Assembly – Symtech LCA2 EZ User Manual

Page 4

4

1.4 VISUAL ASSIST METER & SWITCH

The “Visual Assist” meter is an aide for positioning the headlamp

pattern to its correctly designed position. While visually adjusting

the headlamp into position, the “Visual Assist” meter will raise in

numeric reading if adjustment is directed in the correct direction.

Adversely, the meter reading will decrease if headlamp is adjusted in

the incorrect direction. When the highest achievable reading is

attained both vertically and horizontally, the headlamp will be

positioned correctly.

The SELECTOR switch moves the “Visual Assist” meter function

between High and Low Beam patterns. Make sure that the switch is

in the correct location for the beam pattern to be aligned.

2. ASSEMBLY

Inspect all components of the LCA 2

EZ

system to assure that no damage has occurred during shipment, compare

contents of package with that of the exploded view to make sure that no component has been inadvertently left out of

packaging. If a component is missing, contact our customer service department at 888-884-8182 for an immediate

replacement.

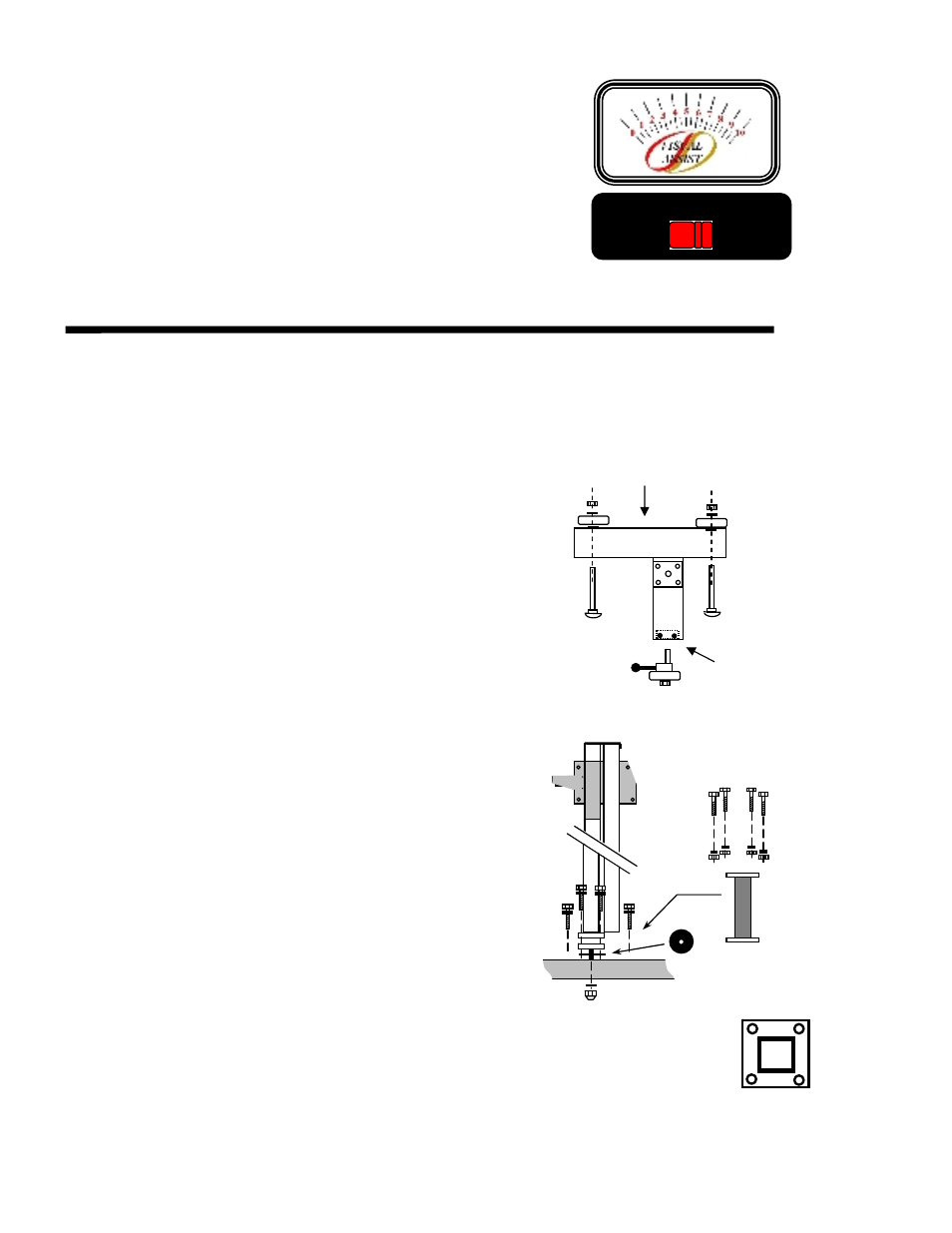

2.1 BASE / WHEEL ATTACHMENT

Place base of system on floor, or table with channel facing

downward.

Insert a 5/16” x 6” carriage bolt into each of the holes noted, making

sure that the square carriage bolt head seats securely into the square

hole placement.

Complete wheel assembly by placing in order a large nylon washer,

wheel, small nylon washer and self-locking 5/16” nut on carriage

bolt.

Tighten self-locking nut snug against wheel, but not so tight as to

hinder free wheel movement.

Insert floor slope eccentric and wheel into mounting block on base

(rear wheel). Tighten friction bolt until floor slope eccentric can be

moved, but not loose enough to move by itself.

2.2 MAST / GLIDE PLATE / ROTATIONAL MAST MOUNT

The Mast, Counterweight Spring Cover, Spring and Glide Plate are

packaged as an assembly.

Remove tie-lock band from base of mast, attach rotational mast

mount to mast with four (4)

5

/

16

” x ¾” bolts and tighten securely,

making note of bolt tightening sequence.

Place rotation bearing over mast stud and insert rotational mast stud

into base. Secure mast to base with

1

/

2

” flat washer and ½” self-

locking nut. Tighten nut securely then back-off ¼ turn, or until

mast rotates freely with minor resistance.

NOTE: Do not incorporate the mast extender in the assembly, if

alignment of vehicle headlamps over 45” in height are not

expected to be assessed. Majority of vehicles will fall

under the 45” allowance, FACT: MOST OVER THE

ROAD TRUCKS and SUV’s FALL UNDER THE 45”

HEADLAMP HEIGHT.

Move glide plate up and down the mast through its full motion, by

depressing handle.

NOTE: if glide plate moves without tension felt from the spring, it

is possible that the spring has dislodged during shipment.

It will be necessary to remove the mast spring cover and

reattach the glide plate spring.

1

3

4

2

TIGHTENING

SEQUENCE

“HIGH”

BEAM

“LOW”

BEAM

VISUAL ASSIST

SELECTOR

Tighten

this Bolt

Front of Base

ROTATIONAL

BEARING