Model number nomenclature, Quality assurance – Carrier 30XW325-400 User Manual

Page 5

5

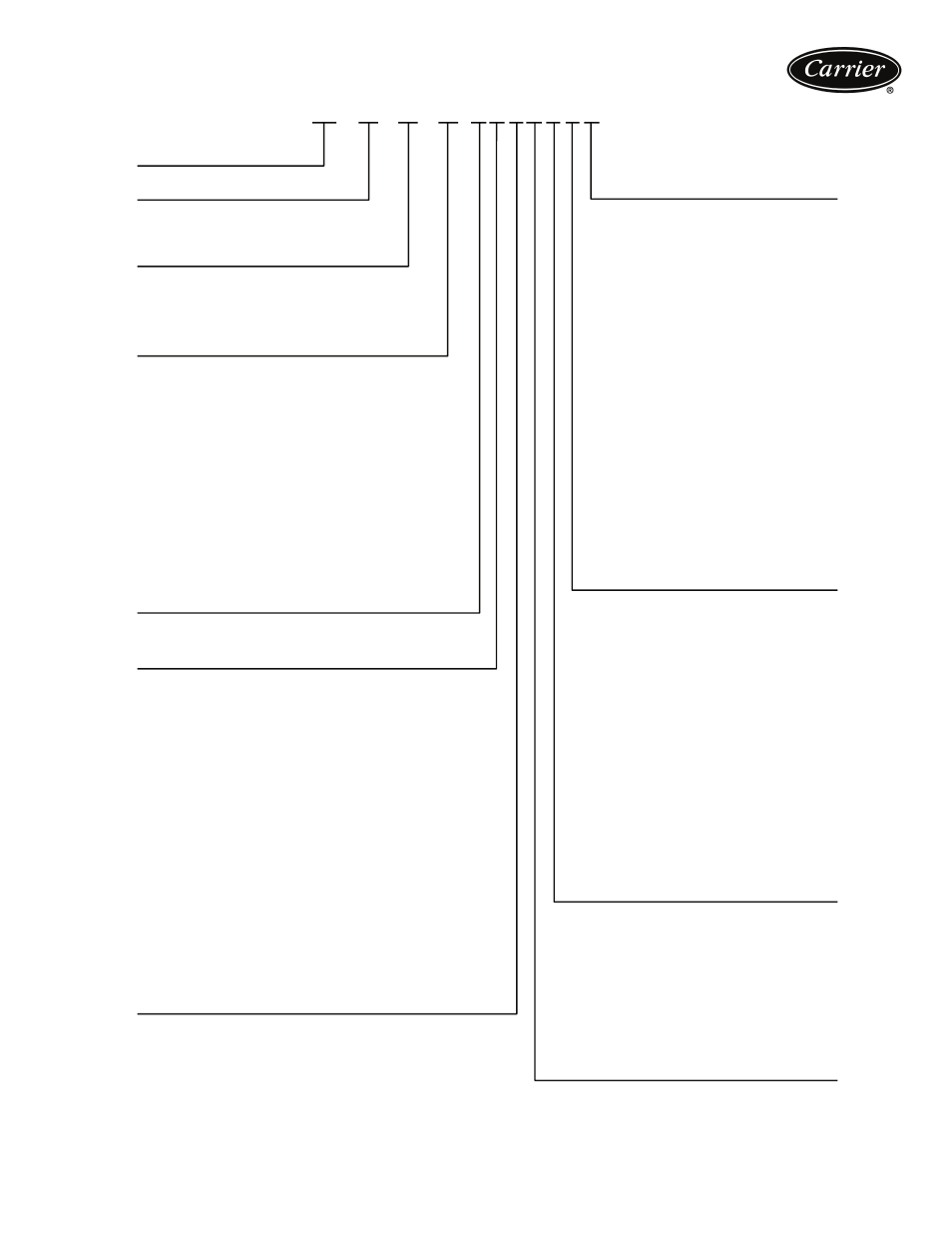

Model number nomenclature

a30-4744

30XW – 325 6 –

–

–

4

–

3 B

30XW – AquaForce

®

Water-Cooled

Screw Chiller

Design Series

Unit Size (Nominal Tons) (kW)

325 – 325 (1133)

350 – 350 (1206)

400 – 400 (1354)

Voltage

1 – 575-3-60

2 – 380-3-60

4 – 230-3-60

6 – 460-3-60

7 – 200-3-60

Condenser Options

- – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Discharge Connections (Std)

0 – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Suction Connections

1 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Connections

2 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Connections

3 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Discharge Connections

4 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Suction Connections

5 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Connections

6 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Suction Connections

7 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Discharge Connections

8 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Suction Connections

9 – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Discharge Connections

B – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Suction Connections

C – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Connections

D – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Suction Connections

F – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Connections

G – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Suction Connections

H – 1 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

J – 1 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

K – 1 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

L – 1 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Leaving

Heat Machine

- – Std Condenser/Comfort Cooling (Std)

