Carrier 48SX024-060 User Manual

Page 24

Table 5 — Rated Gas Inputs at Indicated Manifold Pressures

UNIT 48SS,SX

NUMBER

OF

ORIFICES

GAS SUPPLY PRESSURE

(in. wg)

MANIFOLD

PRESSURE

(in. wg)

NATURAL GAS

PROPANE*

Natural

Propane

Orifice

Drill

Size

Heating

Input

(Btuh)†

Orifice

Drill

Size

Heating

Input

(Btuh)†

Min

Max

Min

Max

Natural

Propane

018040, 024040, 030040

1

4.0

13.0

4.0

13.0

3.5

3.1

32

40,000

41

40,000

024060, 030060, 036060, 042060

2

4.0

13.0

4.0

13.0

3.5

3.3

40

56,000

47

54,000

030080, 036080, 042080,

048080, 060080

2

4.0

13.0

4.0

13.0

3.5

3.4

32

80,000

42

80,000

036100, 042100, 048100, 060100

2

4.0

13.0

4.0

13.0

3.5

3.7

30

95,000

40

95,000

036120, 042120, 048120, 060120

3

4.0

13.0

4.0

13.0

3.5

3.5

32

120,000

42

115,000

048140, 060140

3

4.0

13.0

4.0

13.0

3.5

3.4

31

136,000

40

133,000

* When a unit is converted to propane, different size orifices must be used. See separate natural-to-propane conversion kit

instructions.

†Based on altitudes from sea level to 2000 ft above sea level. For altitudes above 2000 ft: reduce input rating 4% for each

additional 1000 ft above 2000 ft. In Canada, from 2000 ft above sea level to 4500 ft above sea level, derate the unit 10%.

NOTE: Unit size 018 is 48SS only.

Measure Gas Flow (Natural Gas Units) — Minor adjust-

ment to the gas flow can be made by changing the man-

ifold pressure. The manifold pressure must be maintained

between 3.4 and 3.6 in. wg. If larger adjustments are re-

quired, change main burner orifices following the recom-

mendations of national and local codes.

NOTE: All other appliances that use the same meter must be

turned off when gas flow is measured at the meter.

Proceed as follows:

