Carrier SINGLE PACKAGED ELECTRIC COOLING UNITS 50GX User Manual

Page 7

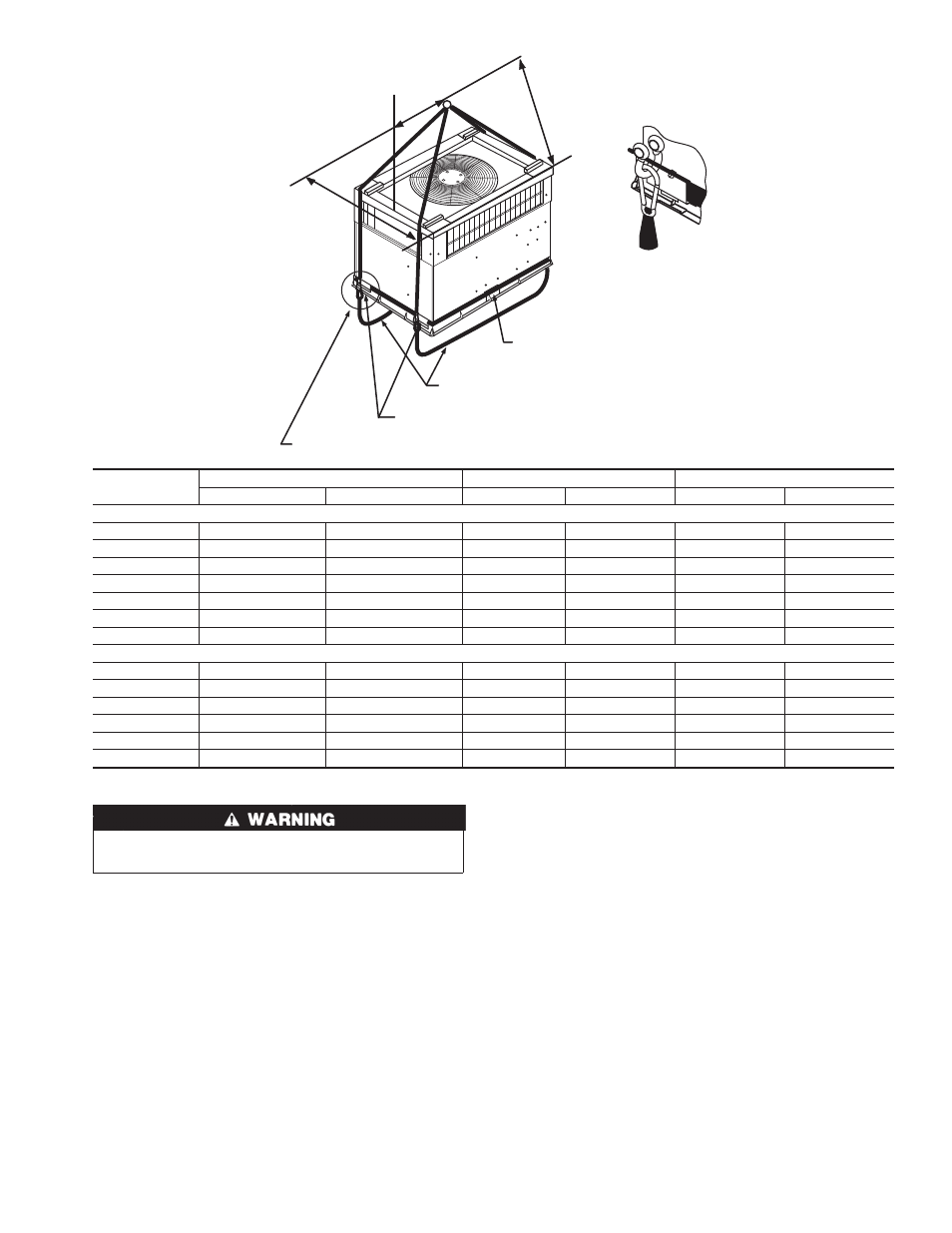

Lifting point should be directly over the center of gravity for

the unit.

Step 6—Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Models 50GS and 50GX dispose of condensate water through a

3/4 in. NPT fitting which exits through the base on the evaporator

coil access side. See Fig. 2 & 3 for location.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in ground-

level installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. lower than the drainpan

condensate connection to prevent the pan from overflowing (See

Fig. 7). When using a gravel apron, make sure it slopes away from

the unit.

Connect a drain tube using a minimum of 3/4 -in. PVC or 3/4 -in.

copper pipe (all field-supplied) at the outlet end of the 2-in. trap.

Do not undersize the tube. Pitch the drain tube downward at a

slope of at least 1-in. for every 10 ft. of horizontal run. Be sure to

check the drain tube for leaks. Prime trap at the beginning of the

cooling season start-up.

Step 7—Install Duct Connections

The unit has duct flanges on the supply- and return-air openings on

the side and bottom of the unit. For downshot applications the

ductwork can be connected to the roof curb. See Fig. 2 & 3 for

connection sizes and locations.

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weathertight and airtight seal. When electric heat is

installed, use fire proof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

from the unit discharge connection flange into the ductwork.

Fig. 6—Suggested Rigging

SIZE

MAXIMUM WEIGHT

A

B

lb.

kg

in.

mm.

in.

mm.

UNIT 50GS

018

276

125.2

20

508.0

13

330.2

024

282

127.9

19

482.6

13

330.2

030

280

127.0

19

482.6

14

355.6

036

290

131.5

20

508.0

14

355.6

042

316

143.3

19

482.6

14

355.6

048

346

156.9

20

508

17

431.8

060

411

186.4

19

482.6

16

406.4

UNIT 50GX

024

292

132.5

18.5

469.9

14.50

368.3

030

313

142.5

19.5

495.3

15.50

393.7

036

321

145.6

19.5

495.3

15.25

387.4

042

343

155.6

20.5

520.7

16.75

425.5

048

348

157.9

19.5

495.3

17.62

447.6

060

421

191.0

20.5

520.7

16.25

412.8

C99066

PLACE RIGGING BRACKET ASSEMBLY IN 4

RIGGING HOLES AND INSTALL TIE DOWN STRAP

AROUND PERIMETER OF UNIT AND THROUGH

SPACE IN BRACKET ASSEMBLY

INSTALL SAFETY STRAPS TO

RIGGING CLEVIS AT 4 RIGGING BRACKETS

TIGHTEN STRAPPING SECURELY

WITH TENSION BUCKLE

SEE DETAIL A

DETAIL A

SCALE 0.250

914-137"

(36"-54")

“A”

“B”

7