Operation – Taylor-Wharton EasyCarb User Manual

Page 5

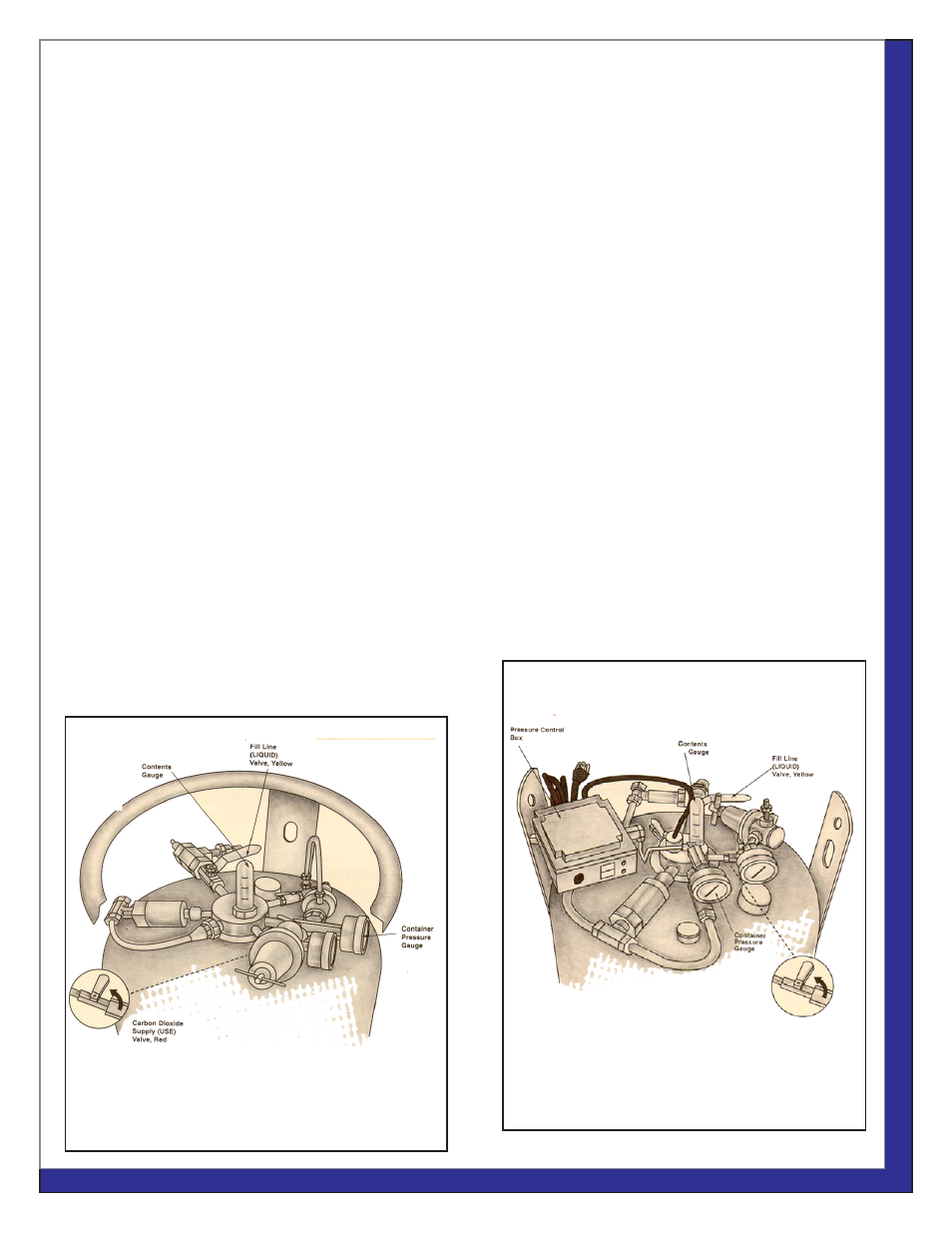

Operation

When your EasyCarb is installed connected to

your carbonation system, it operates without the

need for constant attention. Your supplier will set

the unit’s controls for proper operation. The

output pressure regulator setting may require

occasional adjustments to meet different soft

drink delivery requirements. The other valves

and controls on top of the container are used

only when it is necessary to turn off the gas flow

for maintenance, or if the system is damaged by

mishap.

Checking Container

The contents of the EasyCarb may be checked

by observing the position of a yellow indicator

band in the liquid level gauge. This contents

gauge is located on the top of the container, in

the center of the plumbing. It is a clear-plastic

scale with the yellow band visible behind the

scale. The position of the yellow band indicates

the liquid level in the container, and reads Full, ½

Full, Empty, etc. much like your auto fuel gage.

Checking Container

In some instances, you may need to observe

the pressure inside the EasyCarb. The

container pressure is displayed on a round

gauge with a dial/pointer located on the top

of the unit (see illustrations). To be sure you

are observing container pressure, look for

the gauge with a 0-400 psig (27.6 bar/2758

kPa) scale. Pressure in the container will

vary with the demand, but should always

remain between 125 psig (8.6 bar/862 kPa)

and 300 psig (20.7 bar/2068 kPa), which is

the normal operating range of the EasyCarb.

Isolating the Gas

Some EasyCarb models have an automatic

shut-off valve to close the output from the

container if the supply line plumbing devel-

ops a leak. Damage to the fill line or supply

line may result in a gas leak, usually indi-

cated by a hissing noise or loss of pressure.

There are two valves on the container that

should be closed immediately to stop the

loss of gas.