1. Turn off gas supply to unit.

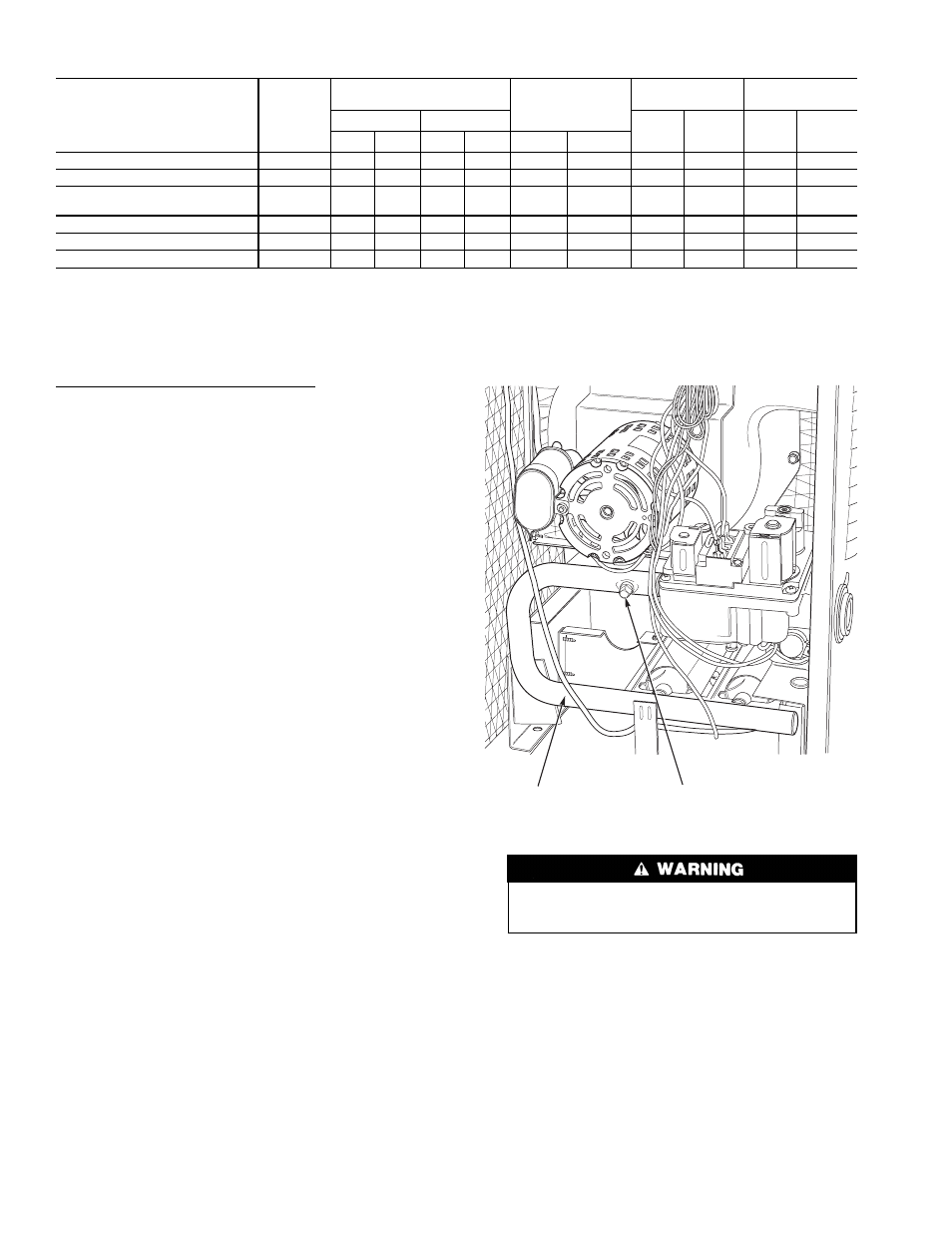

2. Remove pipe plug on manifold (see Fig. 24), then con-

nect manometer at this point. Turn on gas to unit.

3. Record number of seconds for gas meter test dial to make

one revolution.

4. Divide number of seconds in Step 3 into 3600 (number

of seconds in one hour).

5. Multiply result of Step 4 by the number of cu ft shown

for one revolution of test dial to obtain cu ft of gas flow

per hour.

6. Multiply result of Step 5 by Btu heating value of gas to

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 5. (Consult the local

gas supplier if the heating value of gas is not known.)

EXAMPLE: Assume that the size of test dial is 1 cu ft, one

revolution takes 30 seconds, and the heating value of the gas

is 1050 Btu/ft

3

. Proceed as follows:

1. 30 seconds to complete one revolution.

2. 3600 ÷ 30 = 120.

3. 120 x 1 = 120 ft

3

of gas flow/hr.

4. 120 x 1050 = 126,000 Btuh input.

If the desired gas input is 120,000 Btuh, only a minor change

in the manifold pressure is required.

Observe manifold pressure and proceed as follows to ad-

just gas input:

1. Remove cover screw over regulator adjustment screw on

gas valve.

2. Turn regulator adjustment screw clockwise to increase gas

input, or turn regulator adjustment screw counterclock-

wise to decrease input. Manifold pressure must be be-

tween 3.4 and 3.6 in. wg.

Unsafe operation of the unit may result if manifold

pressure is outside this range. Personal injury or unit

damage may result.

3. Replace cover screw cap on gas valve.

4. Turn off gas supply to unit. Remove manometer from pres-

sure tap and replace pipe plug on gas valve. Turn on gas

to unit and check for leaks.

MANIFOLD

PIPE PLUG

Fig. 24 — Burner Assembly

24