General recomiviendations, Before each use, Motor oil – Craftsman 987.889000 User Manual

Page 24: Checking oil level, Changing oil, Engine cleaning, Customer responsibilities, 24 hgure 5-1

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER RESPONSIBILITIES

GENERAL RECOMIVIENDATIONS

The warranty on this equipment

does not cover items that have

been subjected to operator abuse

or negligence. To receive full val

ue from the warranty, the operator

must maintain the equipment as

instructed in this manual.

Some adjustments will need to be

made periodically to property

maintain your equipment.

All adjustments in the Service and

Adjustments section of this manu

al should be checked.at least

once each season.

Keep the air filters clean and

change the spark plug once a

year. A clean air filter system and

a new spark plug will help your

engine run better and last longer.

Before Each Use

• Check engine oil level.

• Check all hardware for

tightness.

• Check that all guards and

shields are in place and properly

secured.

MOTOR OIL

• Only use high quality detergent

oil rated with API sen/ice classifi

cation SF, SG or SH. Select the

oil’s SAE viscosity grade accord

ing to your expected operating

temperature. Above 32op, use

SAE 30; below 320F, use 5W30.

NOTE: Although multi-viscosity

oils (5W30,10W30 etc.) improve

starting in cold weather, these oils

will result in increased oil con

sumption when used above 320R

Check engine oil more frequently

to avoid possible engine damage

from running low on oil.

Checking Oil Level

Engine oil level must be between

"ADD" and "FULL" marks on dip

stick at all times. Check before

each use and every 5 operating

hours.

1. Park machine on level ground.

2. Stop engine, wait for parts to

stop moving, and disconnect

spark piug wire.

: '

3. Clean area around dipstick (Z,

Figure 5-1) to prevent dirt from en

tering oil fill hole.

4. Remove dipstick. Oil level must

be between “ADD” and “FULL”

marks. Do not exceed “PULL”

mark on dipstick.

5. To add oil, pour slowly into dip

stick opening. While adding,

check oil level frequently by se

curely replacing dipstick and re

moving to read oil level. Wipe dip

stick clean each time oil level is

checked.

6. After filling to “FULL” mark, se

curely replace dipstick.

Changing Oil

Change oil after the first 2 operat

ing hours and every 25 operating

hours thereafter. Change oil while

engine is still warm from recent

operation. Warm oil flows more

freely and carries away more

impurities.

1. Stop engine, wait for parts to

stop moving, and disconnect

spark piug wire.

2.

Remove dipstick (Z, Rgure 5-1).

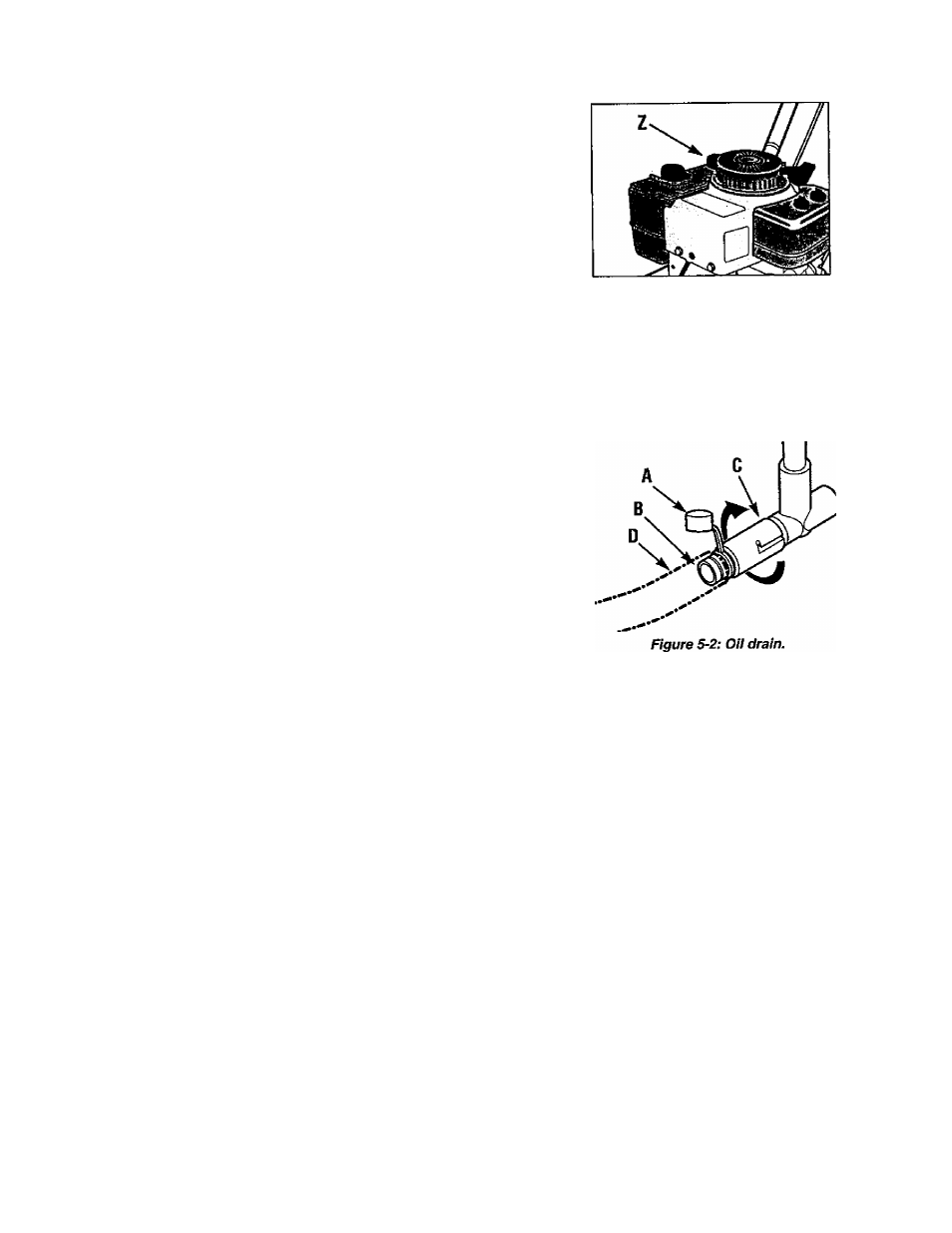

3. Remove protective cap (A, Fig

ure 5-2) to expose oil drain port

(B).

4. Push oil drain hose (D) (includ

ed in hardware bag with unit) onto

oil drain port. Route other end of

hose to an appropriate oil collec

tion receptacle.

5. Twist oil drain fixture (C) to the

open position. Pull out. Drain oil

completely.

6. Push in and twist oil drain fixture

to the closed position. Remove

drain hose. Replace protective cap

(A).

7. Refill engine with fresh oil and

securely replace dipstick.

NOTE: Please dispose of all waste

materials in an ecologically re

sponsible manner. Use proper

waste material storage containers.

24

Hgure 5-1

ENGINE CLEANING

•

Stop engine, wait for parts to

stop moving, disconnect spark

plug wire, and allow engine to

coot before inspecting or clean

ing engine.

•

Daily or more often, before run

ning engine, remove grass and

chaff from recoil finger guard or

rotating screen to prevent engine

damage caused by overheating.

Also keep cooling vanes, governor

linkage, springs and controls free

of debris.

• Daily or more often, before run

ning engine, clean muffler area

(be sure muffler is cool) to remove

all grass and combustible debris.

If engine is equipped with a spark

arrestor screen, remove assembly

every 50 hours for cleaning and

■ inspection. Replace if damaged.