use with Roland cX/GX-24

Garment Films

easy cut:

60 - 80gf

easy Flex:

90 - 100gf

extra Flex:

90 - 100gf

Fashion Range (excluding sparkle & textile Foil):

90 - 120gf

Flexi cut:

110 - 120gf

Multi Flex:

90 - 100gf

nylo Flex:

90 - 100gf

Premium Flock:

90 - 110gf (Flock Blade)

Promo Flock:

60 - 80gf (Flock Blade)

sparkle:

140 - 180gf (Flock Blade)

super Flex:

90 - 100gf

textile Foil:

120 - 140gf

thermo Reflective:

90 - 110gf

Ultra cut:

90 - 100gf

Glossy Flex:

90 - 100gf

Full colour transfer

Dark Jet:

60 - 80gf

Inkjet Dark:

70 - 90gf

subli Flock:

80 - 100gf (Flock Blade)

sign Vinyl

sign Vinyl:

90 - 110gf

Gem tec

stencil Film:

200gf + (Flock Blade)

Use the ‘test’ button on the cutter to obtain the correct depth, by starting at the recommended minimum depth above and

increasing in increments of 10gf. All forces above have been taken using a new blade, and can differ from cutter to cutter.