Tjernlund XCOP1 Constant Operating Pressure Exhaust Control 8504175 (Discontinued) User Manual

Page 6

5

PRESSURE SENSING TUBE INSTALLATION

1. Follow sensing tube location recommendations on page 4.

Use a sharp drill bit to reduce burr, drill a 1/4" hole for pressure

sensing tube. Screw sensing tube bracket to duct/chase with

sampling hole centered, (See Diagram C).

2. Insert stainless steel sensing tube through 1/4" hole enough to

just penetrate interior of duct/chase and lock in place with com-

pression ferrule and nut, (See Diagram C).

ADJUSTING THE PRESSURE (EXHAUST) SET POINT

1. Verify that slot on set point adjustment pot for the COP controller is aligned with the "20" hash mark, (See Diagram D).

2. Provide power to the XCOP1 by turning on circuit breaker or disconnect or activating dryers if using a dryer duct pressure switch.

3. Verify that the RT-Series Fan activates by seeing the draft pressure increase (more negative) on your draft gauge as measured

with a tee at draft sensing position, (See Diagram E). Gradually adjust the pot on the XCOP1 controller circuit board clockwise.

The RT-Series Fan should speed up increasing the negative exhaust pressure. Slowly adjust the pot on the XCOP1 controller

counter-clockwise until the exhaust pressure is maintained at -0.10" w.c.. NOTE: Turning the adjustment pot too far counter-

clockwise will cause the RT-Series Fan to stall or not be able to start. Readjust clockwise if necessary.

ADJUSTMENT OF BALANCING BAFFLE(S) FOR KITCHEN AND BATH FANS

IMPORTANT: Balancing Baffles must not be used for dryer applications due to the potential for lint buildup.

1. With all balancing baffles closed and starting with connection at lowest floor drill a small sampling hole in duct connection to the

chase 1 foot behind the Balancing Baffle (opposite side of chase connection).

2. With the XCOP1, RT-Series Fan and Bath/kitchen fans connected to the duct operating, gradually open the Balancing Baffle

until desired negative exhaust pressure is measured and lock in place. Typically a measurement of a -0.02 to -0.05" w.c. is

adequate.

3. Repeat steps 1 and 2 for each floor, moving up towards the RT-Series Fan.

TROUBLESHOOTING ELECTRICAL PROBLEMS

It is necessary to measure voltage during troubleshooting. Extreme caution must be exercised to prevent injury. If you are

unable to determine the defective part with the use of this guide, call your Tjernlund distributor or Tjernlund Products direct at

1-800-255-4208 for further assistance.

RT-SERIES FAN MOTOR DOES NOT OPERATE

Verify the XCOP1 control has power by checking for 115 VAC at the input power terminal strip positions L1 and N. If no voltage is

measured check circuit breaker, disconnect switch or any other switch between disconnect and XCOP1 control.

Voltage present: Verify wiring connections between XCOP1 and RT-Series Fan. Check adjustment pot on XCOP1. Too low of an

adjustment may stall RT-Series Fan. Adjust clockwise to see if RT-Series Fan speeds up. If RT-Series Fan does not speed up and

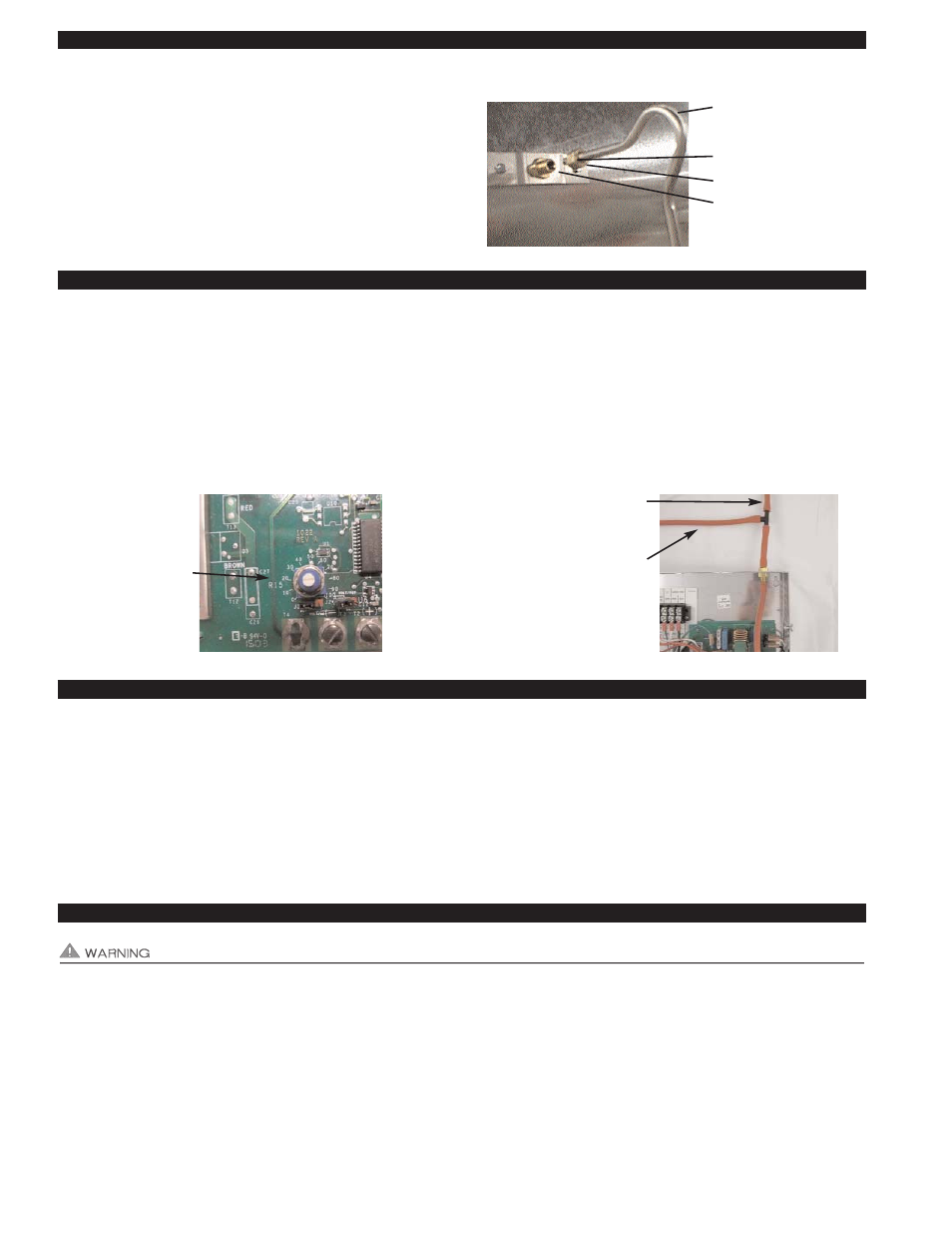

DIAGRAM C

1/4” STAINLESS STEEL

SENSING TUBE BEND MUST

FACE UPWARD

COMPRESSION FERRULE

COMPRESSION NUT

SAMPLING PORT CENTERED

OVER 1/4” HOLE

DIAGRAM E

TO PRESSURE SENSING

TUBE IN VENT COMMON

MANIFOLD

TO DRAFT GAUGE

DIAGRAM D

XCOP1 DRAFT

ADJUSTMENT POT

AND SCALE. CLOCK-

WISE WILL INCREASE

DRAFT.