Dynojet 250: Torque Module User Manual

Page 25

T H E TO R Q U E M O D U L E A N D W I N P E P 6

Torque Module Calibration

Version 4

Torque Module Installation and User Guide for Model 250 Dynamometers

A-3

3

Select Options

Calibrate.

Note: Before proceeding, be sure the eddy current brake is free and clear of any

obstructions. There should not be anything resting on the eddy current brake or

the dynamometer drum during this procedure.

4

Enter the Torque Module calibration value.

4a

Enter the calibration number stamped on the calibration arm extension. If

you do not have enough room to install the extension, use the number

stamped on the main bar.

Note: Dynojet recommends you use the calibration arm with the extension unless

space constraints in your dyno room do not allow you to.

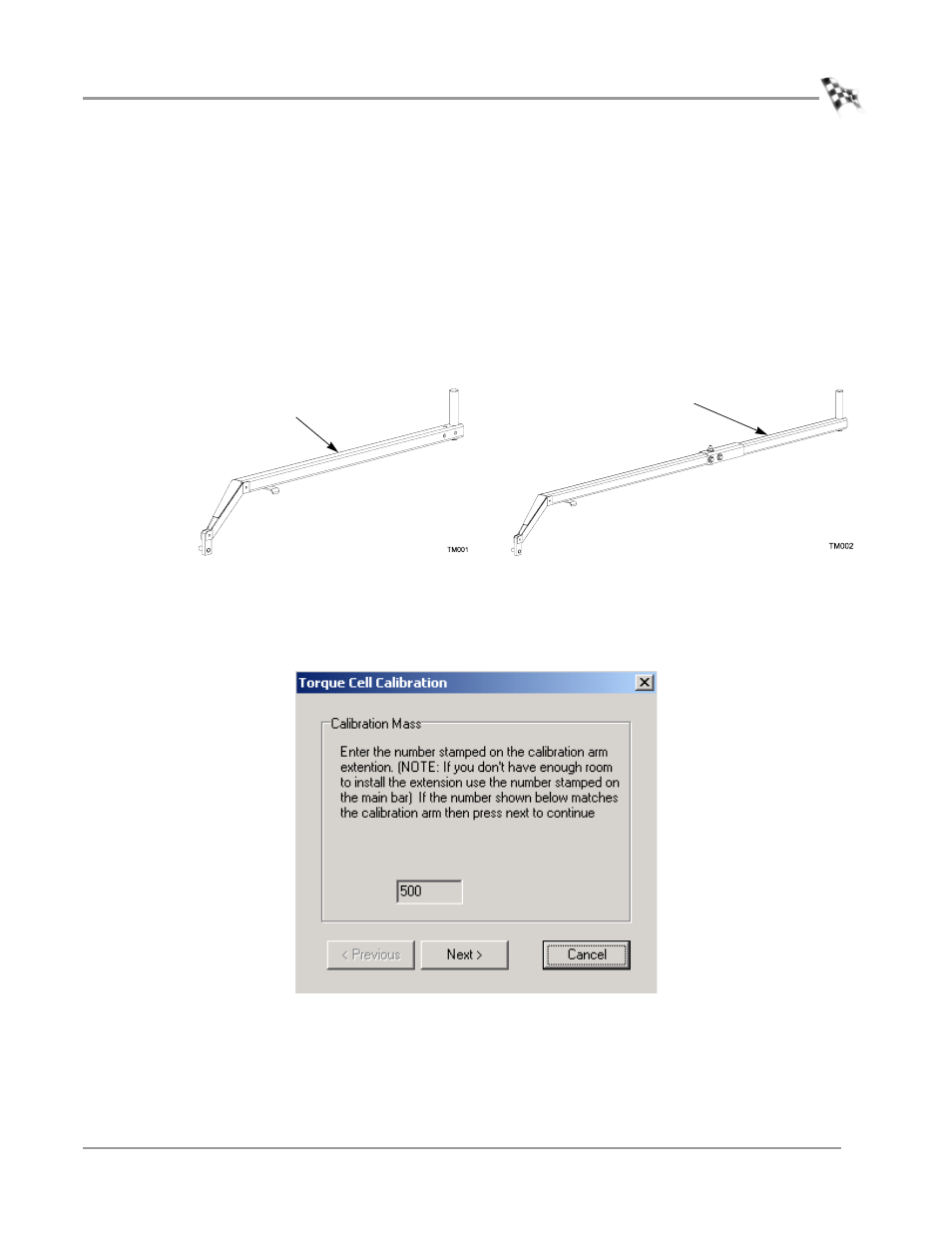

Figure A-3: Calibration Arm

Note: Follow the directions on the screen exactly. Failure to perform the

directions accurately will result in improper torque values.

5

Click Next to continue.

Figure A-4: Calibration Mass Window

calibration arm

main bar

calibration arm with

extension

- 150: Kart and ATV Dynamometers (44 pages)

- 150: Dyno Drum Cover for Kart and ATV Dyno Motorcycle Option (3 pages)

- 150: WinPEP 7 (170 pages)

- 168: Eddy Current Brake (27 pages)

- 200: Eddy Current Brake (45 pages)

- 200: Replacing the Starter Ring Gear (7 pages)

- 200: Safety Switch (3 pages)

- 200: DynoWare EX+ Upgrade Installation Guide for Motorcycle Dynos (20 pages)

- 200: Throttle Stop (3 pages)

- 200: Eddy Current Brake Driveline Upgrade (17 pages)

- 200i: High Pressure Blower (20 pages)

- 200: Installation Guide (73 pages)

- 200i: Pit Installation Guide (154 pages)

- 200i: Pre-Installation Guide (52 pages)

- 200i: Installation Guide (184 pages)

- 200i: Air Brake and EEC Kit (40 pages)

- 200i: Dynamometer Wiring Schematic (2 pages)

- 200i: Folding Ramp (15 pages)

- 200i: Control Panel Interface Upgrade (S/N 201xxxx) (31 pages)

- 200i: Control Panel Interface Upgrade (S/N 202xxxx) (29 pages)

- 200i: Motorcycle Exhaust Extraction System Drawings (18 pages)

- 200iP: Pit Installation Guide (148 pages)

- 200iPX: Installation Guide (52 pages)

- 200iPX: Installation Guide (163 pages)

- 200ix: Pit Installation Guide (163 pages)

- 200ix: Extended Carriage and Trike Adapter Assembly (15 pages)

- 200iX: Upgrade Installation Guide (56 pages)

- 200ix: Extended Carriage with Trike Adapter Assembly (13 pages)

- 224: CE Package (17 pages)

- 224: Maintenance Guide (35 pages)

- 224: Installation Guide (78 pages)

- 224/4WD: Installation Guide (77 pages)

- 224: Pit Installation Guide (56 pages)

- 224x: Above Ground Four Post Lift Dimensions (1 page)

- 224x: Pre-Installation Guide (63 pages)

- 224x: 4WD Dyno Air and Wiring Schematic (2 pages)

- 224: Eddy Current Brake (73 pages)

- 224: Pit Eddy Current Brake (69 pages)

- 224xLC2: Quickstart guide for DWRT (2 pages)

- 248: Pit Installation Guide (74 pages)

- 248: Installation Guide (58 pages)

- 248: DynoTRAC User Guide with Variable Brake (14 pages)

- 248: DynoWare EX+ Upgrade (22 pages)

- 248: Optical RPM Sensor (22 pages)

- 248: Proportional Air Brake (21 pages)