Assembly, Adjusting the carriage bearings – Craftsman 315.220380 User Manual

Page 30

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY

Loose carriage bearings permit the blade to wander

slightly while cutting, which will result in a poor cut

and more wear and tear on the saw. Use the following

steps to check for tightness and to then adjust the

bearings if needed.

■ On the left side of the arm, remove the carriage

lock knob, the carriage cover screws, and the

carriage cover.

■ With one hand, grip the front bearing hard to keep it

still, and pull the carriage forward with the other

hand. The bearing should turn. If it stays still as the

carriage is moved, it needs to be adjusted.

CARRIAGE BEARING

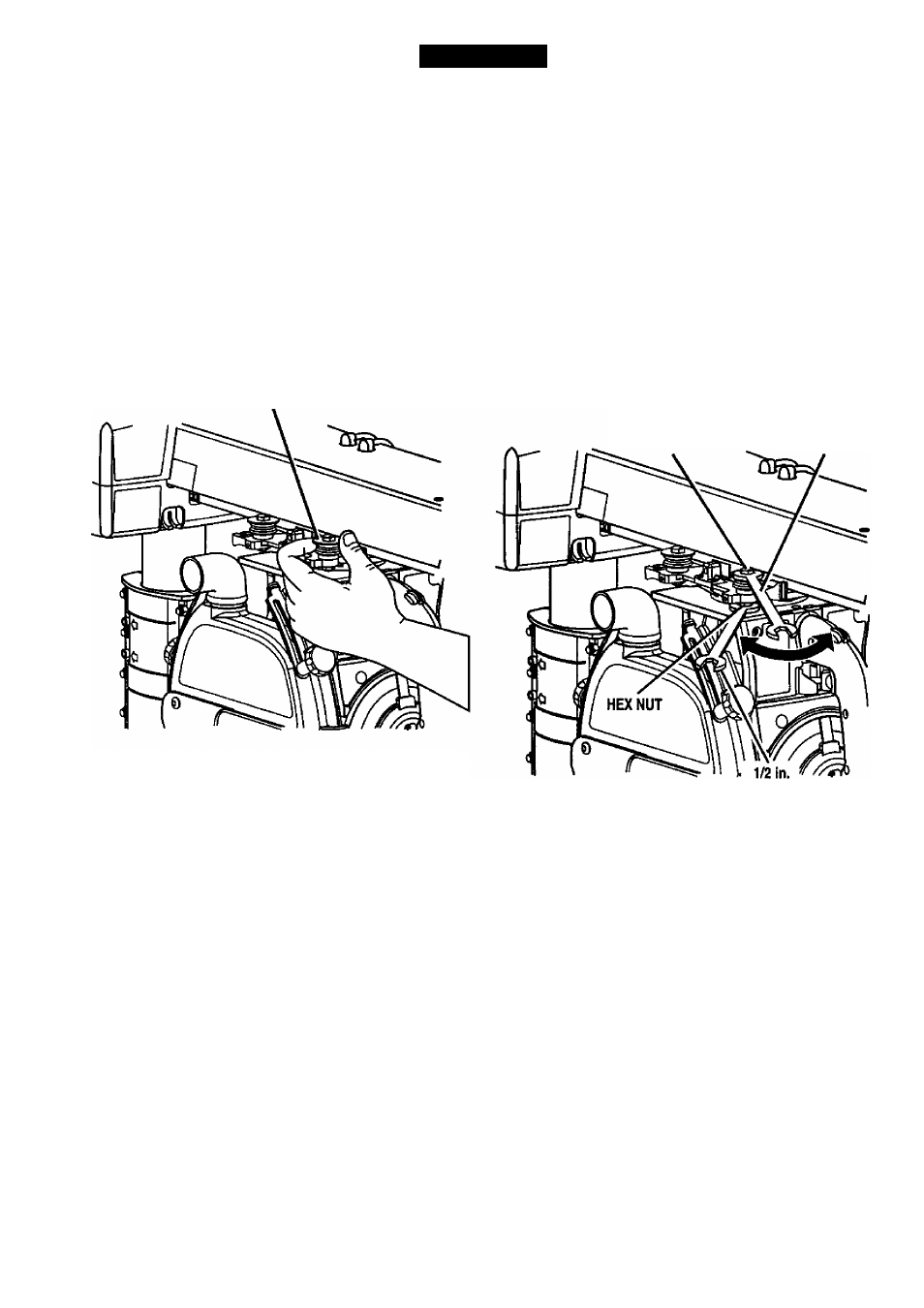

ADJUSTING THE CARRIAGE BEARINGS

See Figures 21A and21B.

■ Use a 9/16 in. wrench to hold the eccentric screw

(top of bearing) and a 1/2 in. wrench to loosen the

nut below the bearing.

■ Turn the eccentric screw a partial turn as needed to

tighten the bearing.

■ Retighten the nut and repeat the second step to

test the tightness. Adjust it so the bearing turns

even against resistance when the carriage is

moved - but not so much that the carriage is difficult

to move and return it to its rear position.

■ Repeat for the left rear bearing.

Note:

Adjust bearings on the left side only. Bearings

on the right side do not adjust.

■ Replace the carriage cover, carriage cover screws,

and carriage lock knob.

:

ECCENTRIC SCREW

9/16 In.

WRENCH

GRASP AND HOLD

CARRIAGE BEARING

Fig. 21A

WRENCH

Fig. 21B

CRRmHHN* RADIAL SAW 315.220380

30