Engine maintenance – Craftsman 247.79452 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

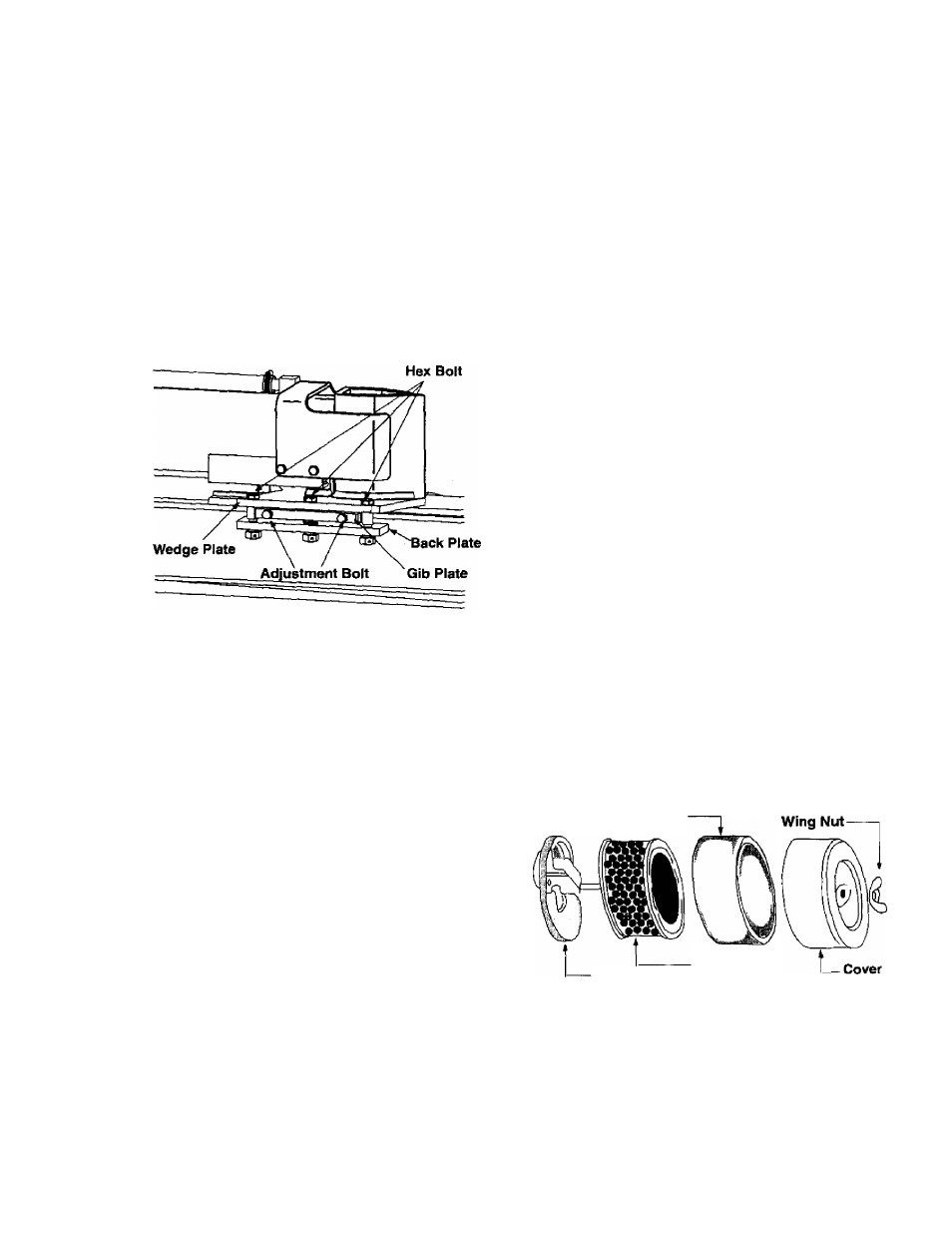

However, normal wear will occur. Periodically adjust

the bolts on the side of the wedge plate as follows to

eliminate excess space between the wedge plate and

the beam.

•

Loosen the lock nuts on the two adjustment

bolts on the side of the gib plate, located

beneath the splitting wedge. See Figure 13.

Turn the adjustment bolts in until snug, then

back them off slowly until the wedge assembly

will slide on the beam.

•

Tighten the lock nuts securely against the gib

plate to hold the adjustment bolts in this position.

Figure 13

Periodically remove and replace the “gibs” (spacers)

between the wedge plate and the back plate as

follows.

NOTE:

If desired, the gibs m aybe rotated and/or

turned over for even wear.

•

Remove the center bolt on top of the wedge

plate. Slide the gib plate out. See Figure 13.

•

Remove and replace the gibs. Reassemble the

gib plate, making certain flat washer is in place

above the gib plate.

•

Readjust the bolts on the side of the wedge

plate as instructed previously.

Engine Maintenance

Changing engine oil

•

Only use high quality detergent oil rated with

API service classification SF, SG or SH. Select

the oil's viscosity grade according to the

expected operating temperature. Referto

page 10 of this manual for viscosity chart.

•

Stop engine and wait several minutes before

checking oil level. With engine on level ground,

the oil must be to FULL mark on dipstick.

•

Change engine oil after the first five hours of

operation, and every 50 hours thereafter.

Change oil every 25 hours of operation if the

engine is operated under heavy load, or in high

ambient temperatures.

To drain oil

Drain oil while engine is warm. Follow the instructions

given below.

•

Remove oil drain plug and dipstick. Catch oil in a

suitabie container.

•

When engine is drained of all oil, replace drain

plug securely.

•

Refill with fresh oil. Refer to GAS AND OIL FILL

UP section of this manual.

•

Replace dipstick.

Air Cleaner

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and

performance. The air cleaner consists of a pre

cleaner or foam filter, and a paper filter.

Never run the engine without air cleaner completely

assembled.

1.

Service pre-cleaner after every 25 hours of use,

or at least once a season.

2.

Sen/ice filter every 100 hours of use, or at least

once a season.

3.

Service pre-deaner and filter more often under

dusty conditions.

•

Remove wing nut and cover.

•

Slide pre-cieaner off filter. Clean the inside of

base and cover thoroughly,

•

Clean pre-cleaner as follows: (See Figure 14.)

a. Wash in water and detergent solution, and

squeeze (do not twist) until all dirt is

removed.

b. Rinse thoroughly in clear water. Wrap in a

clean cloth and squeeze (do not twist) until

completely dry, or allow it to air dry.

c. Saturate with eng i ne oil and squeeze (don’t

twist) to distribute oil and remove excess oil.

Foam Filter

_

Paper Filter

Base

Figure 14

NOTE:

If the pre-cleaner is torn or dam aged in any

w ay, replace it.

•

if necessary, replace paper filter (do not attempt

to clean). Install new filter on base.

•

Slide pre-cleaner over filter.

•

Install cover and wing nut.

14