Hardware, Blade carrier removal, Warning – Modern AG 10' Predator User Manual

Page 49

10' Predatorrr - 49

MAInTenAnce secTIon

BLADe ReMovAL

to removed blades for sharpening or replacement, remove the cover plate on deck of cutter near

each gearbox. Remove locknut from blade bolt. Inspect lock nut after removal and replace if threads

or nylon insert are damaged. always replace nut when replacing bolt. When installing blades, be

sure to check blade bolt pivot diameter for wear. Replace bolt if worn more than 1/4 at any point.

Install blade bolts with worn side of bolt away from the center of the blade carrier. tighten lock nut

to 300 ft. lbs.

avoid personal injury. Blade and/or bade carrier removal should be done only with the tractor

engine shut off, key removed, in neutral, parking brake on, PtO disengaged, and the cutter blocked

in the raised position. avoid personal injury. Do not work under cutter without support blocks to

keep frame from falling.

BLADe cARRIeR ReMovAL

Remove cotter pin and loosen slotted nut on gear box shaft. Loosen but do not remove the nut

until the blade carrier is loosened. use a suitable two-jaw gear puller to pull carrier tapered gear box

shaft. If gear puller is not available use long bar inserted through blade bolt access hole with end

against rotor bar. Strike opposite end of bar with sledge hammer. Rotate blade carrier 180 degrees

and repeat process.

HARDwARe

Check nuts, bolts, and other miscellaneous

hardware regularly. Loose hardware is easily

lost, cause increased wear on parts, and increase

the chance of breakdown. Loose hardware creates

potential hazards which could result in personal

injury to the operator, support personnel and

bystanders. use the “torque Chart” below when

tightening bolted connections.

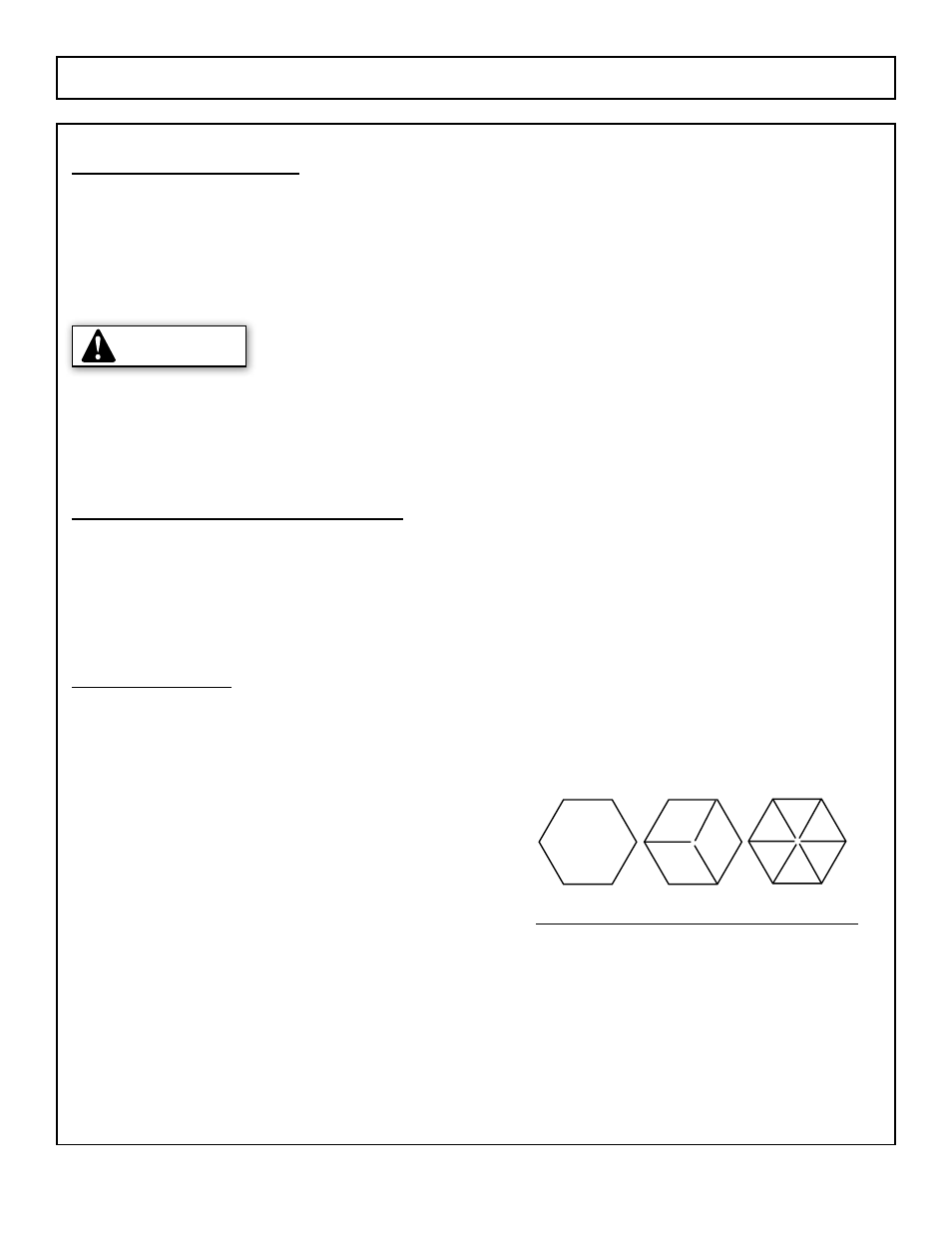

BoLT

pLAIn

THRee

sIx

DIAMeTeR HeAD

DAsHes

DAsHes

1/4 . . . . . not used . . . . . . . 10 (14) . . . . . . . . . .14 (19)

5/16 . . . not used . . . . . . . .20(27) . . . . . . . . . . 30(41)

3/8 . . . . not used . . . . . . . .35(47) . . . . . . . . . . 50(68)

7/16 . . . . . .35(47) . . . . . . . .55(75) . . . . . . . . . 80(108)

1/2 . . . . . . . .55(75) . . . . . . 85(115) . . . . . . . . 120(163)

9/16 . . . . 75(102) . . . . . 130(176) . . . . . . . . 175(237)

5/8 . . . . . 105(142) . . . . . 170(230) . . . . . . . . 240(325)

3/4 . . . . . 185(2510 . . . . . 300(407) . . . . . . . . 425(576)

7/8 . . . . . 160(217) . . . . . 445(603) . . . . . . . . 685(929)

1 . . . . . . 250(339) . . . . . 670(906) . . . . . . 1030(1396)

1 1/8 . . . 330(447) . . . . 910(1234) . . . . . . 1460(1979)

1 1/4 . . . 480(651) . . . 1250(1695) . . . . . . 2060(2793)

2 (B)

5 (D)

8 (F)

RecoMMenDeD ToRQue

In FT-LBs (nM)

coARse AnD FIne THReADs

wARnInG