Losi LOSB0217 Manual User Manual

Page 7

Page 7

Ride Height

This is the height the chassis sits and runs at. Turning the shock collar clockwise, looking down from the top, will

increase the pre-load on the spring and raise the chassis. You may want to try this when running on extremely

rough surfaces.

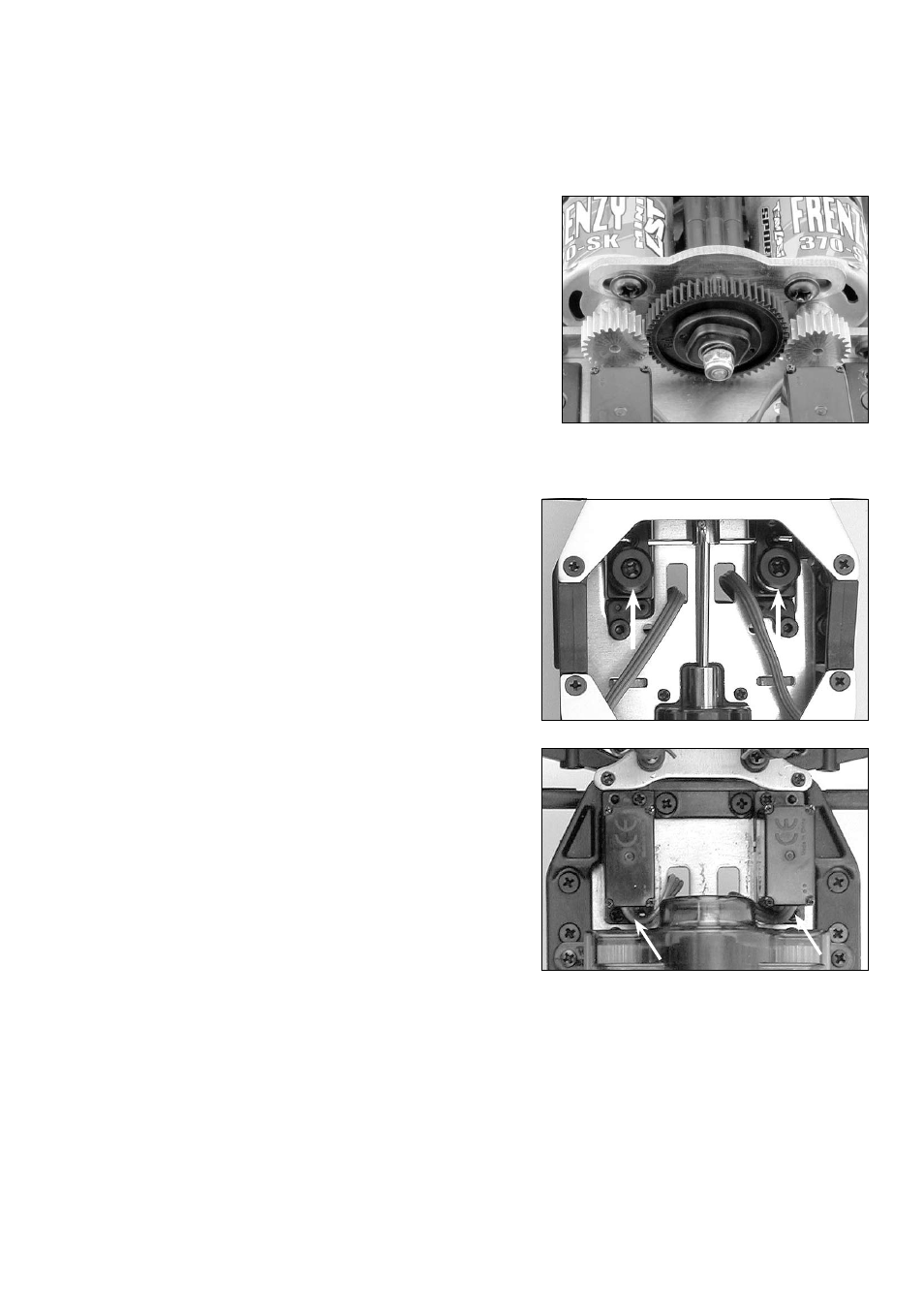

Changing the Spur Gear

If you are changing the size of the spur gear and/or pinion gears, you

will have to loosen the four screws that attach the motors (two screws

on each motor) to the motor plate and follow the directions for adjusting

the gear mesh.

1. Remove the gear cover. Use the included wrench to remove the

slipper adjustment nut by turning it counterclockwise.

2. Remove the old spur gear and install the new one of the same size.

3. Replace the slipper plate, washers and nut. See “Adjusting the

Slipper” for proper adjustment directions.

Replacing a Steering Servo

1. Locate and disconnect the servo lead where it plugs in the

receiver harness. There will be two of these, one for the left

servo and one for the right servo.

2. Turn the Mini-LST2 upside-down and with the wheels pointing

straight forward, remove the Phillips screw from the center of

the servo arm (Figure 1). Set the screw, washer and spring to

one side and remove the bell crank.

3. Turn the Mini-LST2 over, remove the small screws at the front

and back of the servo (Figure 2). Carefully remove the servo

feeding the servo lead through the chassis noting the proper

routing for the new servo lead.

4. Install the new servo connecting and routing the wires like the

one you removed. Secure the servo with the screws at the

front and rear.

5. Turn on the radio and remove the servo saver bottom from the

removed servo and install it on the new servo so that the “V-

Groove” is pointing toward the other servo.

6. Reinstall the bell crank, spring, and washer, securing them

with the Phillips screw.

Changing the Pinion Gear/Gear Ratio

You must always use the same spec of motor and size of pinion gear on both motors in the Mini-LST2. When you

install hotter motors you may find it necessary to install smaller pinion gears to keep them from overheating. This is

usually caused when you are running in a confined area where the motors are not allowed to rev freely. At this point

both motors should be slightly loose on the motor plate.

1. Use the small Allen wrench included to loosen the setscrews in both pinion gears. Slide off the pinions and

replace them with the new size. If the new pinions do not slide on to line up with the spur gear, pull the motors

away from the spur for more clearance.

2. When aligned properly with the spur gear, tighten the setscrew on each pinion.

3. While looking closely at the teeth of the spur gear and one pinion push the motor toward the spur gear until you

can see they are just starting to mesh and slightly snug the mounting screws for that motor. Repeat this for the

other motor as well.