M – Heat Machine Condenser/Comfort Cooling

Evaporator Options

- – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Discharge Connections (Std)

0 – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Suction Connections

1 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Connections

2 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Connections

3 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Discharge Connections

4 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Suction Connections

5 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Connections

6 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Suction Connections

7 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Discharge Connections

8 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Suction Connections

9 – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Discharge Connections

B – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Suction Connections

C – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Connections

D – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Suction Connections

F – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Connections

G – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Suction Connections

H – 1 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

J – 1 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

K – 1 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

L – 1 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Leaving

M – 3 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

N – 3 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Leaving

P – 3 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

Q – 3 Pass, NIH, 300 psig (2068 kPa), Flange, Suction Leaving

R – 3 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

S – 3 Pass, MWB, 150 psig (1034 kPa), Flange, Suction Leaving

T – 3 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Leaving

V – 3 Pass, MWB, 300 psig (2068 kPa), Flange, Suction Leaving

Packaging/Charging Options

B – R-134a Refrigerant with Bag (Std)

C – R-134a Refrigerant with Crate Over Bag

D – Nitrogen Refrigerant with Bag

F – Nitrogen Refrigerant with Crate Over Bag

Controls/Communications Options

- – Navigator™ Display

0 – Navigator Display, EMM

1 – Navigator Display, GFCI Service Option

2 – Navigator Display, EMM, GFCI Service Option

3 – Touch Pilot™ Display (Std)

4 – Touch Pilot, EMM

5 – Touch Pilot, GFCI Service Option

6 – Touch Pilot, EMM, GFCI Service Option

7 – Navigator Display, BACnet™ Translator

8 – Navigator Display, EMM, BACnet Translator

9 – Navigator Display, GFCI Service Option,

BACnet

Translator

B – Navigator Display, EMM, GFCI Service Option,

BACnet

Translator

C – Touch Pilot Display (Std), BACnet Translator

D – Touch Pilot Display, EMM, BACnet Translator

F – Touch Pilot Display, GFCI Service Option,

BACnet

Translator

G – Touch Pilot Display, EMM, GFCI Service Option,

BACnet

Translator

H – Navigator Display, LON Translator

J – Navigator Display, EMM, LON Translator

K – Navigator Display, GFCI Service Option,

LON

Translator

L – Navigator Display, EMM, GFCI Service Option,

LON

Translator

M – Touch Pilot Display (Std), LON Translator

N – Touch Pilot Display, EMM, LON Translator

P – Touch Pilot Display, GFCI Service Option,

LON

Translator

Q – Touch Pilot Display, EMM, GFCI Service

Option,

LON

Translator

Electrical Options

- – Single Point, XL Starter, Terminal Block

(Std 380, 460, 575-v)

0 – Single Point, Wye-Delta Starter, Terminal

Block

(Std 200,230-v)

3 – Dual Point, XL Starter, Terminal Block

4 – Dual Point, Wye-Delta Starter, Terminal Block

7 – Single Point, XL Starter, Non-Fused Disconnect

8 – Single Point, Wye-Delta, Non-Fused Disconnect

C – Dual Point, XL Starter, Non-Fused Disconnect

D – Dual Point, Wye-Delta Starter, Non-Fused

Disconnect

H – Single Point, XL Starter, Terminal Block, CPT

J – Single Point, Wye-Delta Starter, Terminal

Block,

CPT

M – Dual Point, XL Starter, Terminal Block, CPT

N – Dual Point, Wye-Delta Starter, Terminal

Block,

CPT

R – Single Point, XL Starter, Non-Fused

Disconnect, CPT

S – Single Point, Wye-Delta, Non-Fused

Disconnect, CPT

W – Dual Point, XL Starter, Non-Fused

Disconnect, CPT

X – Dual Point, Wye-Delta Starter, Non-Fused

Disconnect, CPT

Refrigeration Circuit Options

*

4 – Standard Unit

6 – With Suction Service Valves

D – With Minimum Load Control

G – With Suction Service Valves and Minimum

Load Control

N – With Condenser Insulation for Heat Machine

Q – With Suction Service Valves and Condenser

Insulation for Heat Machine

X – With Minimum Load Control and Condenser

Insulation for Heat Machine

Z – With Suction Service Valves, Minimum Load

Control

and Condenser Insulation for

Heat Machine

LEGEND

*Evaporator insulation is standard.

Quality Assurance

Certified to ISO 9001:2000

CPT

— Control Power Transformer

MWB — Marine Waterbox

EMM

— Energy Management Module

NIH

— Nozzle-In-Head

GFCI

— Ground Fault Circuit Interrupter

XL

— Across-the-Line Start

LON

— Local Operating Network