Symtech LCA2 EZ User Manual

Page 5

5

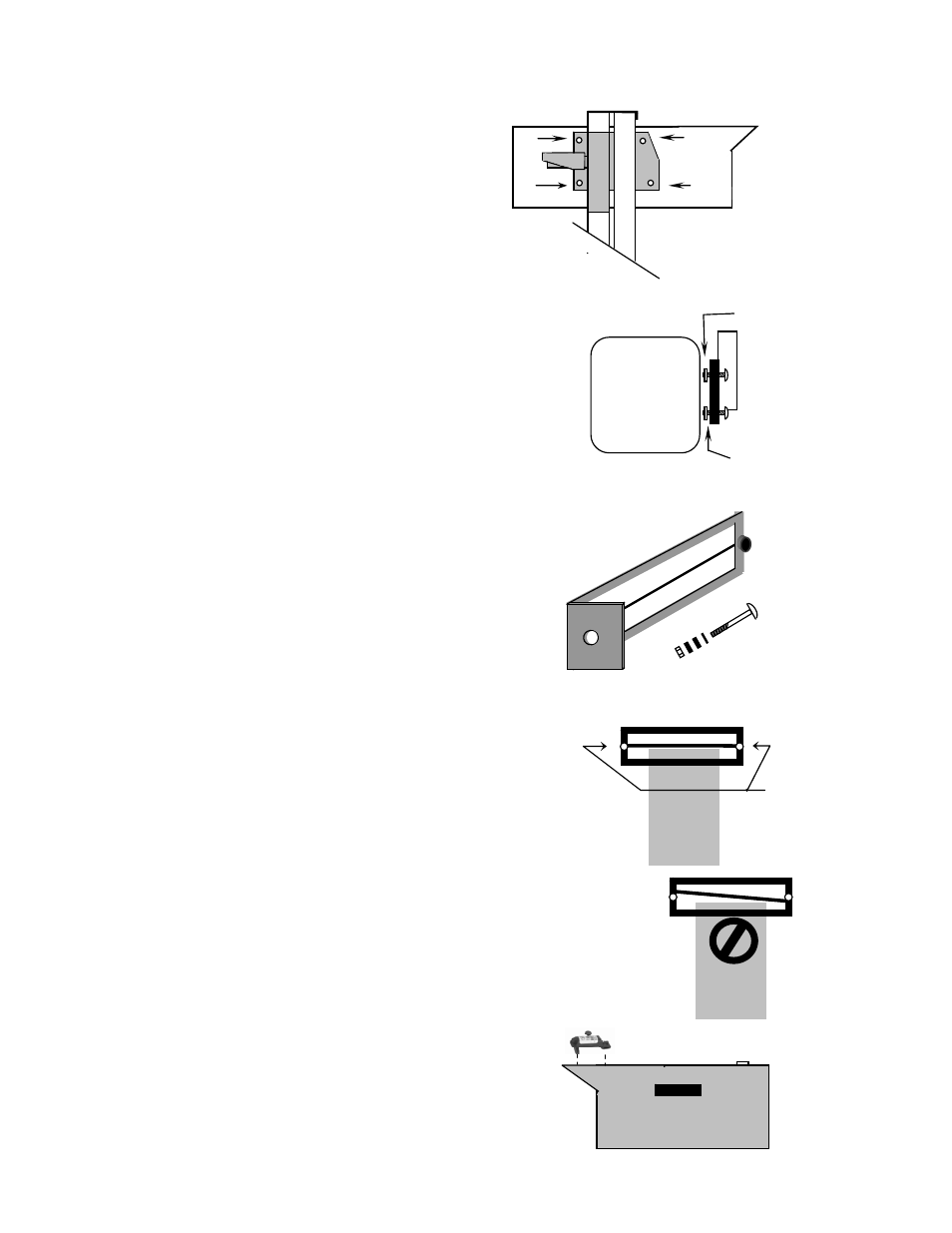

2.3 OPTICAL ALIGNMENT HEAD

Remove optical alignment head from shipping carton.

Inspect for any damage that may have occurred during

shipment i.e. lens, case, etc..

Attach optical alignment head to the mast glide plate by

aligning mounting holes of glide plate with the holes in

the optical head. Insert ¼” x 20 x ¾” allen head machine

screws through glide plate, place a ¼” x

1

/

8

” (WHITE)

nylon spacer on each upper attachment screw, place a ¼”

x ¼” (BLACK) nylon spacer on each lower attachment

screw, attach optical head and tighten securely.

Remove protective paper covering from viewing window

on top of optical head.

Move optical head through the full range of movement to

assure of smooth operation.

2.4 SIGHTING UNIT

Sighting unit is the “L” bracket assembly enclosed

in the accessories box.

NOTE: Mount sighting unit so that unit is

located directly over the optical head.

Insert the

5

/

16

” x 3” slotted head machine screw with

5

/

16

” nylon washer into the sighting unit.

Place a small nylon bushing on the screw and insert

screw through the holes provided at the top of the

mast, place two large nylon bushing on screw, sight

unit, and self-locking nut.

Tighten to a tension that allows for movement of

sighting unit, but provides sufficient friction to hold

unit in place when unattended.

NOTE: Sighting unit must be calibrated to the optical head prior

to alignment of headlamps.

2.5 SIGHTING UNIT CALIBRATION

Calibration of sighting unit must be performed prior to alignment of

headlamps.

Raise optical head of LCA 2

EZ

to the approximate center of

travel of mast.

Turn the sighting unit until you can see the front edge of the optical

head while looking through the sighting unit lens. Line on lens

should line up with the front edge of the optical head.

If line does not line up with the front edge of optical head, loosen

the thumbscrews on the lens and move the lens into alignment.

Tighten thumbscrews.

It is important that periodical checking of calibration of the sighting

unit be performed, to assure customer satisfaction.

NOTE: When technicians of differing heights are using the LCA

2

EZ

and the sighting unit is rotated for better viewing,

the sight unit must be checked for calibration and

adjustment made accordingly.

2.6 FLOOR SLOPE LASER

The floor slope laser assembly is factory calibrated, DO

NOT turn the level adjustment set screw.

Optical

Head

IN

Calibration

OUT of

Calibration

Adjustment

Thumb Screws

Optical

Head

¼” x 20 x ¾”

Allen head

Glide

Plate

Optical

Head

¼” x

1

/

8

”

Nylon Spacers

(WHITE)

¼” x ¼”

Nylon Spacers

(BLACK)