Warning – Code 3 Stop/Turn/Tail User Manual

Page 4

CONNECTION TABLE

FUNCTION

RED

WHITE

BLACK (GROUND, EARTH)

STOP

X

X

TAIL

X

X

TURN

X

X

REVERSE

X

X

4

8.

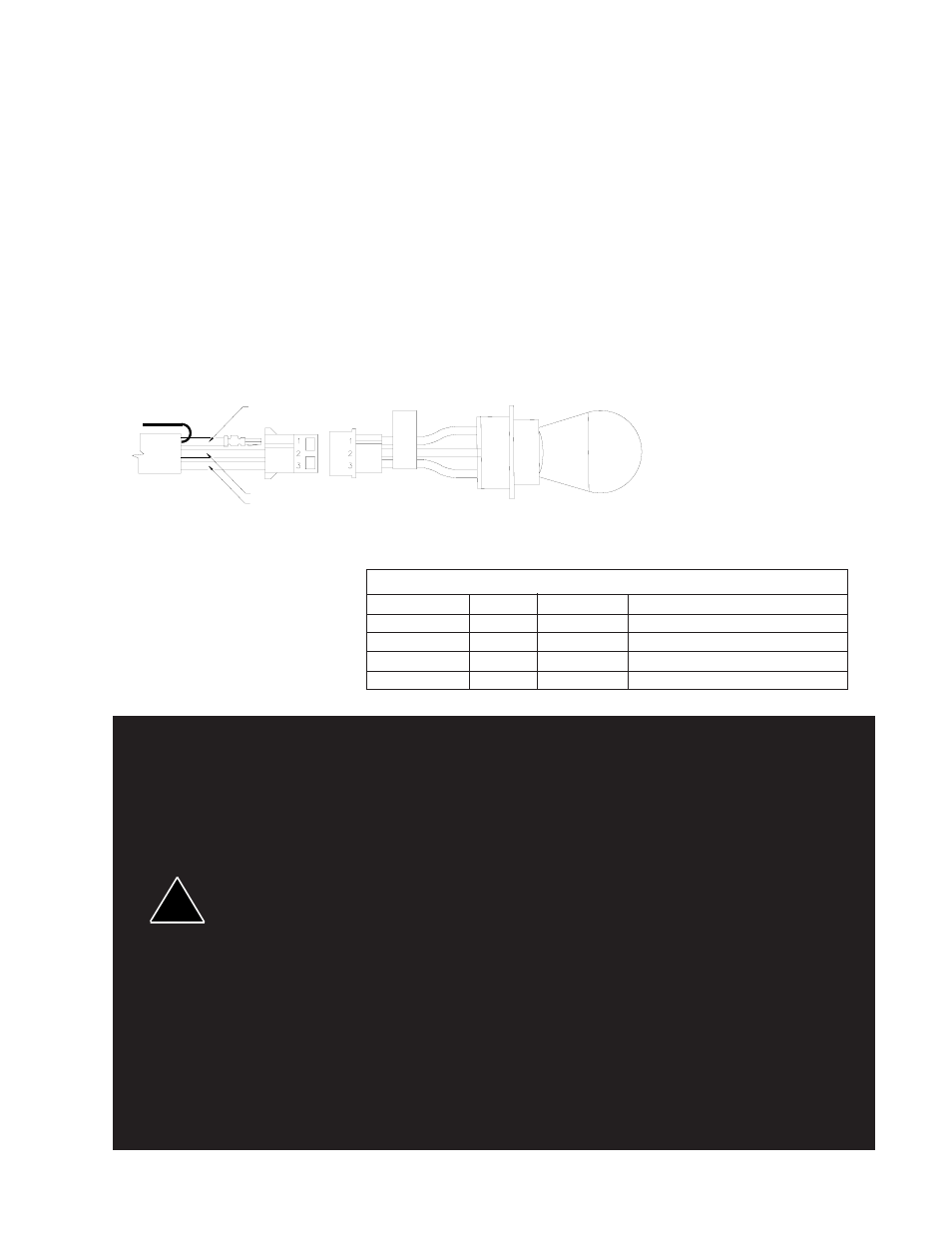

Use the connection diagram in Figure 4 to connect the wiring for the light application.

9.

Test each light function by connecting the dual filament lamp assembly to the cable before final

installation.

10. Route the assembled cable with the AMP Mate-N-Lock connectors through the reflector. Connect the dual

filament lamp to the cable. Align the largest flange of the dual filament socket with the largest cut-out on

the reflector. Press and twist clockwise 1/8 turn to secure the lamp in the reflector.

11. Verify the “TOP” lens engraving is facing upward. Mount the reflector assembly and lens by installing

the four screws.

Larger wires and tight connections will provide longer service life for components. For high

current wires it is highly recommended that terminal blocks or soldered connections be used

with shrink tubing to protect the connections. Do not use insulation displacement connectors

(e.g. 3M

®

Scotchlock type connectors). Route wiring using grommets and sealant when

passing through compartment walls. Minimize the number of splices to reduce voltage drop.

High ambient temperatures (e.g. underhood) will significantly reduce the current carrying

capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in engine compartment.

All wiring should conform to the minimum wire size and other recommendations of the

manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable

ties, and similar installation hardware should be used to anchor and protect all wiring.

Fuses or circuit breakers should be located as close to the power takeoff points as possible

and properly sized to protect the wiring and devices.

Particular attention should be paid to the location and method of making electrical connections

and splices to protect these points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably

directly to the vehicle battery.

The user should install a fuse sized to approximately 125% of the maximum Amp capacity

in the supply line to protect against short circuits. For example, a 30 Amp fuse should carry

a maximum of 24 Amps.

DO NOT USE 1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR

CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS.

Circuit breakers are very sensitive to high temperatures and will "false trip" when mounted

in hot environments or operated close to their capacity.

!

WARNING!

For 41 series models with optional bezel, snap the reflector into the bezel making sure the reflector's

"TOP" aligns with the bezel's 7023 product number.

SHIELD WIRE

(CUT FLUSH)

RED WIRE

BLACK WIRE (GROUND, EARTH)

WHITE WIRE

FIGURE 4