Install the connecting pipe, 1 preparation and caution, 2 the procedure of connecting pipes – Pridiom Concealed Duct Installation Manual User Manual

Page 17: Caution

15

installation manual

NOTE

The service valves of the outdoor unit should be completely

closed(as original status).Every time to connect,first to loosen

nuts, then connect the flare pipes within 5 minutes. If the nuts

have been loosened for a long time, dusts and other impurities

may enter the pipe system and may cause malfunction.So

please expel the air out of the pipe with refrigerant before

connection.

Expel the air(refer to the “8.1”)after connecting the refrigerant

pipe with the indoor unit and the outdoor unit.

Then fasten the nuts at the service valves.

Bend the connecting pipe of small wall thickness.

Cut out a proper concave at the bending part of the

insulating pipe.

Then expose the pipe(cover it with tapes after bending).

To prevent twist of deforming, please bend the pipe at a

proper radius.

Fig.7-3

Make the ends straight

The bending angle should not exceed 90 .

Bending position is preferably in the middle of the bendable pipe.

Do not bend the pipe more than three times.

Be sure to use the same insulating materials when you buy the

brass pipe. (More than 9mm/0.35in thick)

Be sure to use two wrenches simultaneously when you

connect or disconnect the pipes.

7.1 Preparation and Caution

7. INSTALL THE CONNECTING PIPE

Before installation make sure the height difference, the length

of refrigerant pipe, and the number of the bends between the

indoor unit and outdoor unit meet the following requirements:

