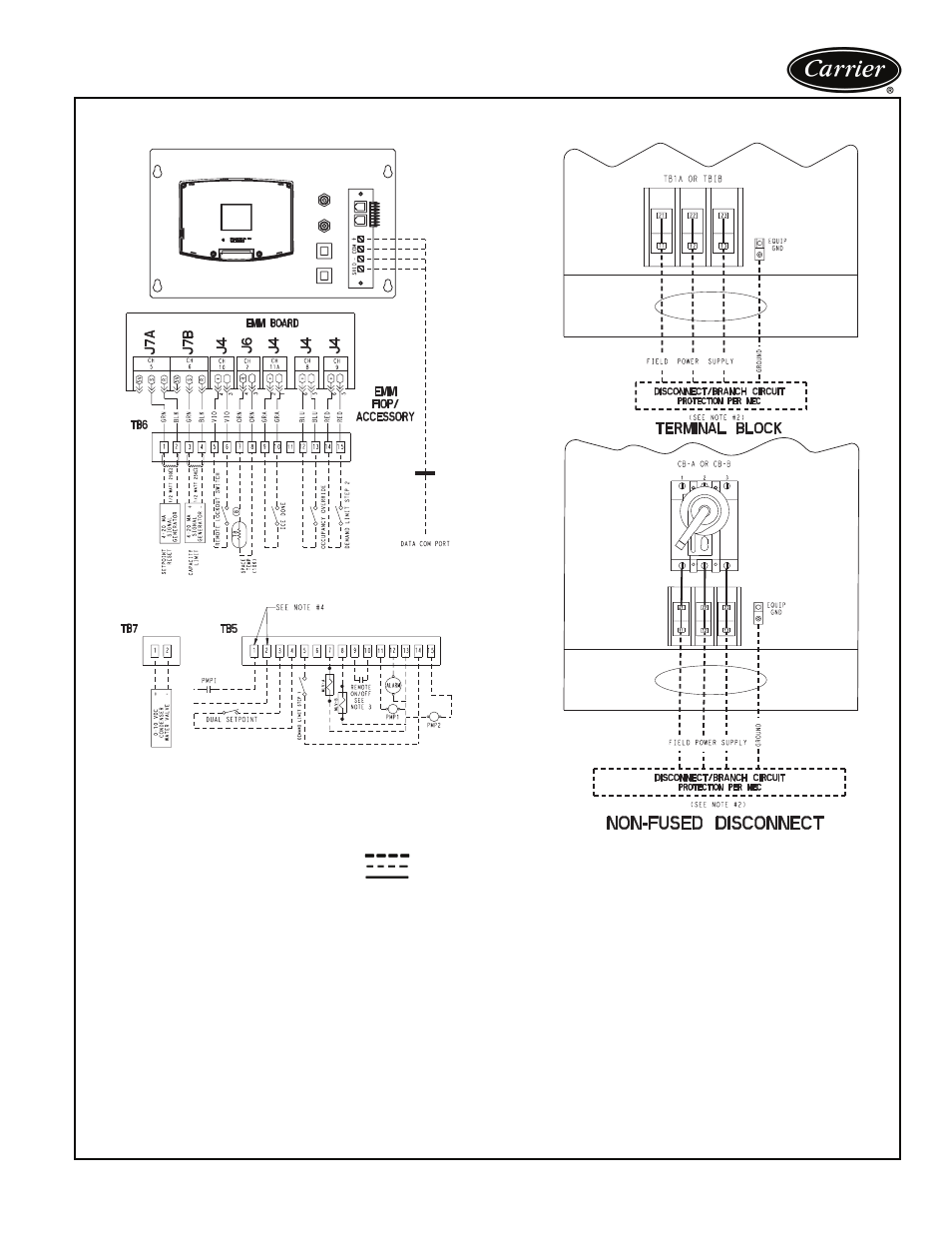

Typical control wiring schematics – Carrier 30XW325-400 User Manual

Page 21

21

Typical control wiring schematics

30XW UNIT CONTROL WIRING SCHEMATIC

LEGEND

AWG

— American Wire Gage

NEC

— National Electrical Code

CB

— Circuit Breaker

PMP

— Chilled Water Pump

COM

— Communication Port

PMPI

— Chilled Water Pump Interlock

EMM

— Energy Management Module

TB

— Terminal Block

EQUIP GND

— Equipment Ground

Field Power Wiring

FIOP

— Factory-Installed Option

Field Control Wiring

MLV

— Minimum Load Valve

Factory-Installed Wiring

NOTES:

1. Factory wiring is in accordance with UL 1995 standards. Field modifica-

tions or additions must be in compliance with all applicable codes.

2. Wiring for main field supply must be rated 75C minimum. Use copper for

all units. Incoming wire size range for the terminal block is #4 AWG to

500 kcmil for single point power (two conductors per phase). Incoming

wire size range for the terminal blocks for dual point power option is

#4 AWG to 500 kcmil for single point power (one conductor per phase).

Incoming wire size range for 200/300-v models is 3/0 to 500 kcmil for sin-

gle point power (one conductor per phase).

3. Terminals 9 and 10 of TB5 are for field external connections for remote

on-off. The contacts must be rated for dry circuit application capable of

handling a 24-vac load up to 50 mA.

4. Terminals 1 and 2 of TB5 are for external connections of chilled water

pump interlock. The contacts must be rated for dry circuit application

capable of handling a 24-vac load up to 50 mA.

5. Terminals 11 and 13 of TB5 are for control of chilled water pump 1

(PMP 1) starter. Terminals 15 and 13 of TB5 are for control of chilled

water pump 2 (PMP 2) starter. Remove factory-installed jumper when

using pump interlock. The maximum load allowed for the chilled water

pump relay is 5-va sealed, 10-va inrush at 24-v. Field power supply is not

required.

6. For control of chilled water pumps, a set of normally open contacts rated

for dry circuit application must be supplied from field-supplied pump

starter relay. Connect contacts directly to connector at main base board

channel 18.

7. Terminals 12 and 13 of TB5 are for an alarm relay. The maximum load

allowed for the alarm relay is 10-va sealed, 25-va inrush at 24-v. Field

power supply is not required.

8. Make appropriate connections to TB6 as shown for energy management

board options. The contacts for occupancy override, demand limit, and

ice done options must be rated for dry circuit application capable for han-

dling a 24-vac load up to 50 mA.

9. Terminal blocks TB5 and TB6 are located in the display panel box for all

units. Refer to certified dimensional drawing for each unit to get the exact

locations.

10. Refer to certified dimensional drawings for exact locations of the main

power and control power entrance locations.

11. For control of condenser pump, connect field-supplied relay (max 5-va

sealed, 10-va inrush at 24-v) directly to connector at main base board

channel 22.

12. For head pressure control option, 0-10-vdc signal wires are factory-

installed (violet and brown) from HGBP/COND board channel 9. Refer to

controls manual for application with field-supplied water regulating valve.

a30-4697