27_expansion_mullion – Oldcastle BuildingEnvelope 6000 Series Thermal MultiPlane User Manual

Page 28

27

S E R I E S 6 0 0 0 T H E R M A L M U L T I P L A N E I N S T A L L A T I O N M A N U A L

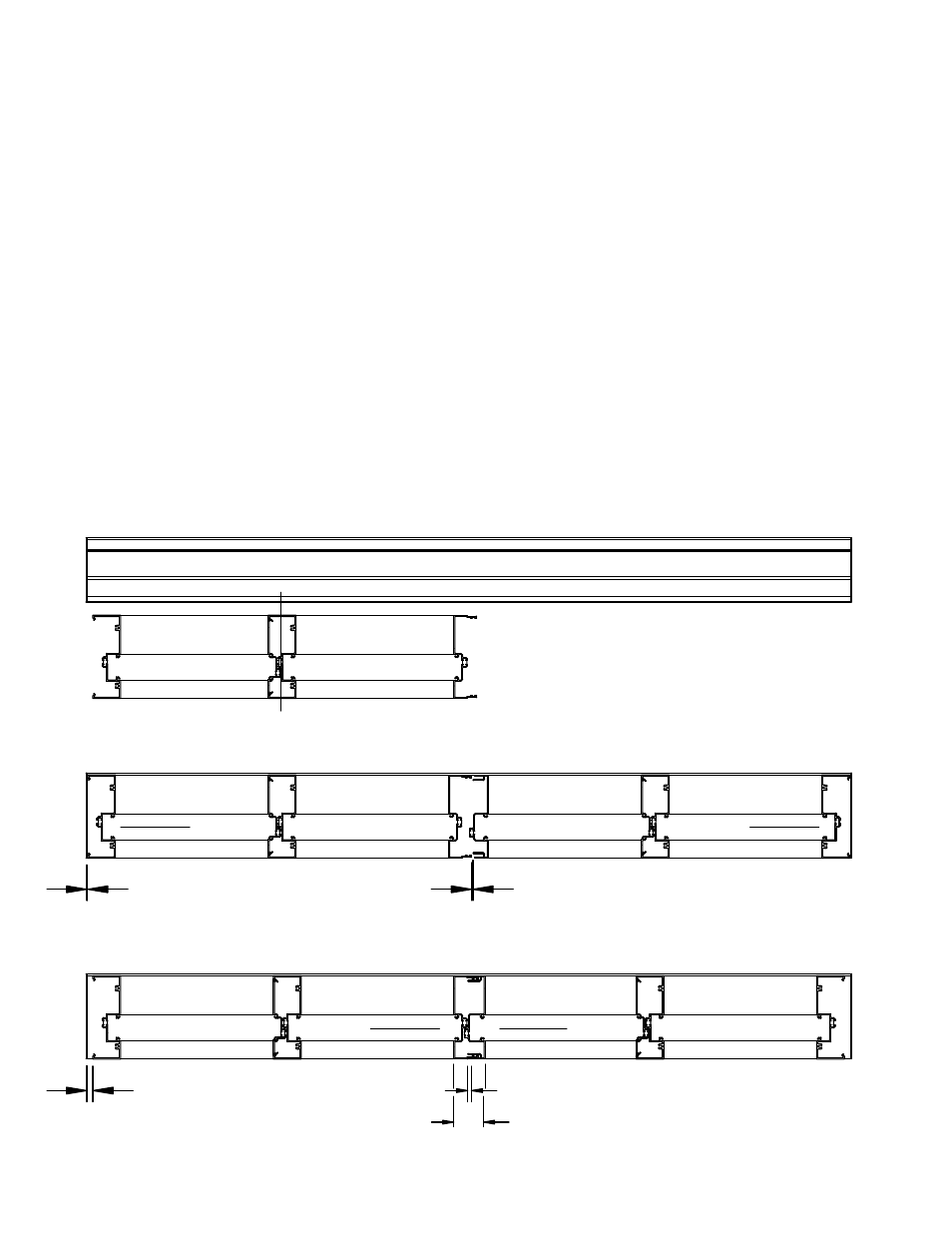

EXPANSION MULLION INSTALLATION

7/16"

1/4"

1/16"

3/8"

3/8"

The example below shows installation of the center

set system, options for front or back set are also

available. Please reference price catalog for specific

extrusions and anchors required for your installation.

Please note the locations of various seals and insure

proper locations of these seals when installing typical

runs and expansion sections of each of these

systems. These seals are shown in the sub-sill

installation and assembly sections of this manual.

The sub-sills for these products are designed so

that sill anchors may be properly sealed prior to

frame installation. The frame is either installed over

the hook-in anchors or dropped into the sill receptor.

This prevents any additional fasteners from

penetrating the sill and potentially causing leaks

from under the sill. Be sure to properly cap seal all sill

anchors prior to beginning installation of frames.

Multiple units may require the use of an expansion

mullion if total run exceeds 24 feet in length. When

elevation exceeds the 24 foot limit, locate thermal

mullions at a distance of no more than every 20 feet.

Locate splice in sub-sill at a distance of no more than

every 12 feet. A minimum of 7/16" clearance between

the jamb and sill end dam must be provided at each

end of units when using expansion mullions. This will

allow the minimum 3/8" clearance to move the units

sideways so that the second unit may be rotated into

position and interlocked into first unit. Once in

position units should be centered into opening to

provide equal joints at the jambs. Oldcastle

BuildingEnvelope recommends the use of the

FG-6188 PVC filler in the jambs and head to improve

the perimeter seal.

1/4"

2 1/4"

TM