Stack-frame-assy, Stack system anchoring, Stack frame assembly and installation – Oldcastle BuildingEnvelope FG-2000 User Manual

Page 12

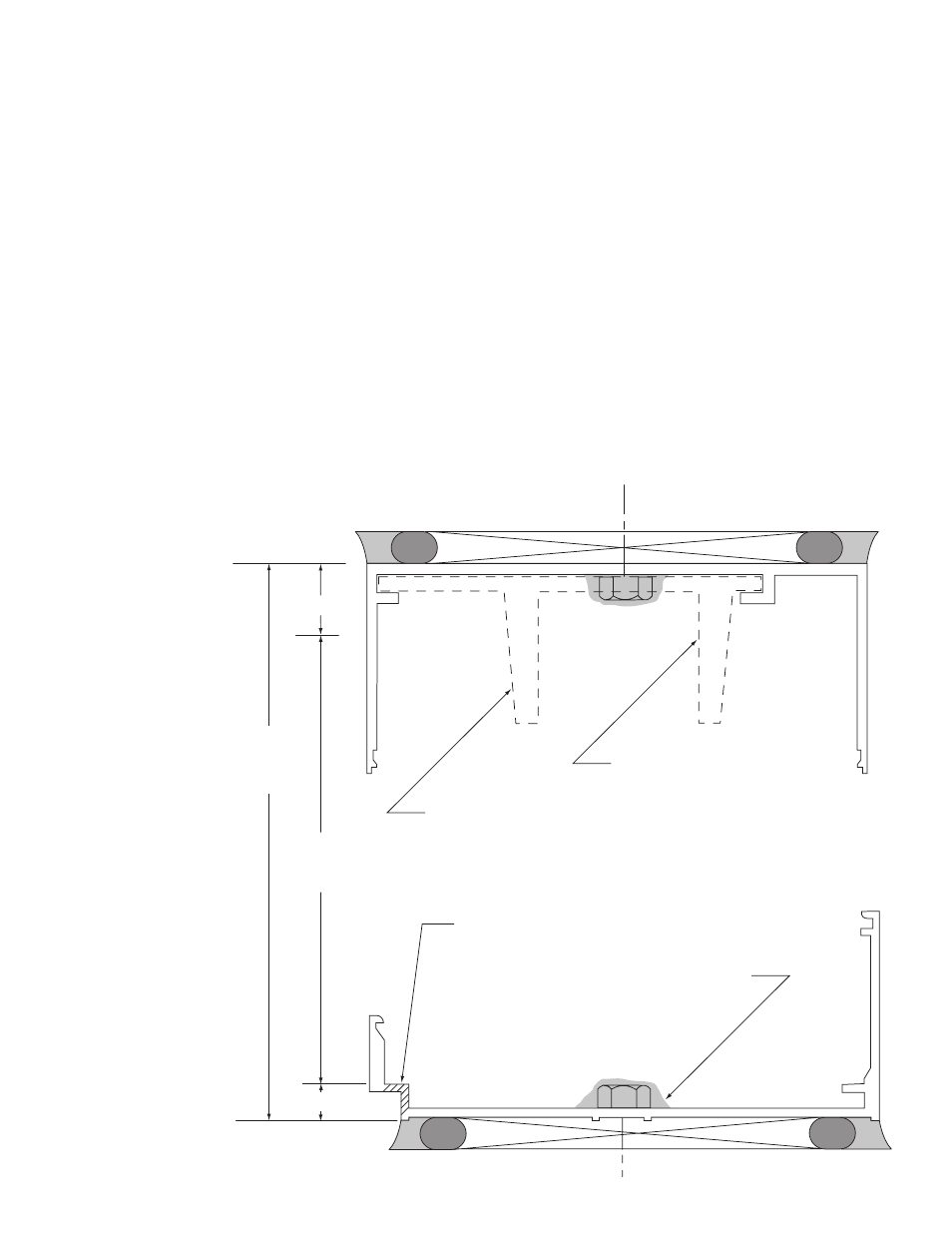

STACK FRAME ASSEMBLY AND INSTALLATION

The assembly and sealant procedures are a part of the installa-

tion sequence because of the stacking method.

HEAD CAN:

Anchor screws should be within 4" of each side of the intended

mullion location. Head anchors (AC-109-1 PART #: 6554) should

be used if the height x width x design load is 500 lbs. or more at

the top of the mullion. Normally one anchor screw at the middle

of the lite or 24" O.C. is adequate for securing the header. For

unusual conditions, consult

™

engineering department.

SILL CAN:

Shim can a minimum

1

⁄

4

". Anchor sill can 24" O.C. and no more

than 4" on each side of intended mullion locations. Be sure

weeps are located under center line of mullion. Seal both sides

of can.

HORIZONTAL HEAD AND SILL INSERTS:

Members are cut

1

⁄

16

" less than daylight opening to allow for

incremental expansion.

JAMB MEMBERS:

Remember all horizontals are cut 1/16" short. Do not over shim

between jamb and structure.

MULLIONS:

Cut mullion length outside frame dimension minus 1

8

". Install mulls

1/

by sliding top end over anchor and rotating bottom into position.

RECOMMENDATION:

Prior to glazing, fill sill cavity with water to assure that end dams

and anchors are sealed.

STACK SYSTEM

ANCHORING

AC-109-1 PART #: 6554

MULLION ANCHOR ROTATES

INTO HEAD CAN.

1/4" DIA. WEEP HOLE AT CENTER

LINE OF INTERMEDIATE MULLIONS.

CAP SEAL ALL HEAD AND

SILL CAN ANCHORS.

-3/4"

3/8"

MULLION

HEIGHT

FRAME

DIMENSION

11

FEBRUARY 2012

F L U S H G L A Z E S E R I E S 1 0 0 0 a n d 2 0 0 0 I N S T A L L A T I O N M A N U A L