Driveline attachment, Danger – Modern AG 10' Predator User Manual

Page 29

10' Predatorrr - 29

opeRATIon secTIon

DRIveLIne ATTAcHMenT

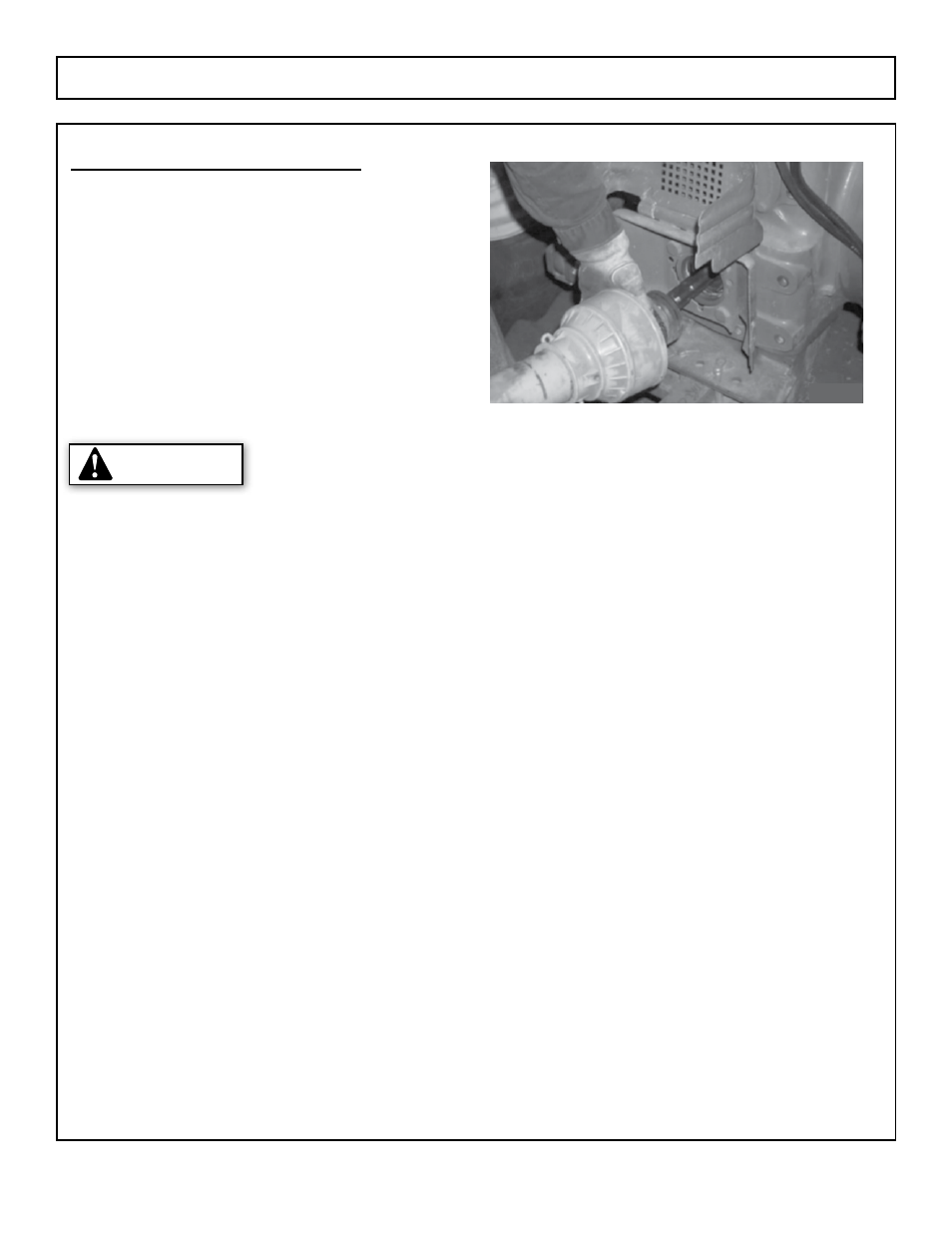

the driveline yoke and tractor PtO shaft must be

dirt free and greased for attachment.

to connect the cutter driveline to the tractor PtO

output shaft, pull the driveline yoke collar back and

align the grooves and splines of the yoke with those

of the PtO shaft. Push the driveline yoke onto the

PtO shaft, release the locking collar, and position

the yoke until the locking collar balls are seated

onto the PtO shaft. Push and pull the driveline

back and forth several times to ensure a secure

attachment.

When attaching the Implement input driveline to the tractor PtO, it is important that the connecting

yoke spring activated locking collar slides freely and the locking balls are seated securely in the groove

on the tractor PtO shaft. a driveline not attached correctly to the tractor PtO shaft could come loose

and result in personal injury and damage to the implement.

the operator’s manual and decals affixed on the unit contain important instructions on the safe

and proper use of the equipment. maintain these important safety features on the implement in

good condition to ensure the information is available to the operator at all times.

• ensure the manual canister is secured to the equipment with the operator’s manual inside.

• ensure all decals are in place and legible. Replace missing, damaged, and illegible decals.

• ensure the cutter hitch is securely attached to the tractor drawbar with a proper size bolt

and secured nut.

• ensure chain guards and/or rubber deflectors are in position and not damaged. Replace

worn, broken, and missing sections immediately.

• ensure the driveline integral shields are in good condition and rotate freely.

• Inspect that all bolts and screws are in position and are properly torqued.

• ensure the tractor PtO master shield is in place, lowered and in good condition.

• ensure each cutter slip clutch shield is secured in place and in good condition.

• Inspect each gearbox oil level and replenish if needed. a low oil level is a warning sign that the

gearbox may be cracked or its seal is damaged and needs to be replaced.

• ensure all gearbox vents are in place and free from clogs.

• Inspect blades and blade bolts for looseness and excessive wear. make sure the cutter is

securely blocked up before crawling beneath. Replace damaged, worn, and missing blades

as complete sets to maintain rotary balance.

• ensure carrier hub nuts are tightened with the cotter pin inserted and spread.

DAnGeR