360 dvs series direct vent fireplaces, Termination clearances, General information assembling vent pipes – Vermont Casting 360DVS3 User Manual

Page 13: Twist lock pipes

14

360 DVS Series Direct Vent Fireplaces

10006326

Outside Corner

Inside Corner

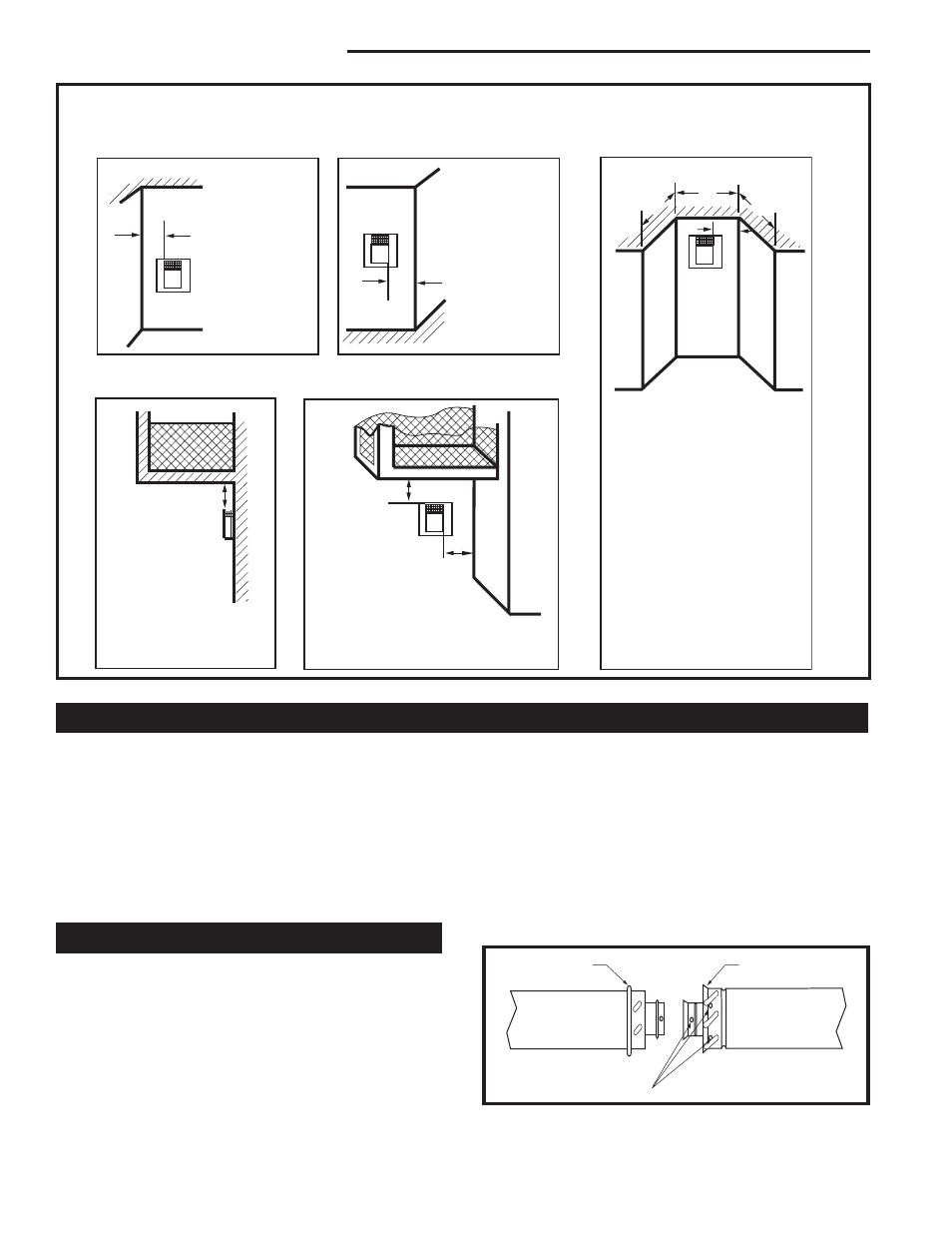

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

B =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

A

Balcony -

with no side wall

G =

Combustible &

Noncombustible

12"(305mm)

G

Balcony -

with perpendicular side wall

H = 24"(610mm)

J = 20"(508mm)

H

J

B

Recessed Location

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

584-15

Fig. 14 Termination clearances.

General Information Assembling Vent Pipes

Canadian Installations:

Venting system must be installed in accordance with the

current CSA-B149.1 installation code.

USA Installations:

The venting system must conform with local codes and/

or current National Fuel Gas Code ANSI Z223.1/NFPA

54.

Only venting components manufactured by CFM Corpo-

ration can be used in Direct Vent systems.

Twist Lock Pipes

When using twist-lock pipe, it is not necessary to use

sealant on the joints. The only areas of the venting

system that need to be sealed with high-temperature

silicone sealant are the collars on the fireplace and ter-

mination, and sliding joints of telescopic vent sections

used in the system.

To join the twist lock pipes together, align the beads

of the male end with the grooves of the female end.

While bringing the pipes together, twist the pipe until the

flange on the female end contacts the external flange

on the male end. It is recommended that you secure the

joints with three (3) sheet metal screws; however, this is

not mandatory with twist lock pipe.

NOTE: For ease of assembly, use a lubricant (Vaseline

or similar substance) on male end of twist lock pipe

prior to assembly.

Male End

Female End

Screw Holes

TWL100

Fig. 15 Twist lock pipe joints.