Vetter Struts and Accessories User Manual

Page 22

Page 22/24

AIRSHORE Struts and Accessories for Rescue

5.

Repair and Maintenance

Airshore ART struts and accessories must be visually checked after every

deployment and/or use to ascertain that they are complete and unda-

maged. At least once a year a visual and functional test of the ART struts

and the accessories must be carried out.

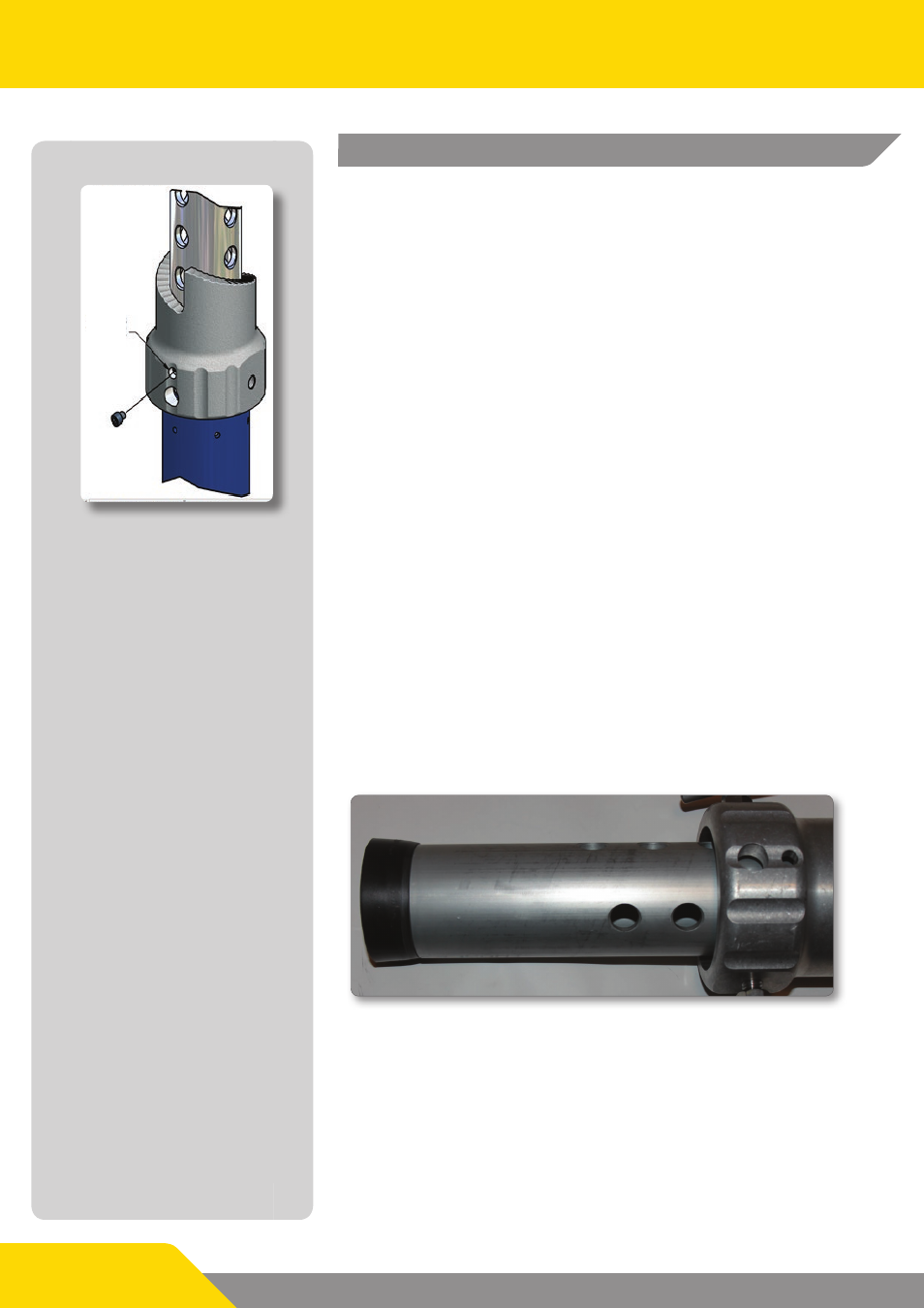

1. Remove both inner hexagon screws in the pipe. They can be reached

via the access hole in the sleeve. Turn the sleeve by 90° to remove

the second screw.

2. Pull the piston (together with sleeve) out of the support tube. Should

you insert the safety pin during cleaning or visual check through the

drill hole into the sleeve, you can pull the sleeve out of the ART strut

together with the piston.

3. Clean the ART strut and the accessories by washing with a cleaning

brush and soapy water. In the case of extreme contamination, you

can clean with a high pressure cleaner.

4. Check the ART strut and its accessories for damage, completeness and

function!

9

Connecting nipple and end cap - permeability, protective cap

9

Overflow opening – free flow

9

Sleeve with T-grips - function and ease of turning, check threads

9

Lock – smooth motion and function

9

Piston seals - undamaged and smooth motion

5. Check the rubber cap at the bottom of the piston. It should sit tight-

ly and be round. Check the elasticity of the rubber cap every 2-3

months by hand to maintain its shape. Spray the cap regularly with a

non-petroleum based silicone.

6. Piston seals must not be cleaned with an aggressive and/or hydroge-

nous cleaning agent!

7. Assemble the pistons and support tube again and check for perfect

functioning and a smooth motion.

8. Accessories – attachments, clevises and base plates must also be re-

gularly checked! Make sure that all adjusting screws, safety pins and

locks are available and function perfectly!

Access

hole