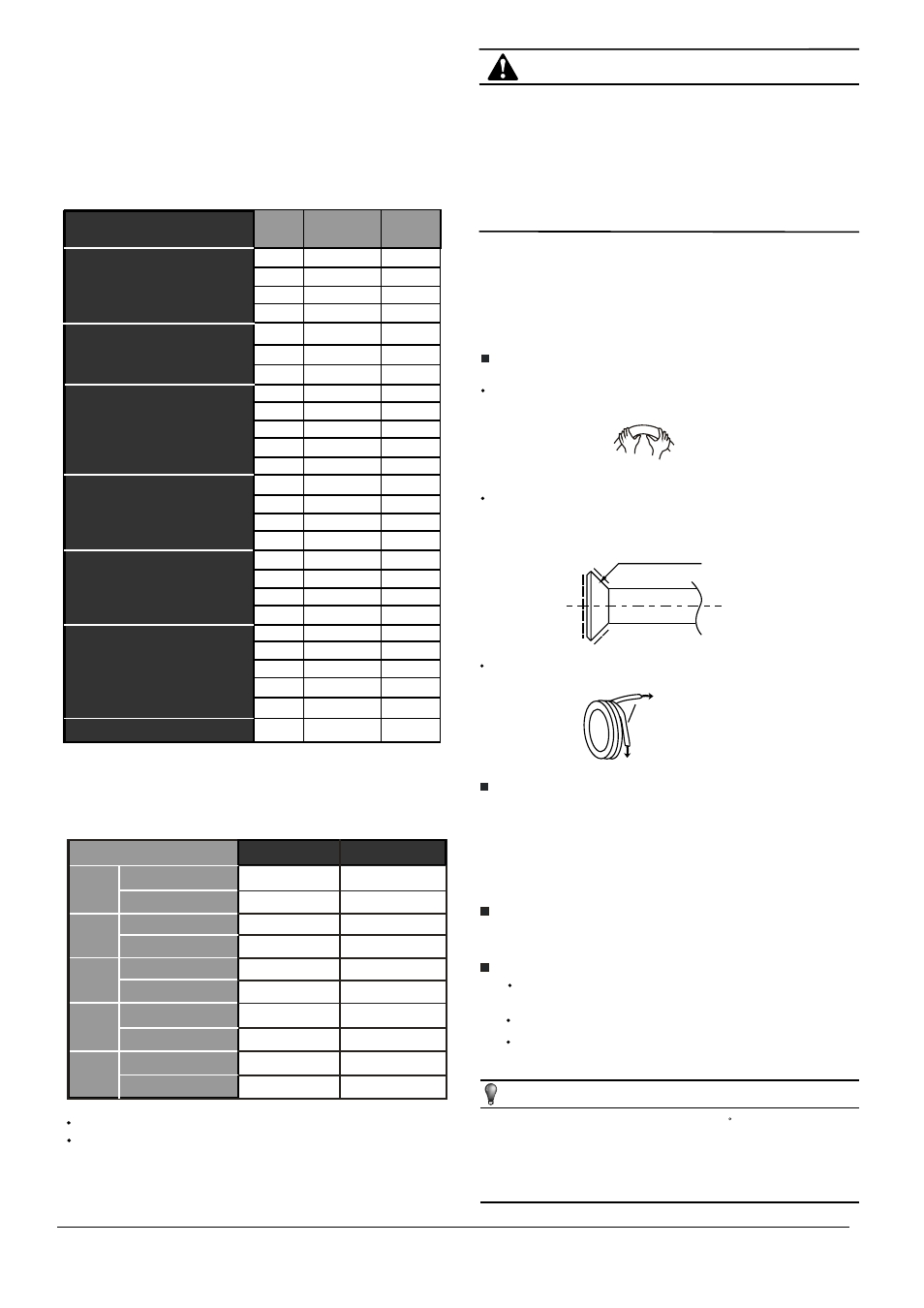

Table 7-1

unit:m

The outdoor unit is charged with rating refrigerant amount in

the factory.Additional charge refers to the table below:

Table 7-2

7.2 The Procedure of Connecting Pipes

Connect the indoor unit first, then the outdoor unit.

Bend the tubing in proper way. Do not twist the pipe.

Bend the pipe with thumb

min-radius 100mm/3.94in

Fig.7-1

Put some refrigerant oil on the surfaces of the flare pipe

and the joint nuts then wrench it for 3~4 rounds with

hands before fasten the flare nuts.(Refer to chart 16)

Use frozen oil

Fig.7-2

Measure the required length of the connecting

pipe, then make it by the following way.

1

All field piping must be provided by a licensed

refrigeration technician and must comply with the

relevant local and national codes.

Prevent let air, dust, or other impurities enter in the pipe

system during installation.

Insulation pipe shall be used to the gas piping and the

liquid piping. Otherwise, the condensate may happen.

CAUTION

liquid tube(mm)

R410A

R22

Ш6.35

Ш9.53

Ш12.7

Ш15.9

Ш19.0

0.022kg/m×(L-5)

0.011kg/m×(L-5)

0.060kg/m×(L-5)

0.030kg/m×(L-5)

0.110kg/m×(L-5)

0.060kg/m×(L-5)

0.170kg/m×(L-5)

0.085kg/m×(L-5)

0.250kg/m×(L-5)

0.125kg/m×(L-5)

0.030kg/m×(L-5)

0.015kg/m×L

0.065kg/m×(L-5)

0.030kg/m×L

0.115kg/m×(L-5)

0.060kg/m×L

0.190kg/m×(L-5)

0.095kg/m×L

0.290kg/m×(L-5)

0.145kg/m×L

orifice in the indoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the indoorunit

orifice in the indoorunit

orifice in the indoorunit

orifice in the indoorunit

Model

12K

18K-24K

30K-42K

12K

18K-24K

30K-60K

48K-60K

12K

18K-24K

30K

48K-60K

36K

50Hz T1 condition/R22

Split type air conditioner

50Hz Vertical discharge air conditioner

/60Hz T1 condition/R22 Split type air

conditioner and Vertical discharge air

conditioner

The type of models

R410A inverter Split type air

conditioner and and Centrifugal

fan outdoor unit

50/164.04ft

50/164.04ft

30/98.42ft

15/49.21ft

50/164.04ft

30/98.42ft

15/49.21ft

30/98.42ft

30/98.42ft

25/82.02ft

10/32.8ft

25/82.02ft

R410A Split type air conditioner

and and Centrifugal fan outdoor

unit

50Hz/60Hz T3 condition

(outdoor unit down)

50Hz/60Hz T3 condition

(outdoor unit up)

the unit with quick joint

12K

48K-60K

18K-30K

36K

18K-24K

42K-60K

30K

36K

18K-24K

12K-18K

48K-60K

42K

30K

36K

50/164.04ft

25/82.02ft

15/49.21ft

30/98.42ft

50/164.04ft

30/98.42ft

25/82.02ft

30/98.42ft

25/82.02ft

50/164.04ft

30/98.42ft

30/98.42ft

50/164.04ft

15/49.21ft

35/114.83ft

5/16.4ft

5/16.4ft

25/82.02ft

20/65.62ft

30/98.42ft

25/82.02ft

15/49.21ft

8/26.25ft

20/65.62ft

25/82.02ft

15/49.21ft

10/32.8ft

20/65.62ft

20/65.62ft

25/82.02ft

12/39.37ft

5/16.4ft

15/49.21ft

25/82.02ft

10/32.8ft

8/26.25ft

20/65.62ft

10/32.8ft

8/26.25ft

20/65.62ft

refrigerant pipe

The length of

height drop

The max

NOTE:The number of bends is up to the length of the max

height drop.Usually for each 10m/32.8ft need a bend.

NOTE:the table above refer to the liquid tube.