16_glazing_guidelines_ig – Oldcastle BuildingEnvelope 6000 Series Thermal MultiPlane User Manual

Page 17

16

S E R I E S 6 0 0 0 T H E R M A L M U L T I P L A N E I N S T A L L A T I O N M A N U A L

INSIDE GLAZING GUIDELINES

1. Remove gaskets from roll and allow to relax overnight. All gaskets to be cut per sizing on page

4 plus 3/8" per foot.

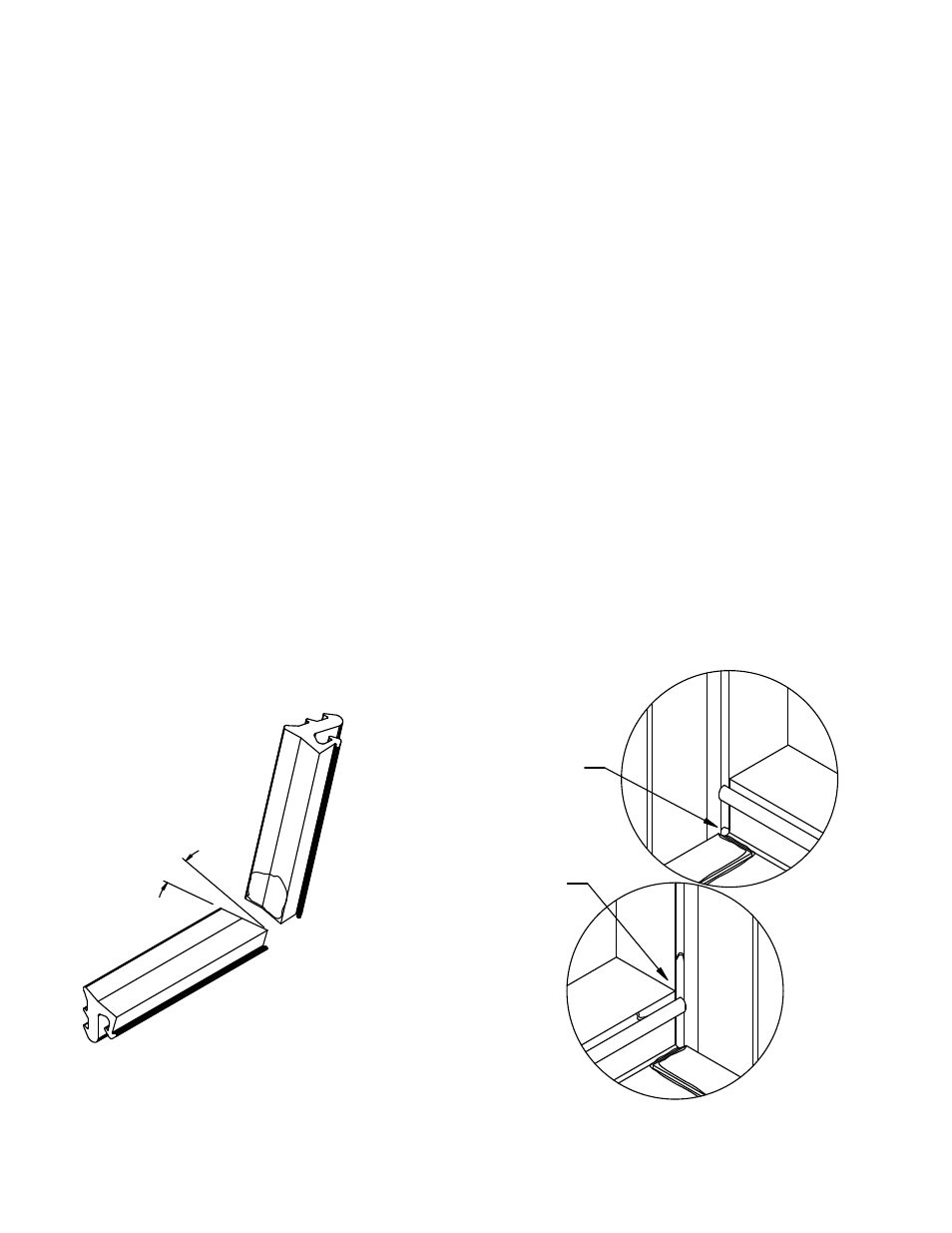

2. Vertical gaskets run through horizontal gaskets. Horizontal gaskets should be mitered on ends

as shown in Detail "A".

3. Install exterior gaskets prior to glazing. Corners of exterior gaskets to be set in sealant (Detail

"B) and sealed just prior to setting glass (Detail "A"). NOTE: Clean gaskets and surfaces with

isopropyl alcohol prior to sealing corners.

4. Locate setting blocks at either 1/4 points or 1/8 points, dependent on the size of the glass.

5. Glass bite at typical members is 7/16". At SSG verticals glass bite is 3/4".

6. Glaze openings from bottom to top. Install water diverters in horizontal above after lite below is

in position.

7. Water diverters (FG-1000-FP-2) must be located on each end of horizontals and set in sealant.

8. When installing glass, first wet the top of the setting blocks with soapy water. Once glass is set

in place, push glass against interior gasket at the setting block locations. Failure to do so may cause

diagonal cracks towards setting blocks due to glass bending while installing the gaskets in the

corners.

15°

DETAIL "A"

DETAIL "B"

Seal corners at

glazing track prior

to setting glass

Seal corner gasket

race at water diverter

Miter horizontal gasket

to vertical gasket